Six-bar bouncing combined-type wheel-leg mobile robot

A mobile robot and drive motor technology, applied in the field of robotics, can solve the problems of reducing the ability of the robot to cross ravines, the complexity of the swing deceleration mechanism, and the low energy conversion efficiency, and achieve a simple structure, self-resetting function, and less arm length restrictions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

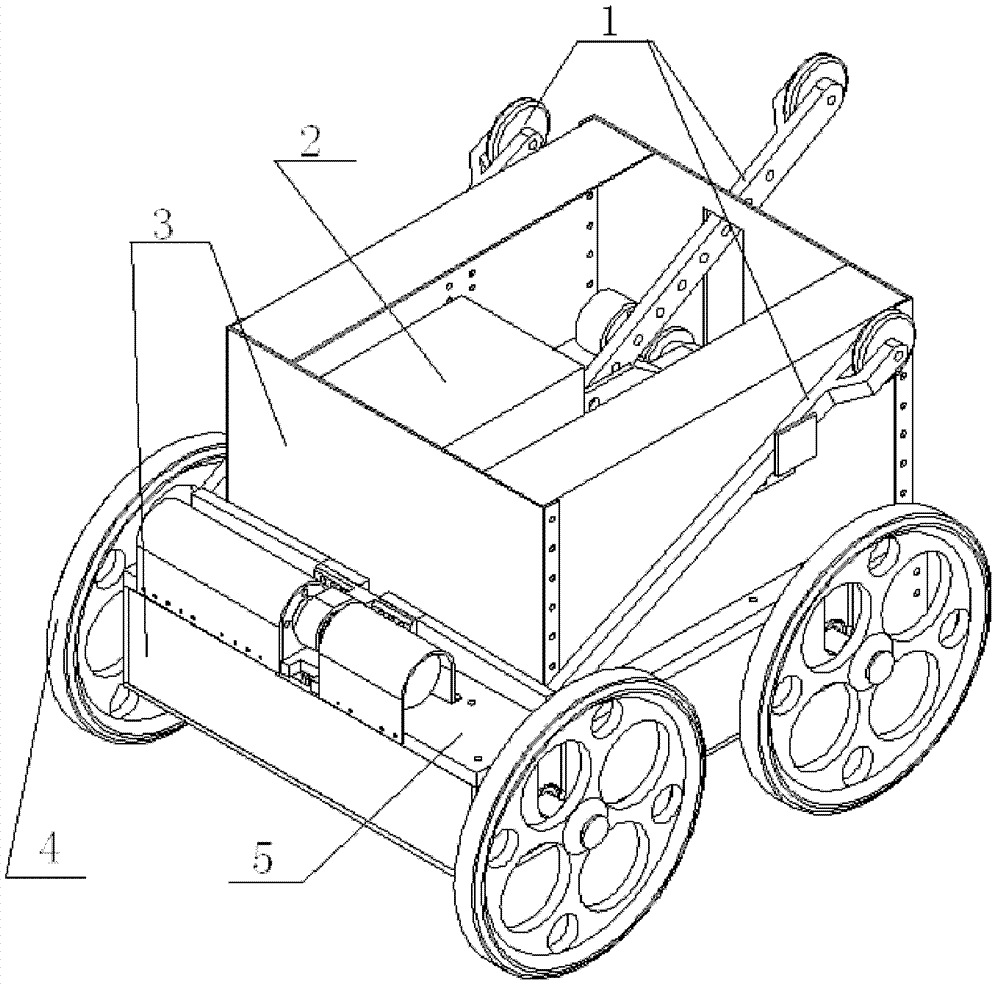

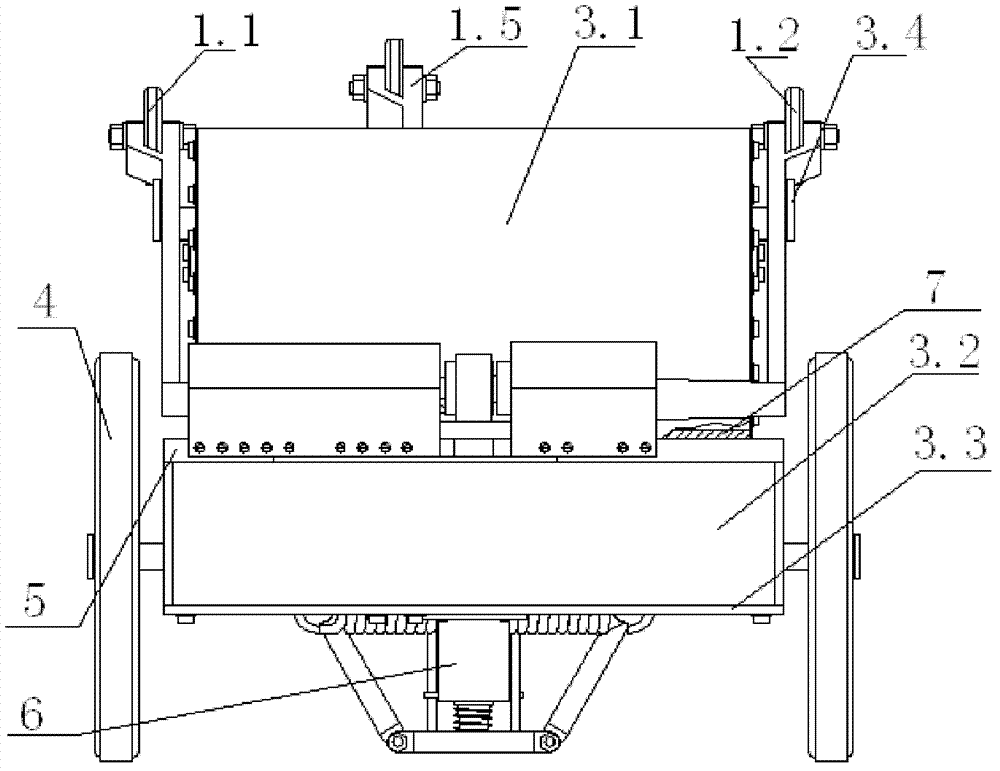

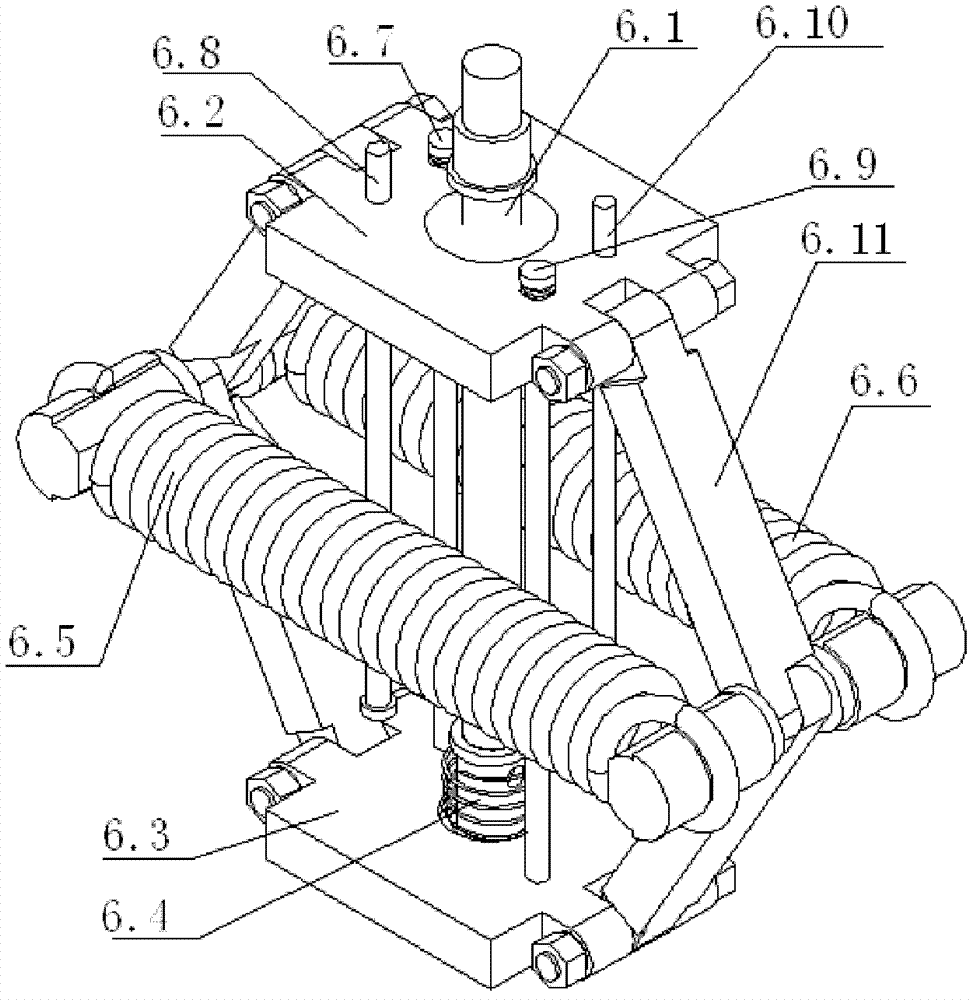

[0029] like figure 1 , figure 2 As shown, the robot of the present invention mainly includes a wheeled mobile mechanism 4, a bouncing mechanism 6, a car body 3, a front and rear swing arm mechanism 1, and a pan-tilt mechanism 2. like Figure 8 , Figure 9 As shown, the left front wheel 4.1, the left rear wheel 4.2, the right front wheel 4.3 and the right rear wheel 4.4 in the wheeled mobile mechanism are symmetrically installed respectively on both sides of the main board 5, and the left wheel drive motor 4.5 and the right wheel drive motor 4.6 pass through respectively Respective motor flanges are fixed on the main board 5 below. The transmission shaft of the left front wheel 4.1 passes through the left front wheel bearing 4.7, the left front wheel shaft connection sleeve 4.8 is connected with the first pulley 4.9, the transmission shaft of the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com