Method and device for removing hydrogen-containing impurities from germanium tetrachloride

A germanium tetrachloride and impurity technology, applied in germanium halide and other directions, can solve the problems of inability to effectively remove hydrogen-containing impurities, inability to remove hydrogen-containing impurities, etc., and achieve the effects of high industrial use value, convenient operation and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

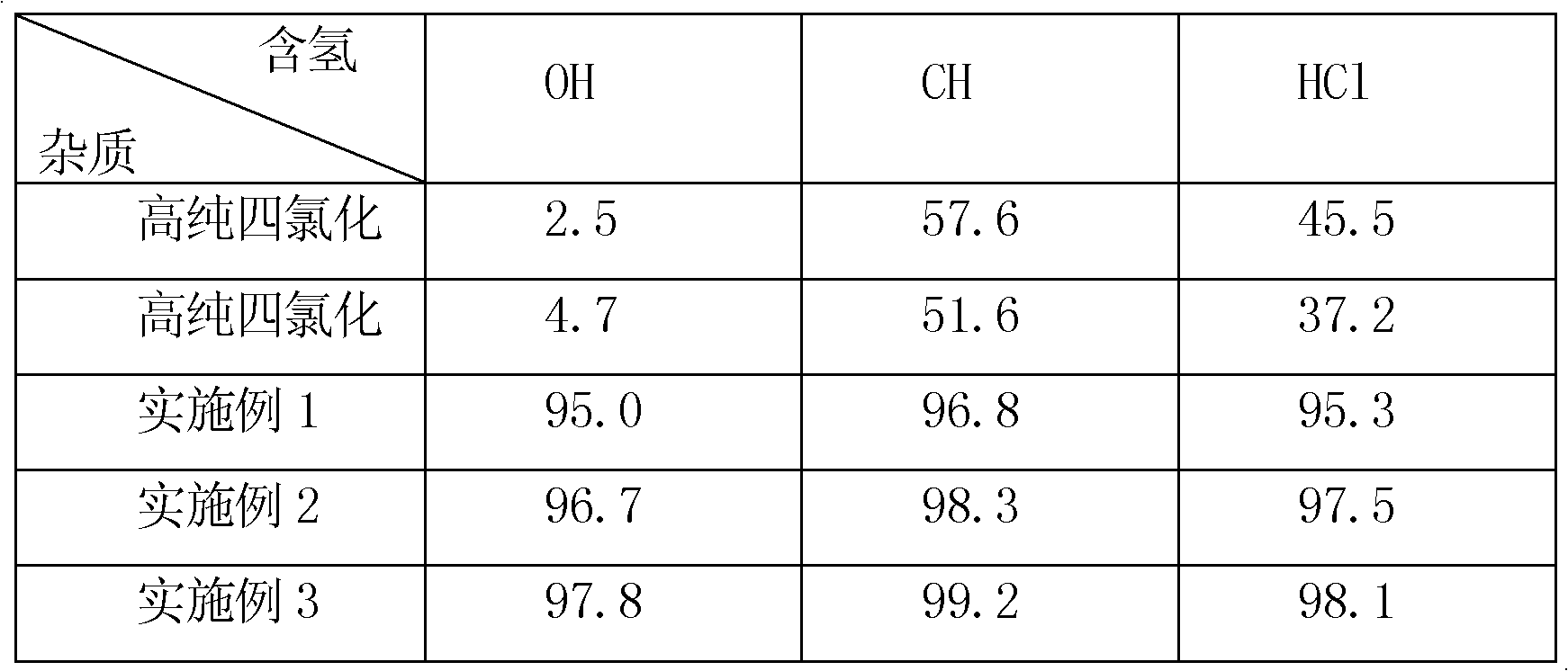

Embodiment 1

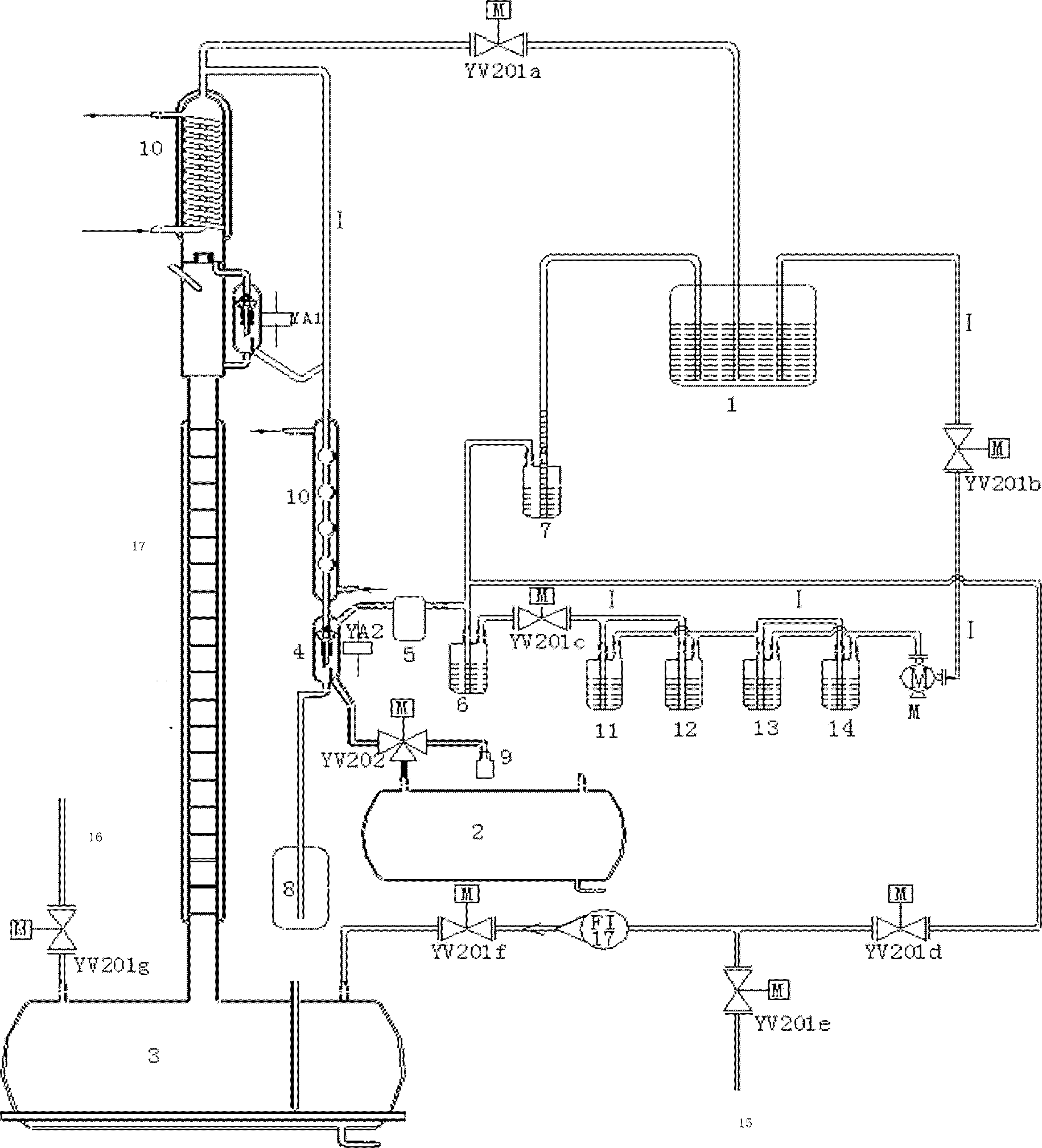

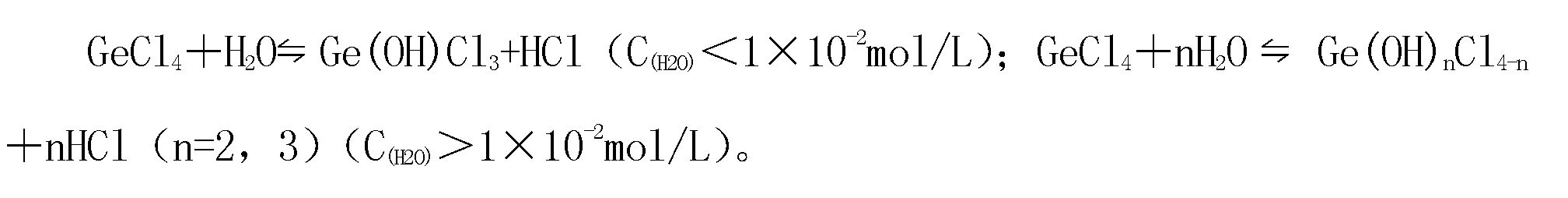

[0030] (1) Add germanium tetrachloride with a purity of 4N to 5N into the quartz rectification kettle, heat the rectification kettle to 75-83°C for rectification, make the germanium tetrachloride in a sub-boiling state, and feed The flow rate is 30-40L / h nitrogen, start the vacuum pump, and at the same time open the valves YV201e, YV201f, YV201c, YV201b, YV201a and YV201d in sequence, and run the vacuum system to make the hydrogen-containing impurities enter the exhaust gas absorption device through the pipeline I. The vacuum time is 6--10 hours;

[0031] (2) After completing the vacuuming operation process, continue to increase the temperature of the rectification kettle, and when all the sieve plates in the column of the rectification tower are boiling, start timing to perform the full reflux operation, and the total reflux time is 3-6h;

[0032] (3) After the full reflux process is over, turn on the electromagnets YA1 and YA2 at the same time, adjust the reflux ratio, and c...

Embodiment 2

[0038](1) 25L of germanium tetrachloride with a purity of 4N to 5N is added to the quartz rectification kettle 3 for rectification, and the temperature of the rectification kettle 3 is raised to 75° C. For high-purity nitrogen gas with a flow rate of 35L / h and a purity of 5N, start the vacuum pump, and at the same time open the valves YV201e, YV201f, YV201c, YV201b, YV201a and YV201d in sequence, and operate the vacuum system to allow hydrogen-containing impurities to enter the tail gas absorption device 1 through the pipeline I , the vacuuming time is 10 hours;

[0039] (2) After completing the vacuuming operation process, continue to increase the temperature of the rectification kettle, and when all the sieve plates in the column of the rectification tower are boiling, start timing and perform the total reflux operation, and the total reflux time is 4 hours;

[0040] (3) After the full reflux process is over, turn on the electromagnets YA1 and YA2 at the same time to adjust ...

Embodiment 3

[0042] (1) Add 30L of germanium tetrachloride with a purity of 4N to 5N into a quartz rectification kettle for rectification, raise the temperature of the kettle to 83°C, make the germanium tetrachloride in a sub-boiling state, and feed in a flow rate of 40L / h. High-purity nitrogen with a purity of 5.5N, start the vacuum pump, and at the same time open the valves YV201e, YV201f, YV201c, YV201b, YV201a and YV201d in sequence, and run the vacuum system to make the hydrogen-containing impurities enter the exhaust gas absorption device through the pipeline I. for 10 hours;

[0043] (2) After completing the vacuuming operation process, continue to increase the temperature of the rectification kettle, and when all the sieve plates in the column of the rectification tower are boiling, start timing and perform the total reflux operation, and the total reflux time is 5 hours;

[0044] (3) After the full reflux process is over, turn on the electromagnets YA1 and YA2 at the same time to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com