Main driving mechanism of intermediate-speed needling machine

A main drive, acupuncture machine technology, applied in acupuncture machines, transmission devices, mechanical equipment and other directions, can solve the problem of the probability of oil leakage, the unreasonable structure of the push rod seat, the inability to reduce the number of push rods, etc. Reasonable cost performance, optimized connecting rod design, and the effect of reducing the number of configurations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

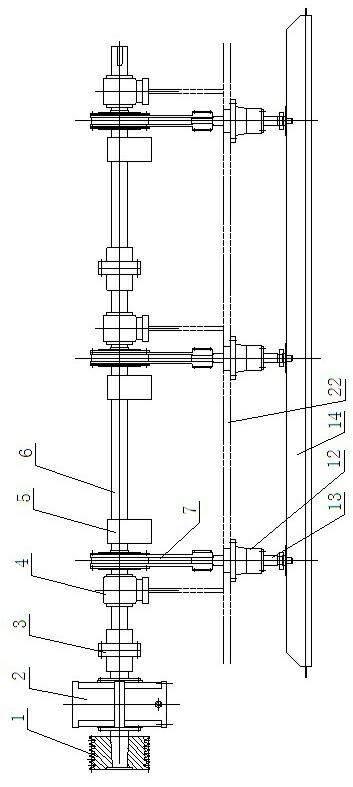

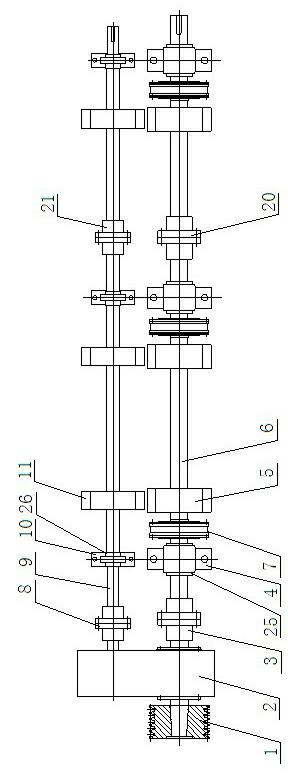

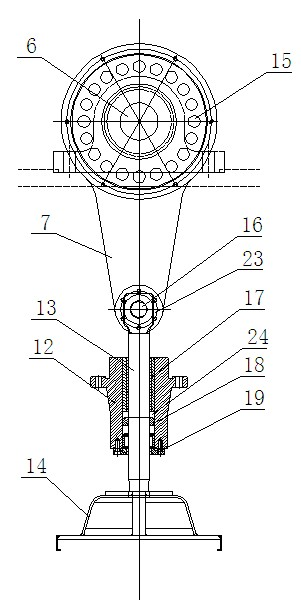

[0018] Such as figure 1 , 2 , 3, it is the main transmission mechanism of the medium-speed acupuncture machine, including a pulley 1, two camshafts 6 and two sub-spindles 9, two adjacent camshafts 6 are connected by the first coupling 20, adjacent The two sub-spindles 9 are connected by a second coupling 21 . The pulley 1 is connected to the transfer case 2, one output end of the transfer case 2 is connected to the camshaft 6 at the end through the main shaft coupling 3, and the other output end of the transfer case 2 is connected to the end camshaft through the countershaft coupling 8 The sub-spindle 9 is connected to the sub-spindle 9 and the camshaft 6 is arranged in parallel, the sub-spindle 9 and the camshaft 6 are arranged on the same side of the transfer case 2, and the rotation direction of the sub-spindle 9 and the camshaft 6 are opposite.

[0019] One to two vertically arranged connecting rods 7 are respectively arranged on each camshaft 6, and the upper end of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com