Wear-resistant alloy raking tooth for railway ballast-cleaning machines

A wear-resistant alloy and sieve cleaning technology, which is applied in the field of wear-resistant alloy teeth, can solve problems such as short service life, low operating efficiency, and large consumption, and achieve improved wear resistance, extended service life, and improved impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

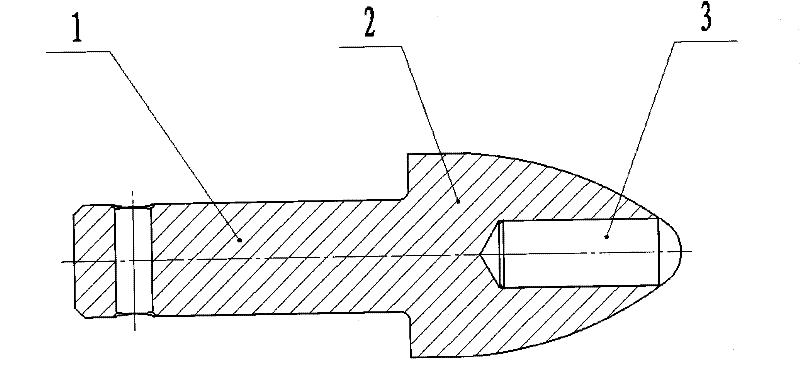

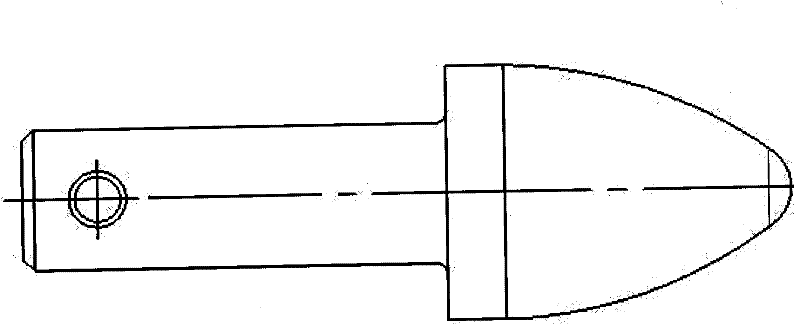

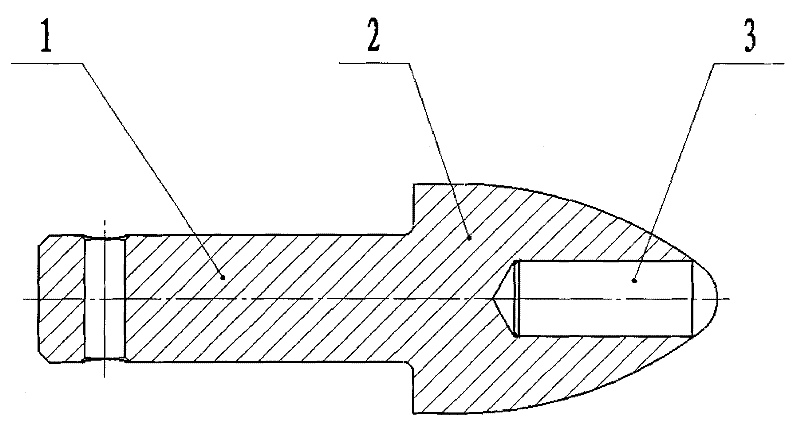

[0015] Below in conjunction with accompanying drawing, the present invention is further described: as figure 1 , 2 The wear-resistant alloy gear used for the railway screen cleaning locomotive shown in , includes a tooth handle 1 and a tooth head 2 formed by integral die forging, and a tooth tip 3 that is press-fitted with the tooth head 2 and inserted into the front end of the tooth head 2, The tooth head and tooth tip are compounded by interference pressing, which improves the compounding process of cemented carbide and improves the wear resistance and impact performance of the alloy gear.

[0016] The tooth shank 1 and the tooth head 2 are made of grade: 60Si2Mn alloy steel; the tooth tip 3 is made of grade: YG8~YG18 hard alloy. The tooth shank 1, the tooth head 2 and the tooth tip 3 are assembled into a whole. The use of new hard alloy materials has significantly improved the wear resistance of the racking teeth.

[0017] Such as figure 1 , 2 As shown, the outer conto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com