Flexible support structure of pre-stress anchor rod for lattice type frame and construction method of flexible support structure

A supporting structure and prestressing technology, which is applied in basic structure engineering, excavation, sheet pile wall, etc., can solve the problems of insufficient anti-overturning ability, poor overall stability, poor seismic performance, etc., to reduce soil erosion and improve seismic performance. , the effect of less disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

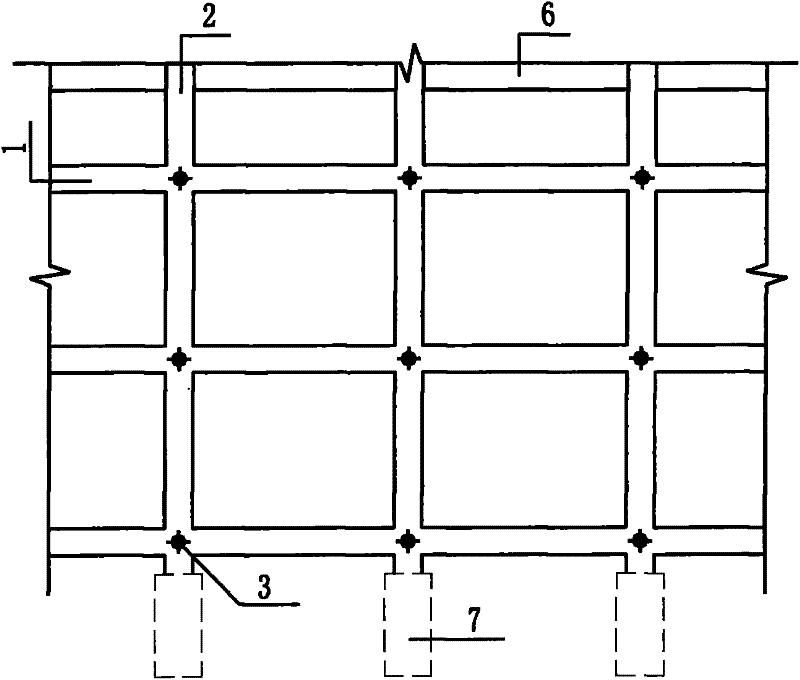

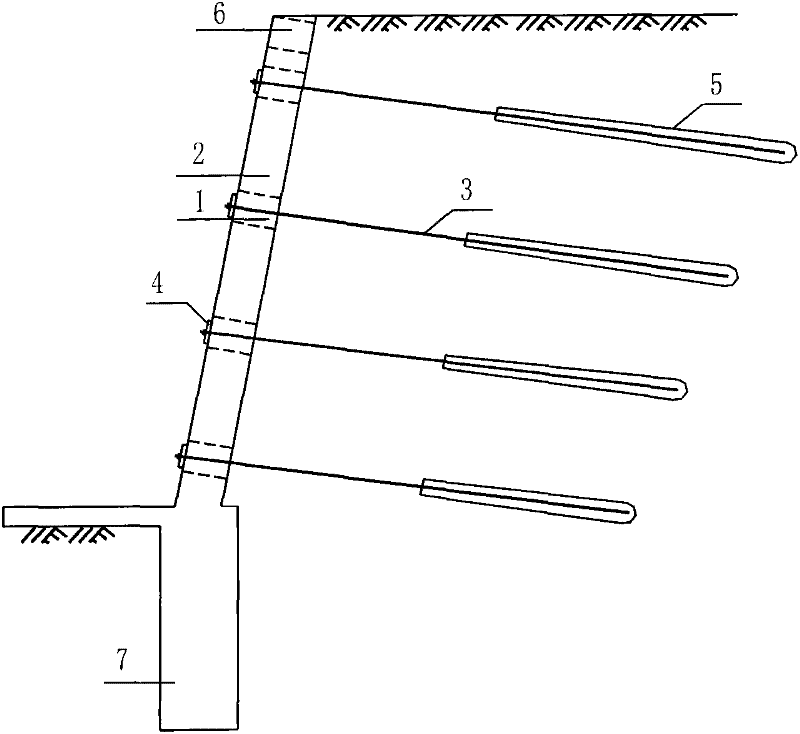

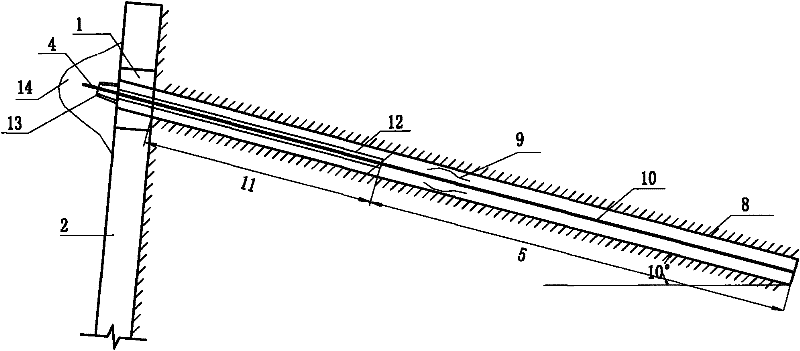

[0015] The present invention is a lattice frame prestressed bolt flexible support structure and its construction method. In the support structure, the beam 1 and the column 2 form a lattice frame, and the prestressed anchor 3 passes through the intersection of the beam 1 and the column 2. position, wrap cement mortar around the anchoring section 5 of the prestressed anchor 3, coat a layer of anti-corrosion material on the free section 11 of the prestressed anchor 3, and set a PVC plastic sleeve 12 outside the anti-corrosion material. Cement mortar is wrapped around the casing 12, and the anchor head 4 anchors the end of the prestressed anchor rod 3 at the intersection of the beam 1 and the column 2, and the earth pressure on the beam 1 and column 2 is transmitted to the prestressed The anchor section 5 of the anchor rod 3 is anchored in the stable soil layer through the anchor section 5 .

[0016] The inclination angle of the anchor rod formed by the prestressed anchor rod 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com