Fuel-oil atomizing nozzle and gas turbine with same

A fuel atomization and nozzle technology, applied in the field of gas turbines, can solve problems such as easy coking, uneven distribution of fuel oil, poor nozzle atomization effect, etc., and achieve uniform distribution and good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

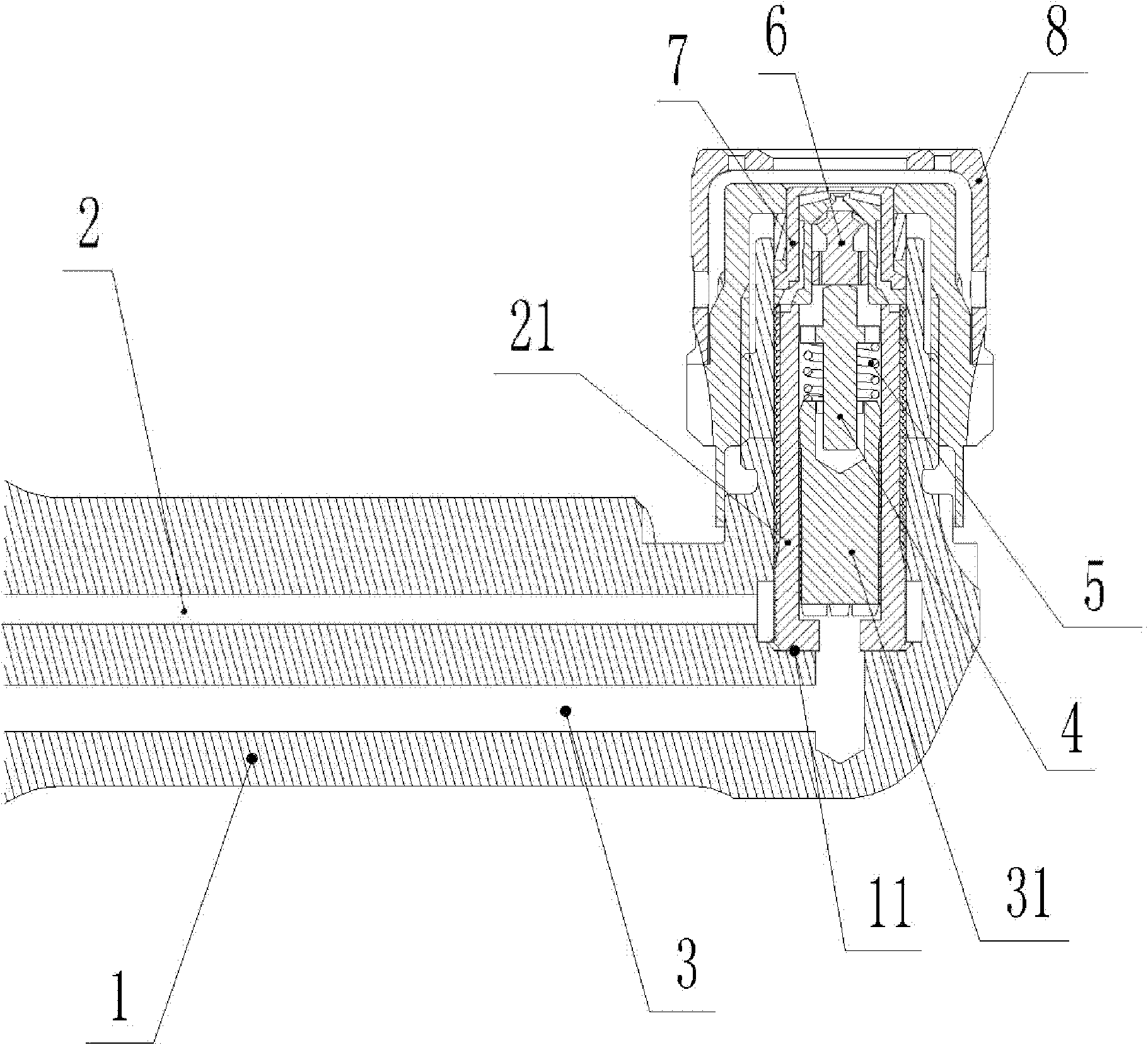

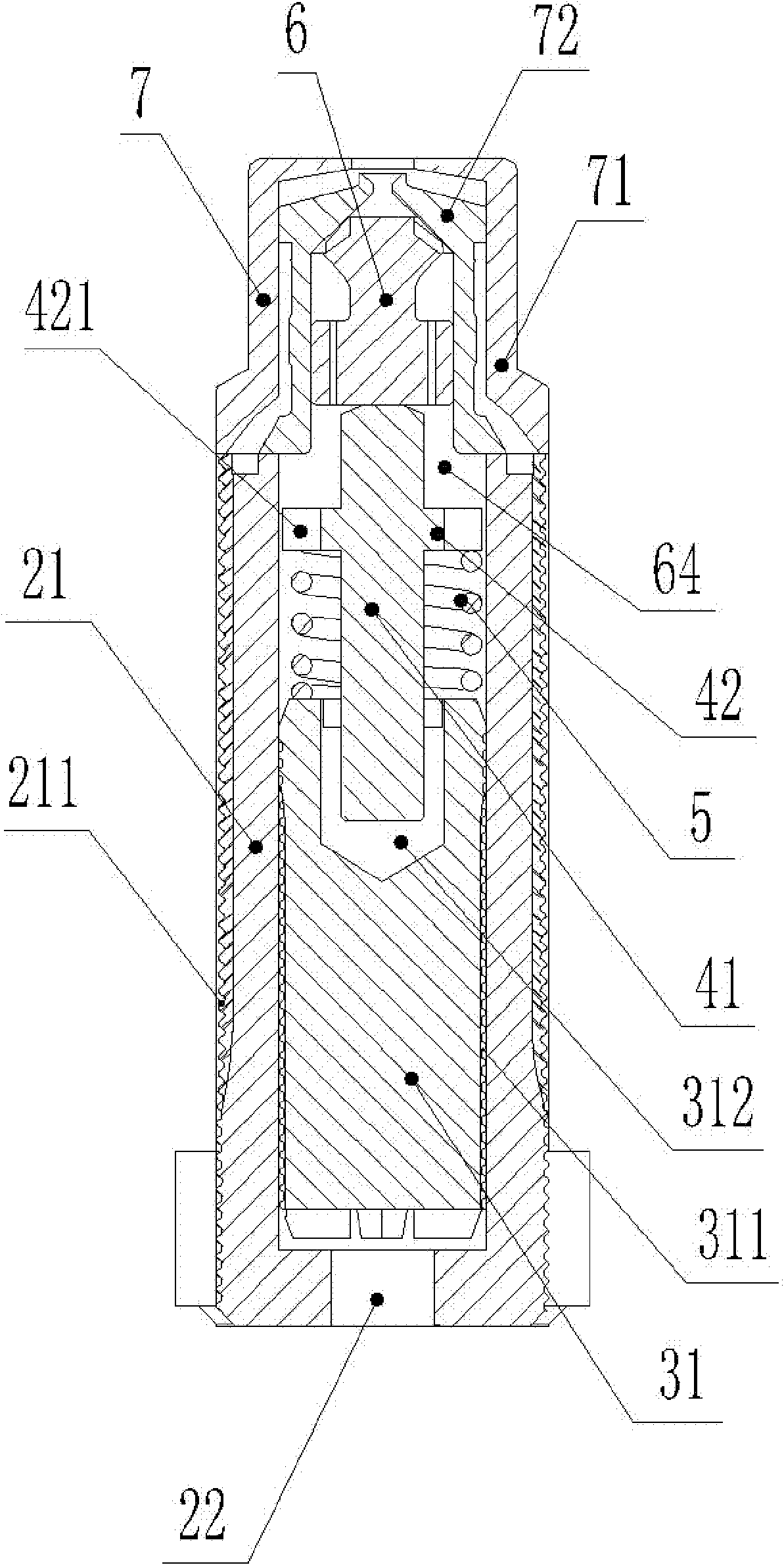

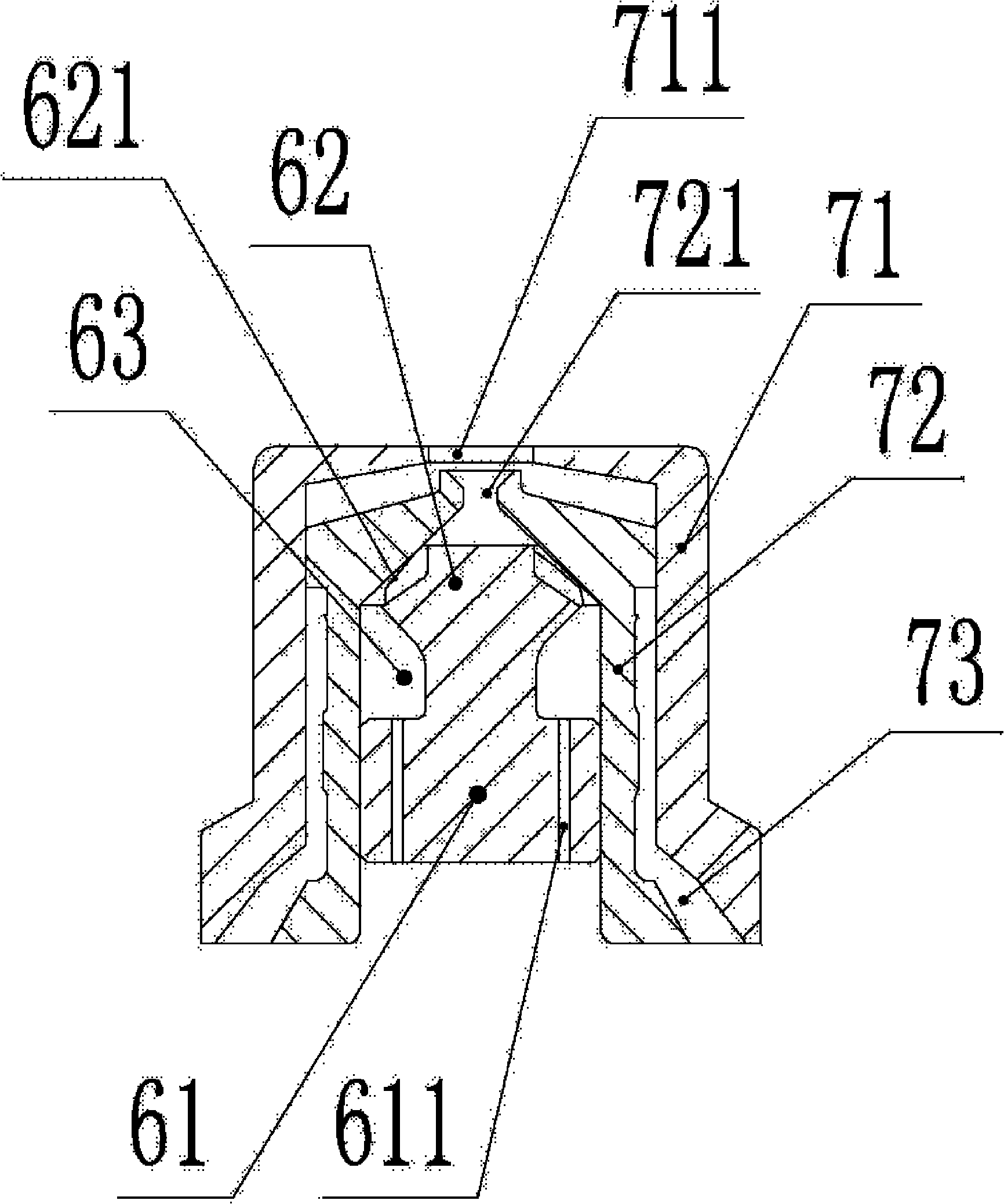

[0021] see figure 1 , a fuel atomizing nozzle, including a nozzle body 1, an air filter 21, an oil filter 31, a spring bracket 4, a spring 5, a swirler 6, a fuel nozzle 7 and a nozzle cover 8.

[0022] The nozzle body 1 has an L-shaped structure. Inside the long arm of the nozzle body 1, a fuel oil inlet pipe 3 and an air inlet pipe 2 are opened. The fuel inlet duct 3 and the air inlet duct 2 are arranged in parallel. Both the fuel oil inlet pipe 3 and the air inlet pipe 2 are round pipes. The inlet end of the fuel oil inlet pipeline 3 is provided with a member for connecting to the fuel supply device (not shown in the drawings). The inlet end of the air intake duct 2 is provided with a member for connecting an air supply device (not shown in the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap