Integrated detection method and device of rigidity, flexibility and wrinkle resistance of fabrics

A detection device and a wrinkle resistance technology are applied in the field of the integrated detection method and device of fabric rigidity, flexibility and wrinkle resistance, which can solve the problems of difficult judgment, affecting the test efficiency, and no purchase, and achieves simple operation and high detection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

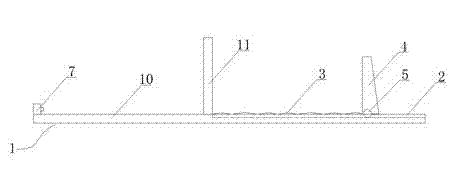

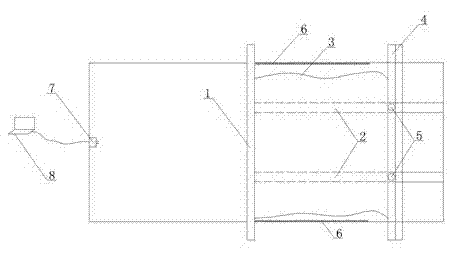

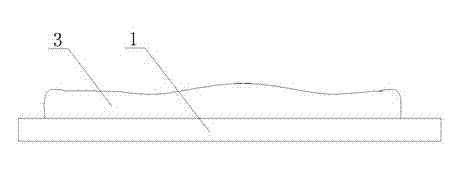

[0034] Such as figure 1 , figure 2As shown, the integrated testing device for fabric rigidity, flexibility and wrinkle resistance of the present invention includes a detection platform 1, and the detection platform 1 includes a flat panel 10, and a vertical panel 11 vertically arranged in the middle of the flat panel 10, the flat panel 10 and the vertical panel 11 An inverted T-shaped detection platform is formed, and the detection platform 1 is preferably made of a transparent material. In the present embodiment, organic glass is used. The thickness of the detection platform 1 (i.e. the thickness of the plane plate 10) is 1 cm, the length of the horizontal plane is 46 cm, and the width is 21 cm. The height of panel 11 is 9cm, and the right side of vertical panel 11 is cloth carrying platform, and length is 25cm, is provided with two parallel chutes 2 along the length direction on cloth carrying platform, in the present embodiment, chute 2 is arranged on The length of the ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com