Optimization design method of blades of wind turbine based on topology optimization of structure

A wind turbine blade and optimization design technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of increased blade load, heavy blade mass, affecting the overall operation efficiency of wind turbines, etc., to achieve the optimization of anti-fatigue performance, The effect of improving load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

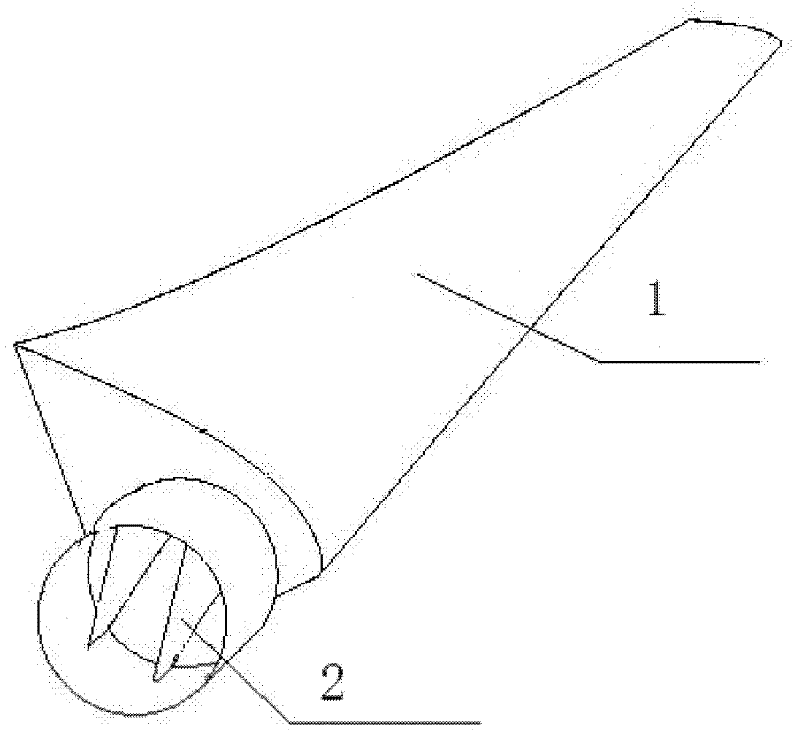

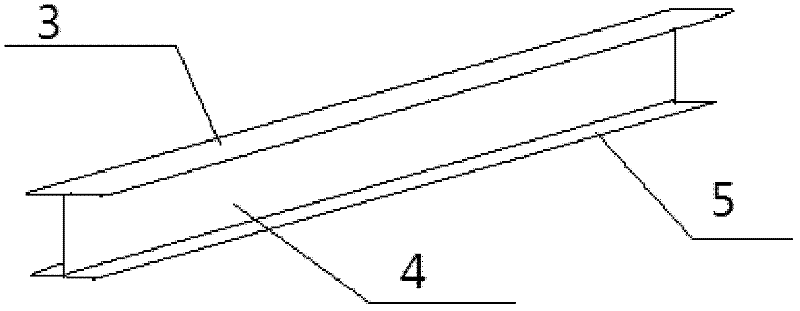

[0035] In an exemplary embodiment of the present invention, the main structure of a horizontal axis wind turbine blade includes a web 4 , upper and lower spar caps 3 , 5 and a skin 1 .

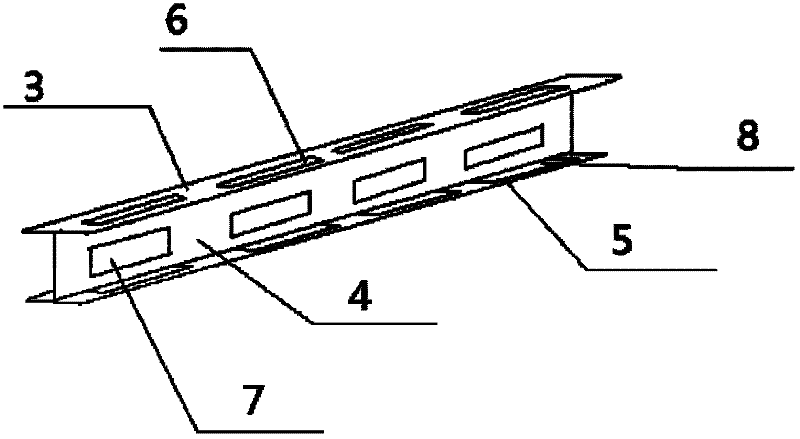

[0036] In this embodiment, holes are provided on the web 4 and the upper and lower spar caps 3, 5 along the radial direction of the blade. image 3 It is a structural schematic diagram of the horizontal axis wind turbine blade web and spar cap according to the embodiment of the present invention. Such as image 3 As shown, the opening may be a rectangular opening. The number, size and arrangement position of the rectangular openings are determined according to the optimization and verification results. By setting reasonable openings on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com