System and method of displacement volumes in composite members

A composite component and displacement technology, applied in the field of systems and methods for displacement volume in composite components, can solve problems such as expensive and expensive transportation costs, and achieve the effects of reduced transportation, reduced materials, and enhanced flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

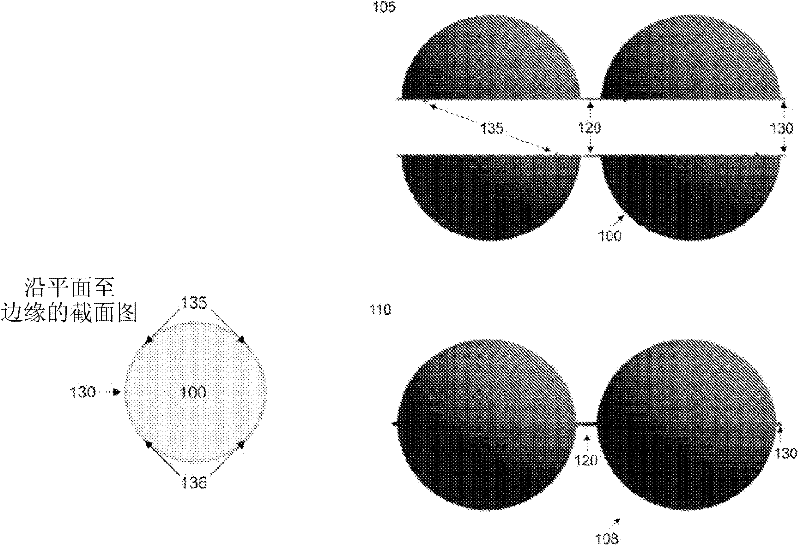

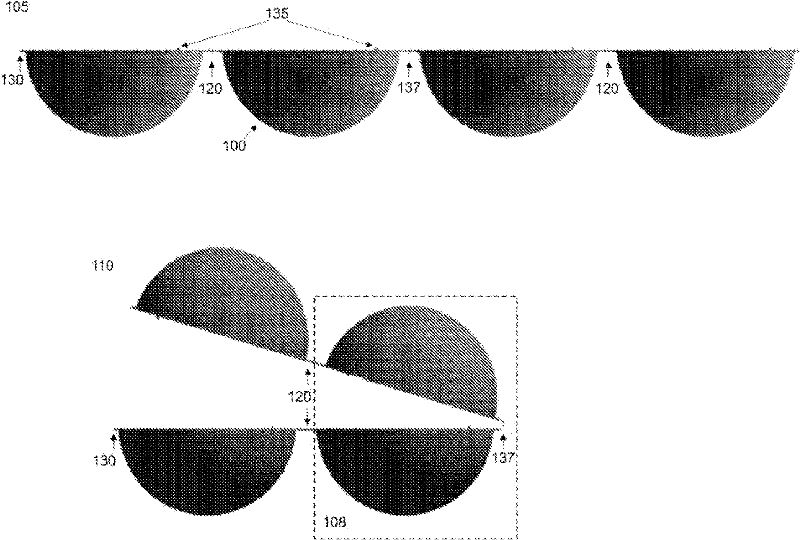

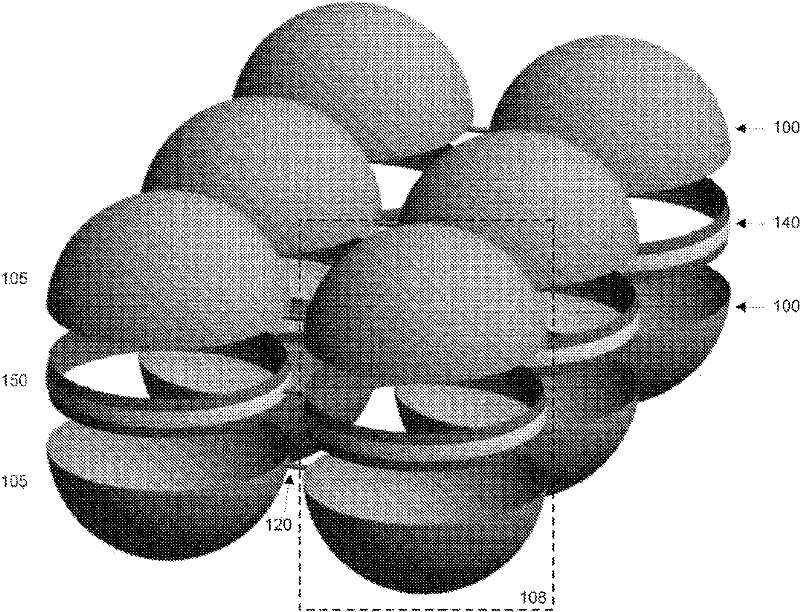

[0024] The present invention comprises a displacement system which solves several problems relating to the flexibility of displacement volumes within composite members, thereby enabling the introduction of the system into a significantly wider range of applications.

[0025] The present invention further solves several problems existing with respect to strength, transport and assembly, resulting in a cost effective high quality product in terms of material reduction, transport reduction and precise assembly.

[0026] All current tests and studies are based on the exact homogeneous geometric arrangement of the displacement volume and the position of the building steel relative to the displacement volume and the overall geometry of the building element. In order to be able to use these tests and studies for validation in practical implementations, it is clear that the displacement system must enable precise placement of the displacement volume. If the volumes lie within a precis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com