Magneto-impedance sensor element and method for manufacturing the same

一种传感器元件、磁阻抗的技术,应用在磁阻抗传感器元件,小型化,薄型化领域,能够解决不能充分发挥磁阻抗等问题,达到解除细微加工性、扩大选择范围的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

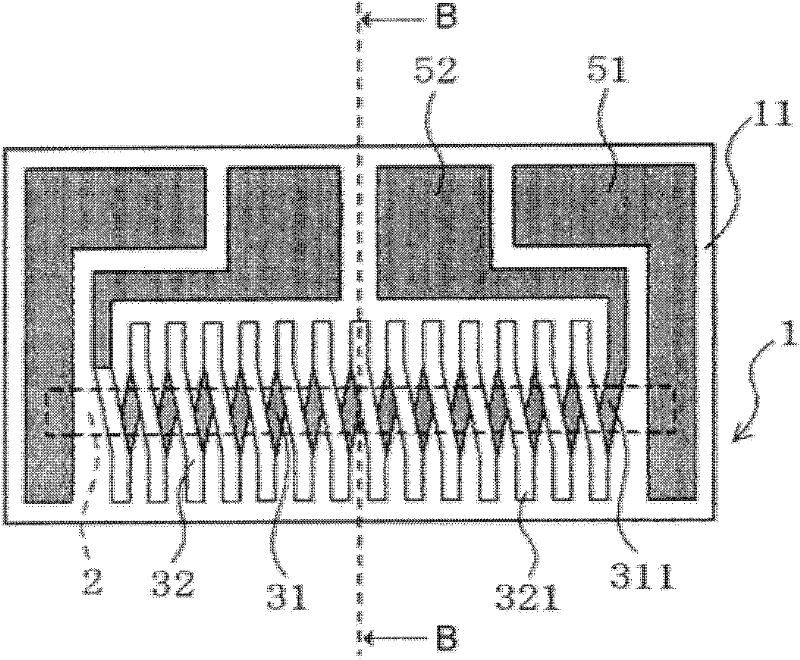

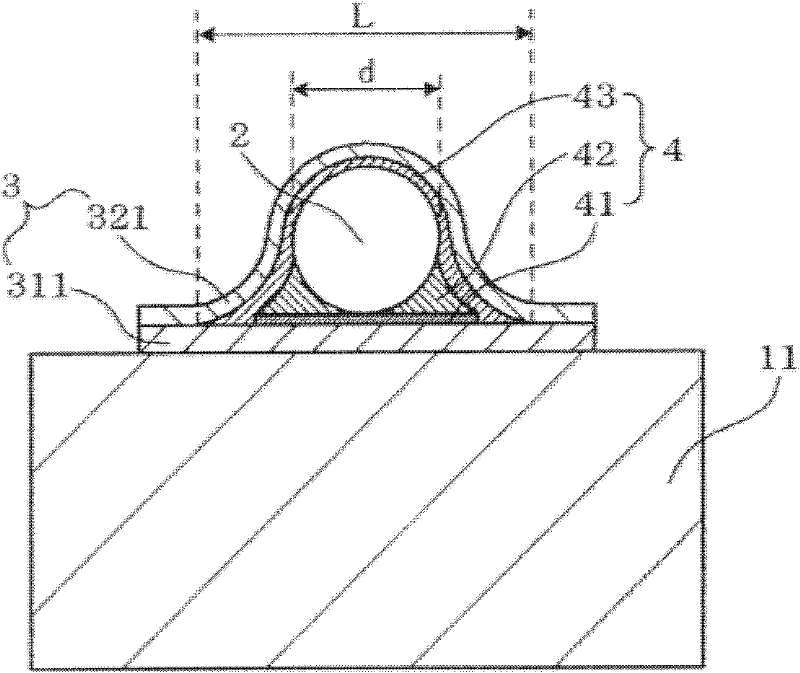

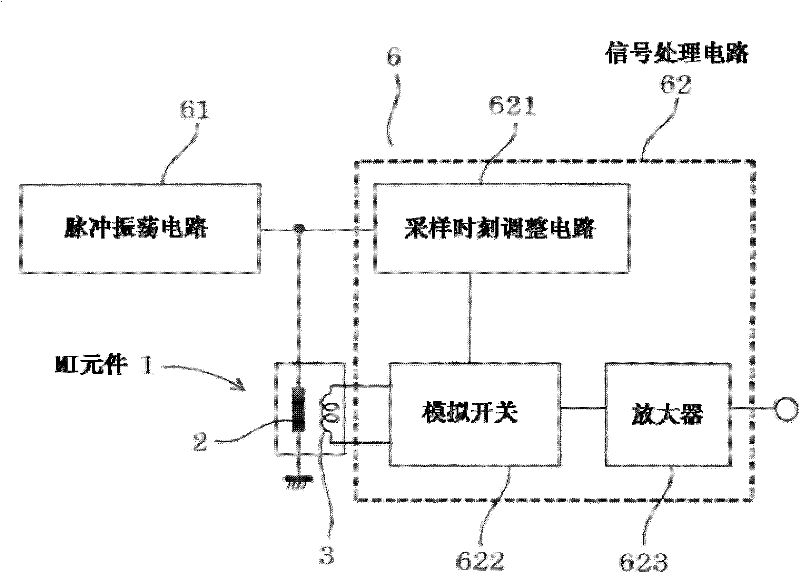

[0127] use figure 1 as well as figure 2 A first embodiment of the planar MI element of the present invention will be described. figure 1 is a conceptual diagram showing the front of the planar MI element 1, figure 2 Yes figure 1 View of the B-B line.

[0128] like figure 1 , figure 2As shown, the magneto-impedance sensor element 1 of the present invention includes a substrate 11 made of a non-magnetic material. In addition, a planar pattern 31 composed of a plurality of first conductor films 311 arranged on a flat surface of the substrate surface is also included. It also includes amorphous wires 2 having a circular cross section arranged along the arrangement direction of the planar patterns 31 across the plurality of first conductor films 311 . Furthermore, an insulator 4 for fixing the amorphous wire 2 to the planar pattern 31 while covering the outer peripheral surface of the amorphous wire 2 is also included.

[0129] In addition, it also includes a three-d...

Embodiment 2

[0174] The material of the amorphous wire in embodiment 2 is the same as that of embodiment 1 and the conventional example, the diameter of the amorphous wire is reduced from 30 μm to 10 μm, and the length is shortened from 0.9 mm to 0.57 mm, and the length of the substrate is also reduced from 1.0mm shortened to 0.6mm. Other conditions are all the same as in Example 1.

[0175] As a result, the circle-equivalent diameter of the detection coil of Example 2 is about 19 μm, which is significantly smaller than that of Example 1, which is about 43 μm, and the height of the substrate as a whole can be further reduced. In addition, the proximity index n=circle-equivalent diameter of the detection coil / diameter of the amorphous wire is n=1.9 in Example 1, which is not as good as in Example 1, but it is closer to winding than n=2.2 in the conventional example.

[0176] Further, L / d=2.8, within the range of 1.3-5.

[0177] Also, the sensitivity of the MI element in Example 2 was 49 m...

Embodiment 3

[0184] This example is a modified example of the configuration of the insulator 4 . like Figure 5 As shown, in this example, the planar insulating portion 41 and the amorphous wire fixing portion 42 are integrally formed at the same time.

[0185] In this case, since the step of forming the planar insulating portion 41 can be omitted, the manufacturing process of the magnetoresistance sensor element 1 becomes simple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com