Lifting appliance special for beam of large press

A technology for presses and beams, applied in the field of presses, can solve problems such as hidden dangers of lifting and damage to steel wire ropes, and achieve the effects of avoiding hidden dangers, reducing occupied area, and having a simple and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

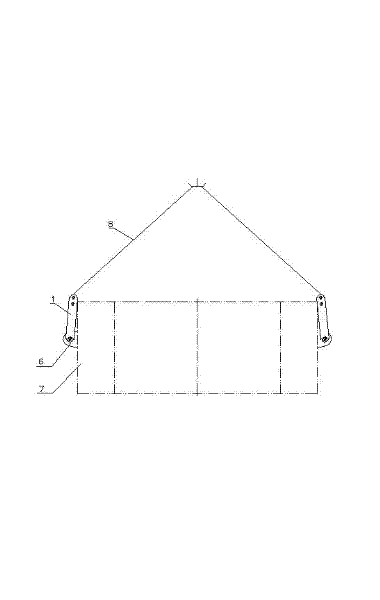

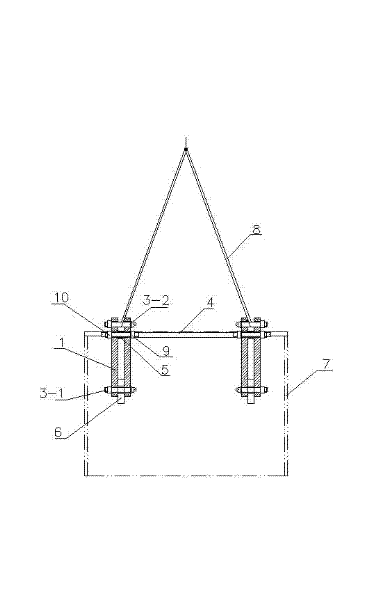

[0012] Such as figure 1 , figure 2 As shown, a special spreader for large press beams, the spreader includes 4 sets of the same lifting lug clamps, each set of 2 sets of lifting lug clamps are set on the 2 lifting lugs on one side of the beam 7 as a group, and the wire rope 8 passes through The connecting lugs form a four-point pull to the crossbeam 7, so as to realize the smooth lifting of the crossbeam 7.

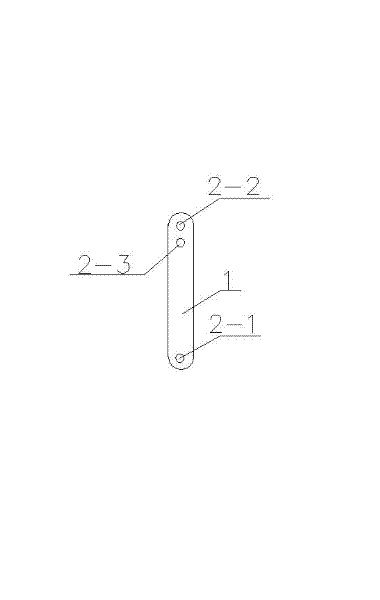

[0013] Such as figure 2 As shown, each set of lug clips includes two identical pull plates 1 .

[0014] Such as image 3 As shown, the lower part of the surface of each pull plate 1 is provided with a lifting eye hinge hole 2-1, and the upper part of the surface of the pull plate is provided with a load-bearing bolt hole 2-2.

[0015] Such as figure 1 , figure 2 As shown, when the pull plate 1 is produced, the distance between the hinged hole 2-1 of the lifting lug and the load-bearing bolt hole 2-2 must be greater than the distance between the lifting lug 6 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com