Defluorination method for zinc sulphate solution

A zinc sulfate solution and removal technology is applied in the field of removing fluorine in zinc sulfate solution and defluorination treatment of high-fluorine zinc sulfate solution, which can solve the problem of large amount of fluorine absorbing and removing agent, limited fluorine adsorption capacity, and removal effect. Not ideal, etc., to achieve the effect of high recovery rate and quality, strong pertinence, and short and easy defluorination process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

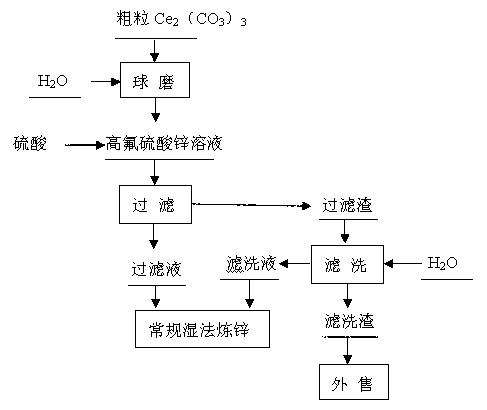

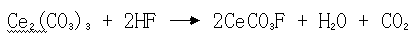

[0024] A method for removing fluorine in zinc sulfate solution, including the following sequential steps: A. Ball milling process: using a ceramic ball mill, adding coarse Ce into the ball mill 2 (CO 3 ) 3 , Add water in the ball mill, Ce in the ball mill 2 (CO 3 ) 3 The mass ratio with water is 1:1, and Ce 2 (CO 3 ) 3 Wet milling, ball milling makes Ce 2 (CO 3 ) 3 The particle size is less than 1 micron, so that the Ce in the ball mill 2 (CO 3 ) 3 A slurry is formed, and the slurry is used for precipitation and defluorination process; B. Precipitation and defluorination: Add 243Kg (dry weight) of the slurry of step A to 60 m 3 Ce added in zinc sulfate solution with fluorine content of 0.311g / L and pH value of 5.0 2 (CO 3 ) 3 The mass ratio of the fluorine in the zinc sulfate solution is 13:1. Add sulfuric acid. The sulfuric acid is an industrial sulfuric acid with a mass percentage concentration> 92%. Adjust the pH of the zinc sulfate solution to 3.0 and control the temperature of...

Embodiment 2

[0026] A method for removing fluorine in zinc sulfate solution, including the following sequential steps: A. Ball milling process: using a ceramic ball mill, adding coarse Ce into the ball mill 2 (CO 3 ) 3 , Add water in the ball mill, Ce in the ball mill 2 (CO 3 ) 3 The mass ratio to water is 1.5:1, and the Ce 2 (CO 3 ) 3 Wet milling, ball milling makes Ce 2 (CO 3 ) 3 The particle size is less than 1 micron, so that the Ce in the ball mill 2 (CO 3 ) 3 A slurry is formed, and the slurry is used for precipitation and defluorination process; B. Precipitation and defluorination: Add 361Kg (dry weight) of the slurry of step A to 60 m 3 Ce is added to zinc sulfate solution with fluorine content of 0.43g / L and pH value of 5.2 2 (CO 3 ) 3 The mass ratio of the fluorine in the zinc sulfate solution is 14:1. Add sulfuric acid. The sulfuric acid is an industrial sulfuric acid with a mass percentage concentration> 92%. Adjust the pH value of the zinc sulfate solution to 4.0 and control the te...

Embodiment 3

[0028] A method for removing fluorine in zinc sulfate solution, including the following sequential steps: A. Ball milling process: using a ceramic ball mill, adding coarse Ce into the ball mill 2 (CO 3 ) 3 , Add water in the ball mill, Ce in the ball mill 2 (CO 3 ) 3 The mass ratio to water is 2:1, and Ce 2 (CO 3 ) 3 Wet milling, ball milling makes Ce 2 (CO 3 ) 3 The particle size is less than 1 micron, so that the Ce in the ball mill 2 (CO 3 ) 3 A slurry is formed, and the slurry is used for precipitation and defluorination process; B. Precipitation and defluorination: Add 434Kg (dry weight) of the slurry of step A to 60 m 3 Ce is added to zinc sulfate solution with fluorine content of 0.482g / L and pH value of 5.4 2 (CO 3 ) 3 The mass ratio of fluorine in the zinc sulfate solution is 15:1. Add sulfuric acid. The sulfuric acid is an industrial sulfuric acid with a mass percentage concentration> 92%. Adjust the pH of the zinc sulfate solution to 4.5 and control the temperature of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com