Method for judging etching ending point through pressure variation

A technology of etching termination and pressure, applied in the direction of gaseous chemical plating, coating, electrical components, etc., can solve the problem of high cost and achieve the effect of low cost and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

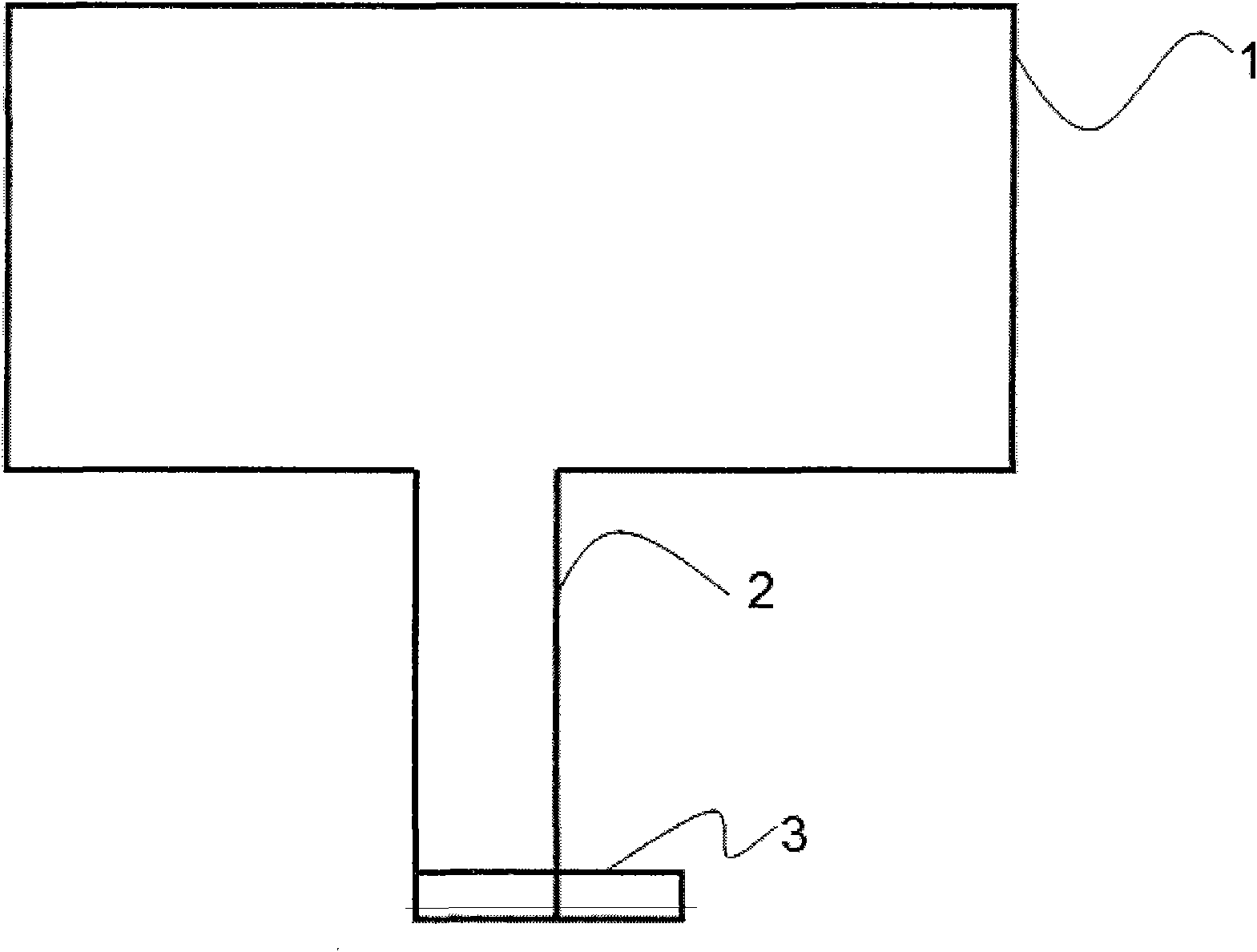

[0024] Such as figure 1 As shown, in the process of etching and cleaning the cavity of the PECVD equipment, the opening of the valve 3 on the exhaust pipe 2 remains unchanged, and the method of judging the completion of the etching and cleaning is determined by monitoring the change of the pressure in the cavity 1 .

[0025] In the etching process, the process parameters are as follows:

[0026] Oxygen flow: 1600sccm;

[0027] C 2 f 6 Flow: 1600sccm;

[0028] Valve opening: 17%;

[0029] During the etching process, when the pressure in the cavity changes from 3 torr to 2.5 torr, the etching cleaning is completed.

[0030] In this embodiment, a pressure gauge is used to monitor the change of the pressure in the cavity 1 .

[0031] After adopting this embodiment to judge that the etching is terminated, the test data are as follows:

[0032] Table 1

[0033] intracavity pressure

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com