Vibration power generator, vibration power generation device, and electronic device and communication device having vibration power generation device installed

A technology of generators and electrodes, applied in the direction of induction generators, etc., can solve problems such as complex structures and processes, and achieve the effects of improved reliability, stable output voltage, and reduced maintenance times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

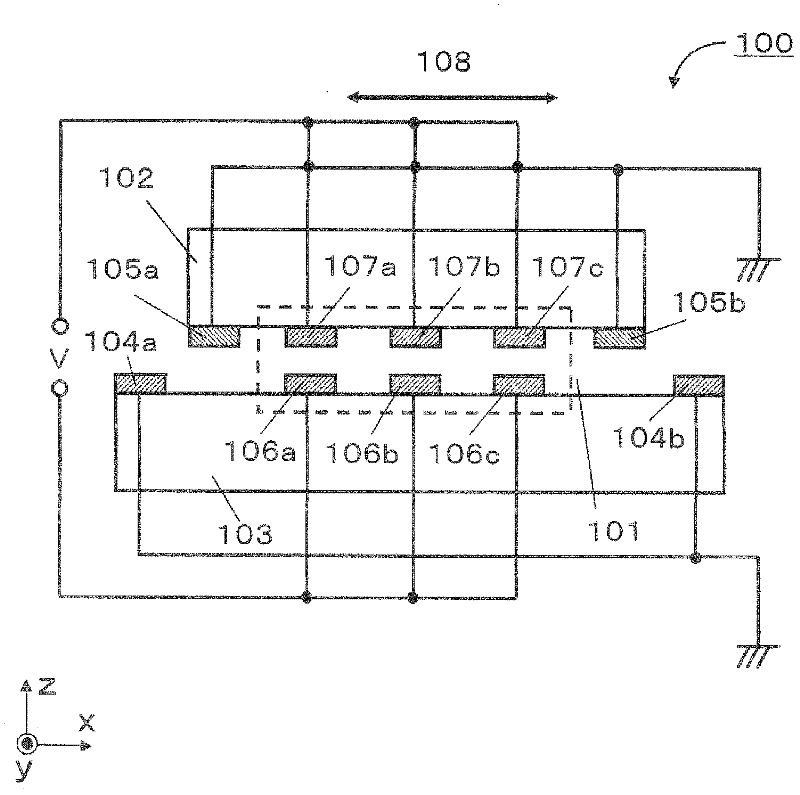

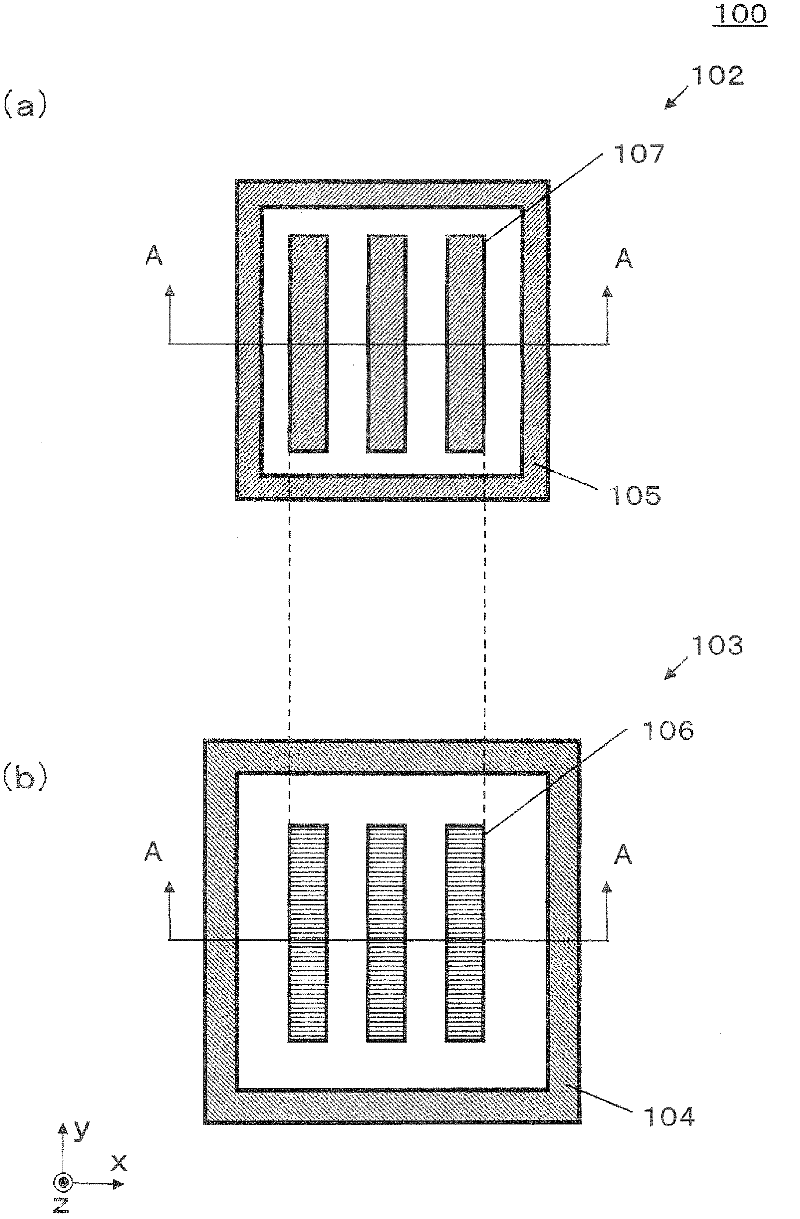

[0071] figure 1 is a cross-sectional view of the vibration power generator 100 according to Embodiment 1 of the present invention, figure 2 yes figure 1 The first substrate 102 of the vibration generator 100 ( figure 2 (a)), and the second substrate 103 ( figure 2 (b)) top view. figure 1 The section shown with the figure 2 The A-A cross-section is equivalent.

[0072] The vibration generator 100 is composed of a first substrate 102 and a second substrate 103 . On the first substrate 102 ( figure 1 Middle, lower side) are formed with first electrodes 107a, 107b, 107c. In addition, on the second substrate 103 ( figure 1 (middle, top) second electrodes 106a, 106b, 106c are formed at positions facing each of the first electrodes 107a, 107b, 107c.

[0073] Third electrodes 105 a and 105 b are further formed on the first substrate 102 , and fourth electrodes 104 a and 104 b are further formed on the second substrate 103 .

[0074] The first electrodes 107a, 107b, ...

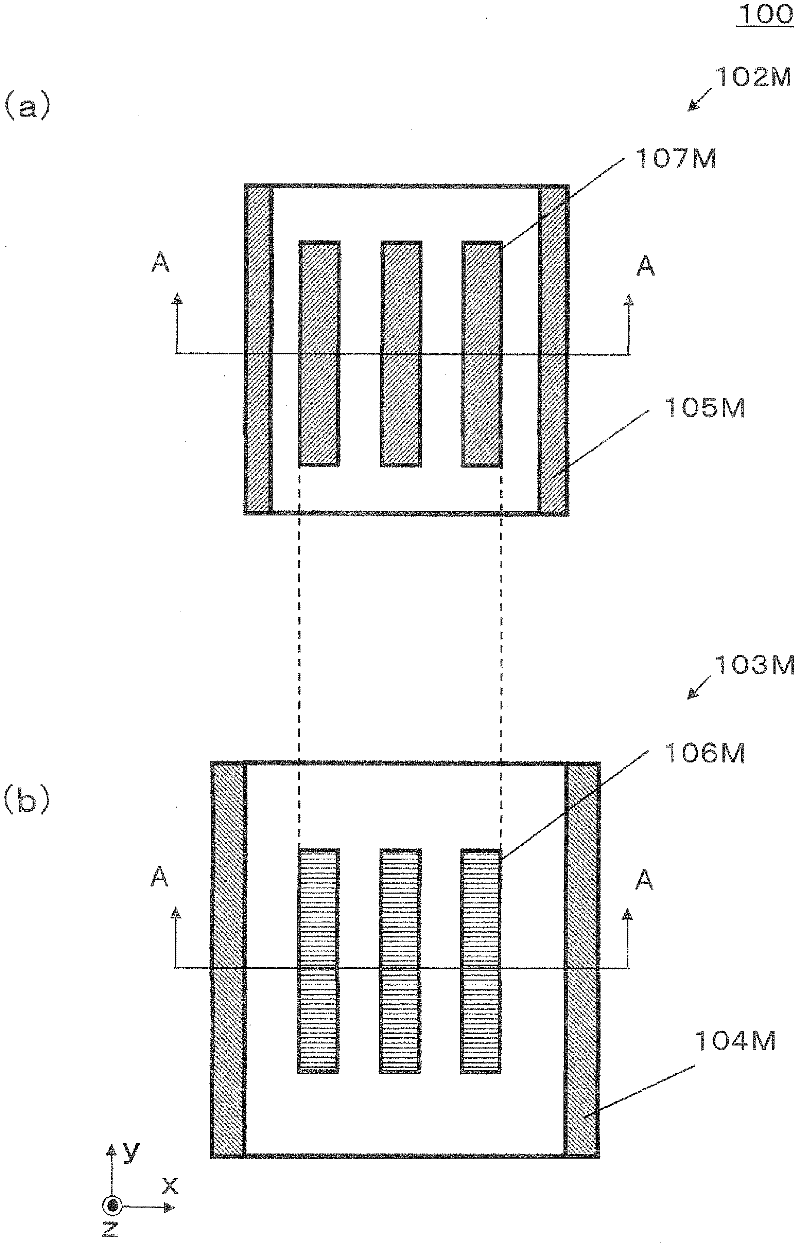

Embodiment approach 2

[0132] Figure 5 It is a cross-sectional view of vibration power generator 200 according to Embodiment 2 of the present invention. This differs from Embodiment 1 in that first protrusions 209 a and 209 b are formed between the first substrate 202 and the second substrate 203 .

[0133] Additionally, for Figure 5 Each shown member is given a number with a 200-series number in order to clarify that it is a member according to the present embodiment. Unless otherwise specified, each component is the same as the corresponding component in Embodiment 1 indicated by the same code except for the 100-digit numeral.

[0134] One end of the protrusions 209 a and 209 b is fixed to one of the first substrate 202 and the second substrate 203 , and the other end is not fixedly in contact with the other of the first substrate 202 and the second substrate 203 .

[0135] exist Figure 5 In the illustrated embodiment, one end (lower end) of the protrusions 209a, 2009b is fixed to the secon...

Embodiment approach 3

[0159] Image 6 is a cross-sectional view of the vibration power generator 300 in Embodiment 3 of the present invention ( Image 6 (a)) and the cross-sectional view of the first substrate 302 ( Image 6 (b)).

[0160] The difference from Embodiment 2 is that the vibration power generator 300 has a third substrate 310 disposed above the first substrate, and second protrusions 309 c and 309 d disposed between the third substrate 310 and the first substrate 302 .

[0161] Additionally, for Image 6 Each of the shown members is assigned a numeral with a 300 series number to clarify that it is a member according to the present embodiment. Unless otherwise specified, each component is the same as the corresponding component in Embodiments 1 and 2 indicated by the same code except for the 100-digit numeral.

[0162] In the present embodiment, the first protrusions 309a and 309b are provided with one end fixed to the second substrate 303 and the other end in contact with the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com