Method for making quick-frozen cooked lobsters and device used in method

A production method and technology of lobster, applied in the application, food preparation, food science and other directions, can solve the problem of unstable product quality, and achieve the effect of being suitable for long-distance transportation, stable product quality and long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

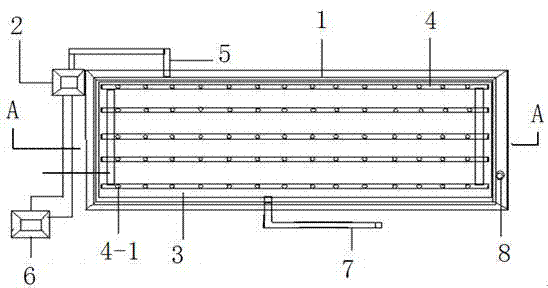

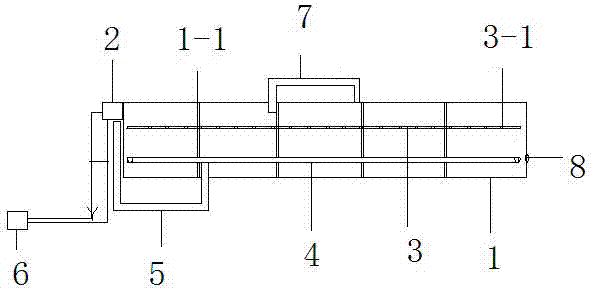

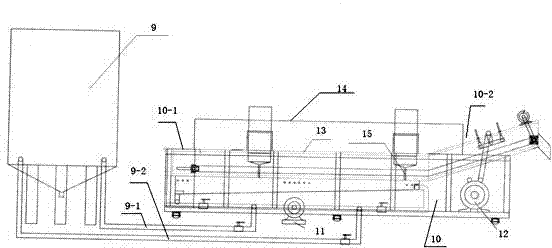

Image

Examples

Embodiment 1

[0023] Embodiment 1: the preparation method of the present invention also comprises the following steps after material selection:

[0024] Temporary cultivation and purification: Add a bubbling agent to the bubbling temporary cultivation tank and turn on the bubbling device to fully dissolve the bubbling agent; put the live lobster into the bubbling temporary cultivation tank, and keep the bubbling state for 40 minutes until the lobster is in a bubbling state. There is basically no dirt in the intestines. During this process, continuous inspection should be performed. If dead shrimp are found, they should be removed and stored in isolation.

[0025] Cleaning: Take out the temporarily purified lobster and put it into a bubble cleaning machine, and wash the lobster with running tap water for 2 minutes.

[0026] Drain: The cleaned lobster is transported to the conveyor chain, the surface water of the shrimp body is drained on the conveyor chain, and a special person is arranged t...

Embodiment 2

[0035] Embodiment 2: the preparation method of the present invention also comprises the following steps after material selection:

[0036] Temporary cultivation and purification: add a bubbling agent to the bubbling temporary cultivation tank and turn on the bubbling device to fully dissolve the bubbling agent; put the live lobster into the bubbling temporary cultivation tank, and keep the bubbling state for 30 minutes until the lobster is in a bubbling state. There is basically no dirt in the intestines. During this process, continuous inspection should be performed. If dead shrimp are found, they should be removed and stored in isolation.

[0037] Cleaning: Take out the temporarily purified lobster and put it into a bubble cleaning machine, and wash the lobster with running tap water for 2 minutes.

[0038] Drain: The cleaned lobster is transported to the conveyor chain, the surface water of the shrimp body is drained on the conveyor chain, and a special person is arranged t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com