Down-coat packing

A technology for fillers and down jackets, which is applied in the field of down jacket fillers to achieve the effects of avoiding drilling down, wide application range and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

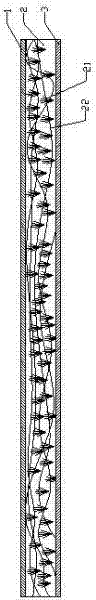

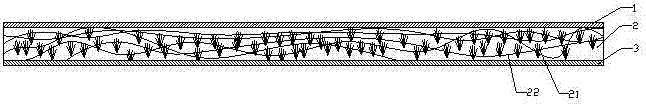

[0021] Such as figure 1 As shown, this embodiment includes a three-layer structure, the upper layer 1 and the lower layer 3 are non-woven fabrics, the middle layer 3 is a three-dimensional network structure formed by mixing and bonding down 21 and textile fibers 22, and the upper layer 1 and the lower layer 3 are connected with the middle layer. bonded into a whole. Among them, the textile fiber 22 is preferably a three-dimensional crimped hollow polyester fiber treated with silicone oil. The characteristics of this fiber are soft and lubricated, the fibers are not entangled with each other, and the bulkiness is good. Therefore, the finished pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com