Magnetic-disc-adsorptive wall climbing robot

A wall-climbing robot and adsorption-type technology, applied in the field of robots, can solve the problems that the magnetic adsorption force cannot be changed, and can not solve the contradiction between wall adsorption and mobile operation, and achieve the effect of compact structure, concise and clean appearance, and flexible movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

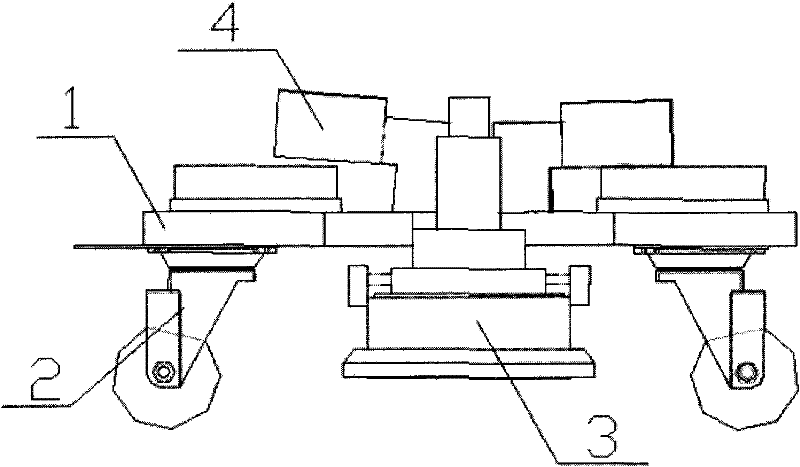

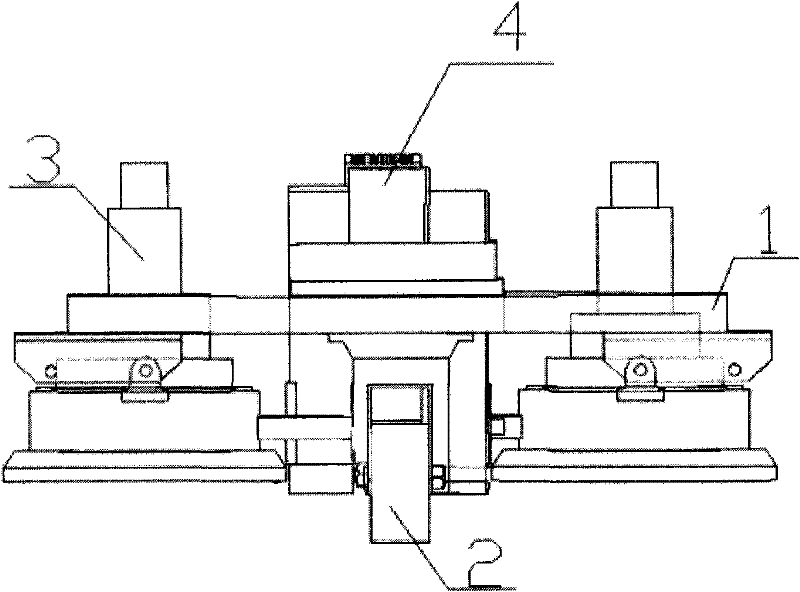

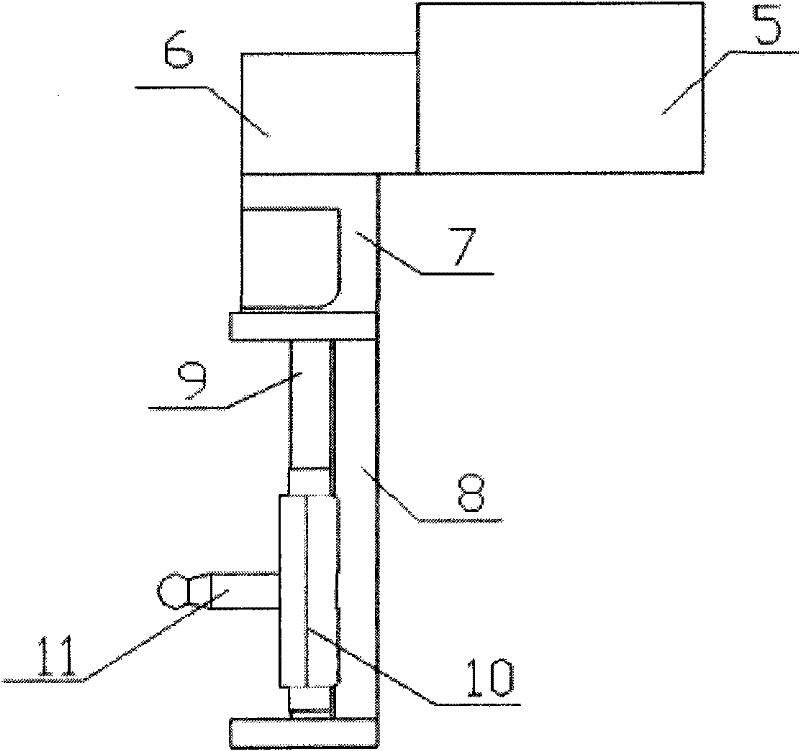

[0019] The specific implementation manners of the present invention will be described in further detail below with reference to the accompanying drawings. Those of ordinary skill in the art should understand that the following examples are only schematic illustrations of the technical solutions of the present invention, and preferably introduce the specific implementation of the present invention and the operation process of the wall-climbing robot of the present invention, but the present invention does not It's not just limited to this.

[0020] As mentioned above, according to the adsorption function, wall-climbing robots roughly include vacuum adsorption and disk adsorption. The vacuum adsorption method is driven by a cylinder. Whether it is a single suction cup structure or a multi-suction cup structure, it is not limited by the wall material. However, when the wall surface is uneven, the vacuum adsorption wall-climbing robot is likely to cause air leakage from the suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com