Overheat protecting device and method of motorized spindle and cutter

A technology of overheat protection and electric spindle, which is applied to the overheat protection device of electric spindle and the field of cutting machine, which can solve the problems of not fully considering the overheat protection of the electric spindle of the cutting machine, so as to avoid the influence of the main engine's working accuracy, stabilize the working state, and improve the work efficiency. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

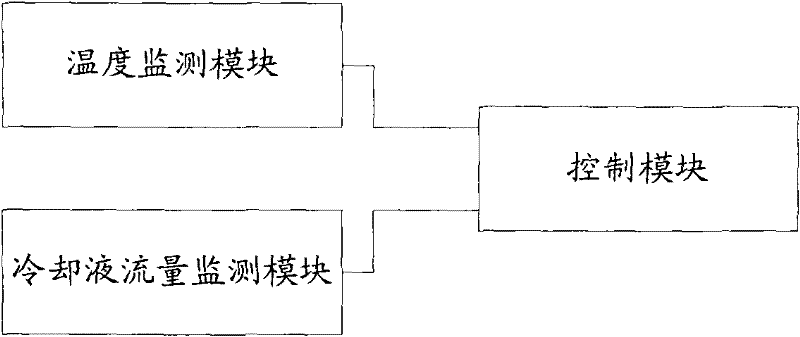

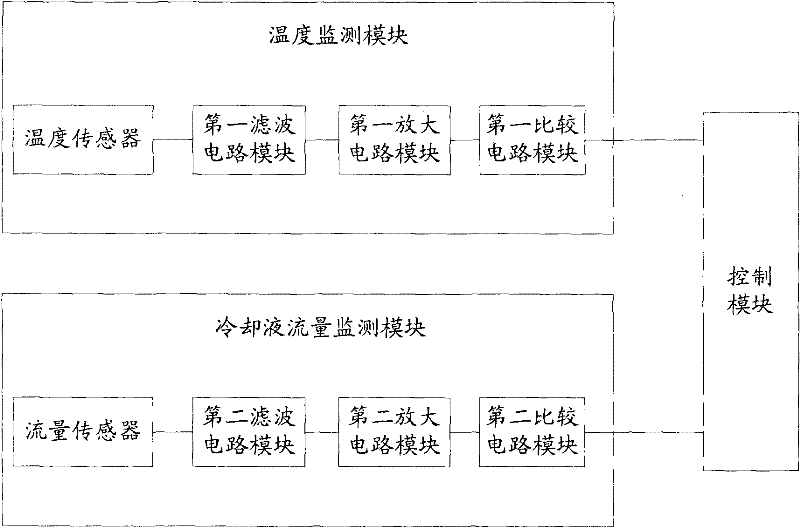

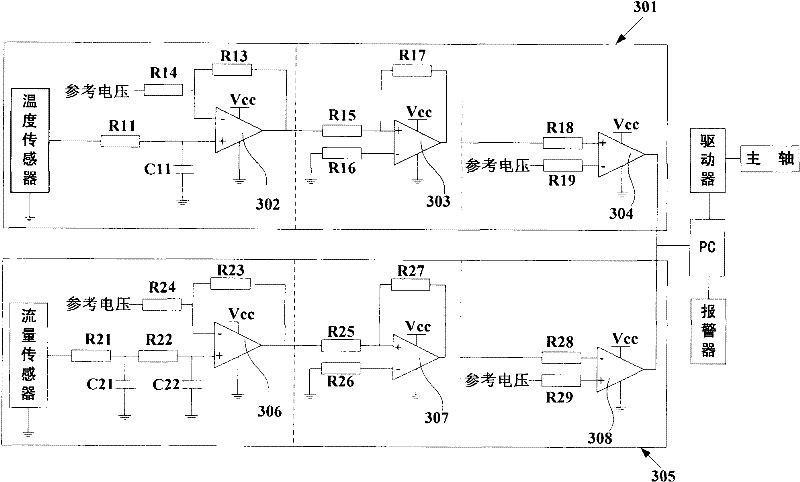

[0051] figure 1 It is a structural schematic diagram of the overheat protection device of the electric spindle according to the embodiment of the present invention. Such as figure 1 , the overheating protection device of the electric spindle according to one embodiment of the present invention includes: a temperature monitoring module for monitoring the temperature of the electric spindle and outputting a first signal; a cooling liquid flow monitoring module for monitoring the flow of cooling liquid such as cooling water, And output a second signal, the coolant is used to cool the electric spindle; the control module is used for when the first signal indicates that the temperature of the electric spindle is higher than a predetermined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com