Novel side wall cross beam structure

A beam, a new type of technology, applied in the field of plate cold stamping, can solve the problems of rising material consumption costs, large size, large blanks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

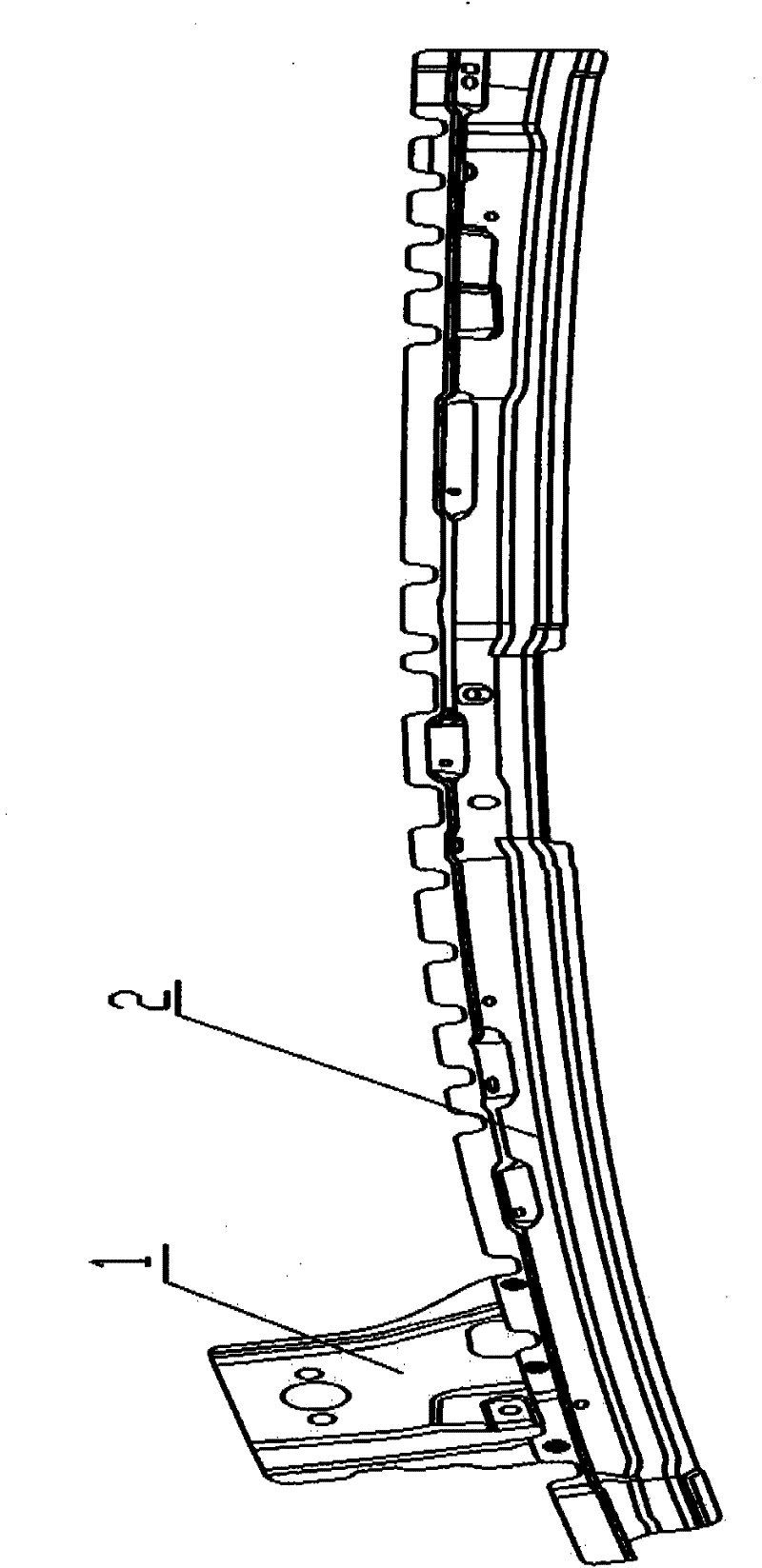

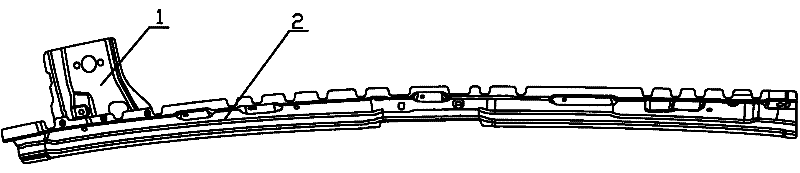

[0008] It can be seen from the accompanying drawings that the novel side beam structure includes mounting holes on the side beam, and its feature is that the side beam is welded by two sub-parts 1 and 2. The specific is: after the processing of part 1 and part 2 respectively, the two parts are welded together, so that the blanks of part 1 and part 2 can be selected respectively, and the consumption of blanks can be significantly reduced to reduce the cost the goal of. The present invention will cover the scope described in the technical solution, as well as various modifications and equivalent changes in the scope of the claims, without departing from the technical solution of the present invention, any modification that can be easily realized by those skilled in the art made to the present invention Or improvements all belong to the scope of protection claimed by the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com