Band-shaped body connection structure

A belt-shaped body and structure technology, which is applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., to achieve the effect of keeping the conveying interval constant, simple structure, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

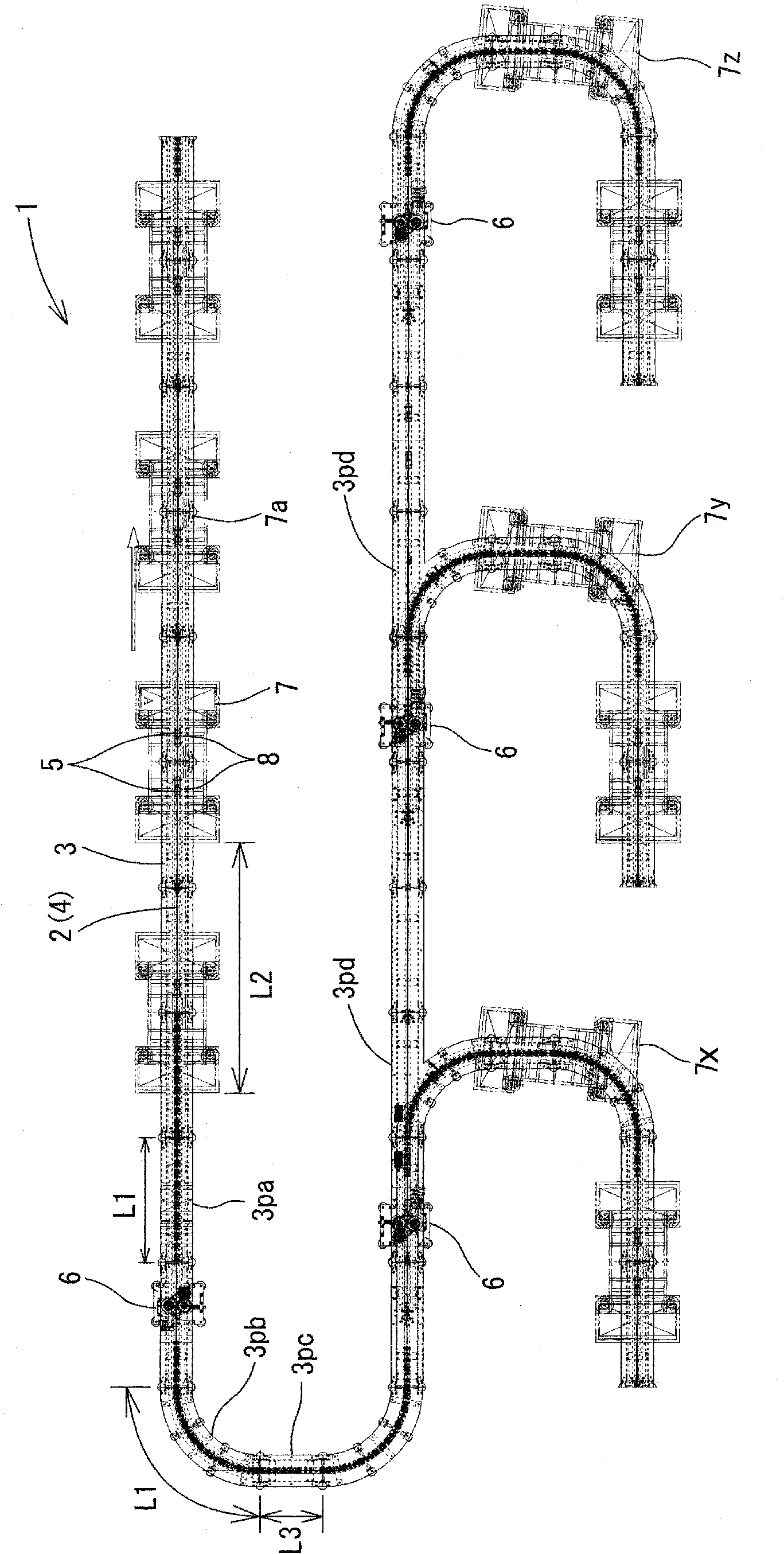

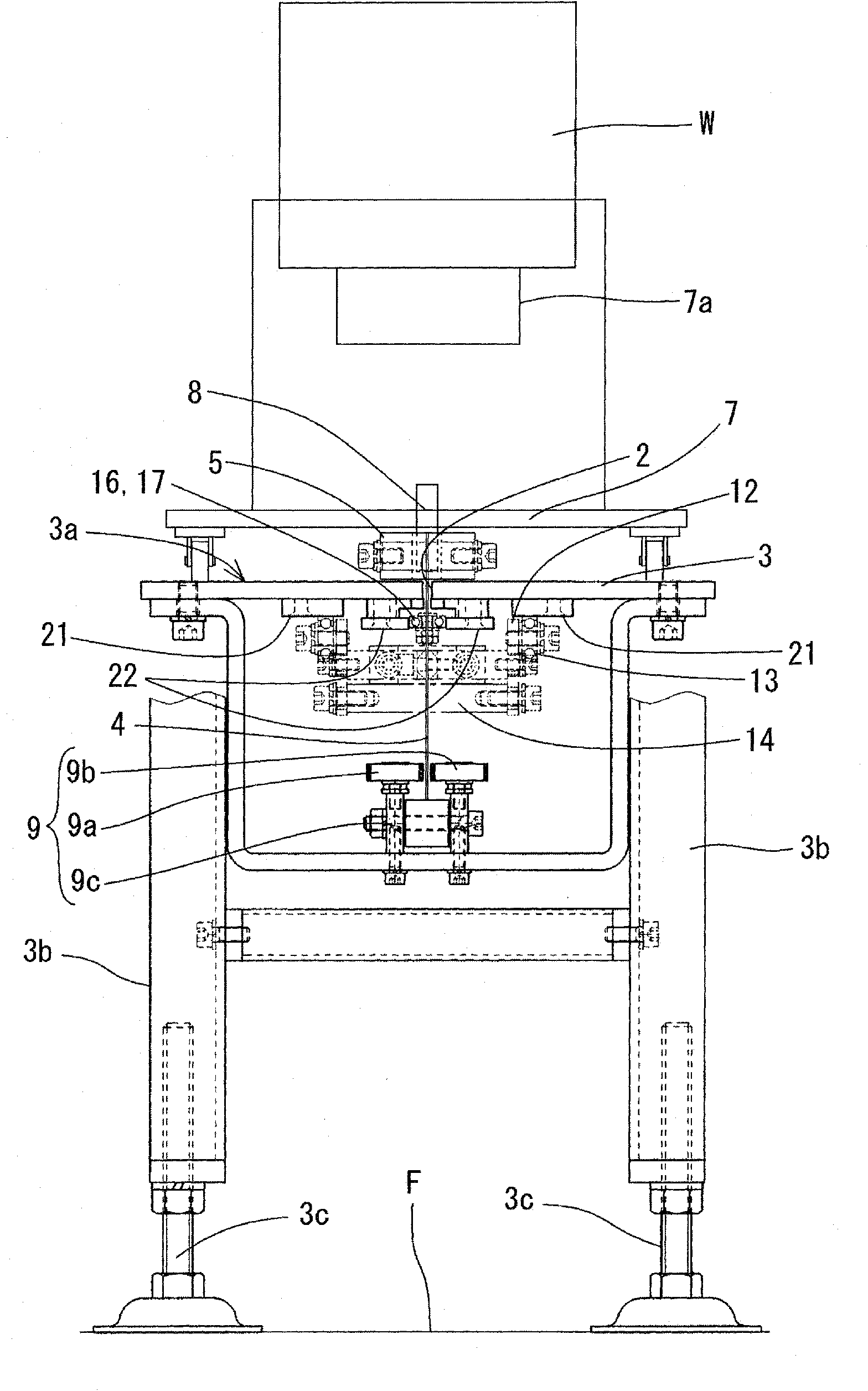

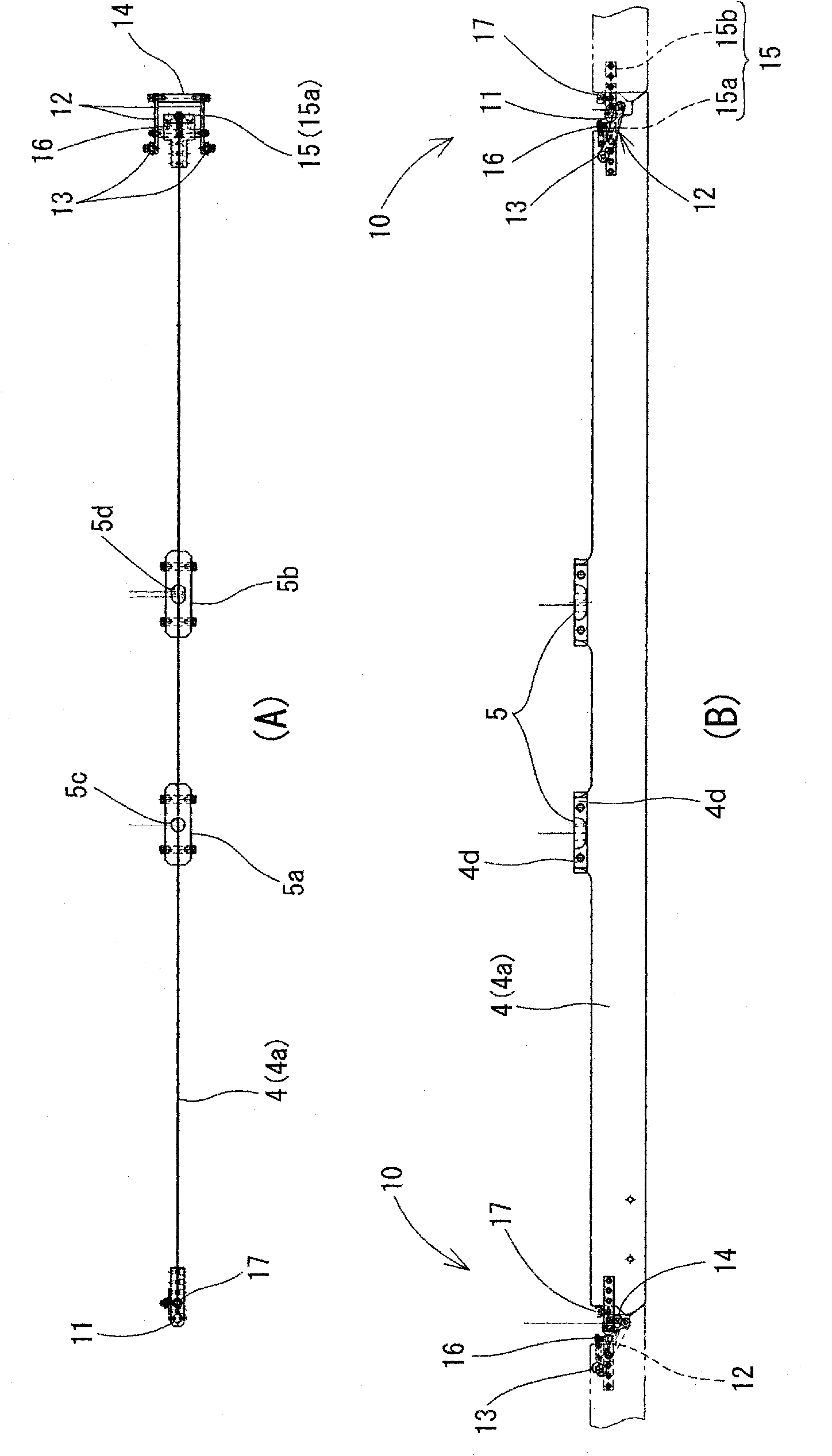

[0030] Below, use Figure 1~Figure 9 The structure of the belt-shaped body connection structure 10 of the present invention will be described. The connecting structure 10 of the belt-shaped body of the present invention constitutes a part of the workpiece conveying device 1. The workpiece conveying device 1 has: a stand 3 formed with a cutout 2; a belt-shaped body 4 whose upper part is housed in the stand 3 in a manner guided by the cutout 2 of the stand 3; The upper end of the belt-shaped body 4 is connected and protrudes from the upper part of the platform 3; the driving part 6, which provides the power to move the belt-shaped body 4 along the incision 2 in the conveying direction; and the assembly trolley 7, which has a support As an example of the work W, a support portion 7 a of an engine or an engine assembly and a connecting portion 8 connected to the trolley connecting portion 5, and the assembly trolley 7 travels on the platform 3.

[0031] The workpiece conveying devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com