Resonance drive type piezoelectric pump

A piezoelectric pump and driven technology, which is applied in the direction of pumps, pump components, machines/engines, etc., can solve the problems of large fluid flow damping, difficult heat, slow valve movement, etc., to achieve amplification and alternating deformation, good heat dissipation, Effect of high output flow and output pressure performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structure and principle of the present invention will be further described in the following embodiments in conjunction with the accompanying drawings.

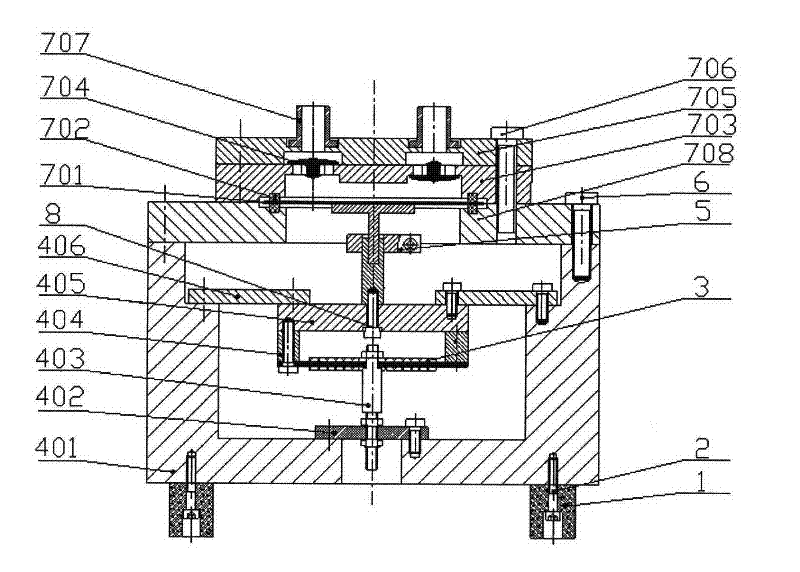

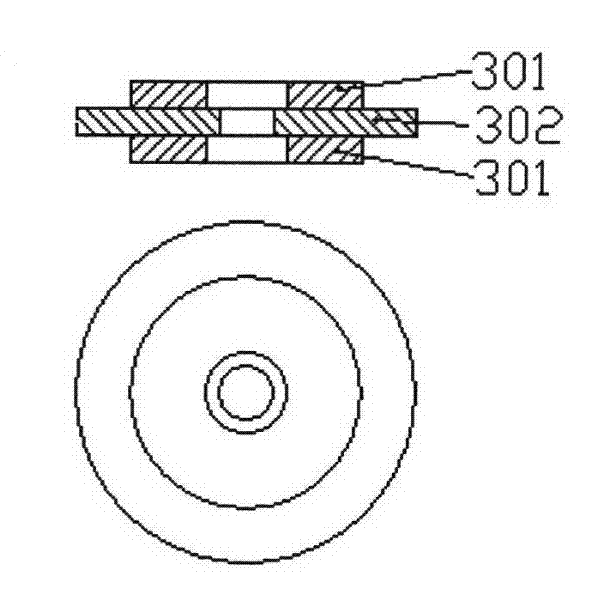

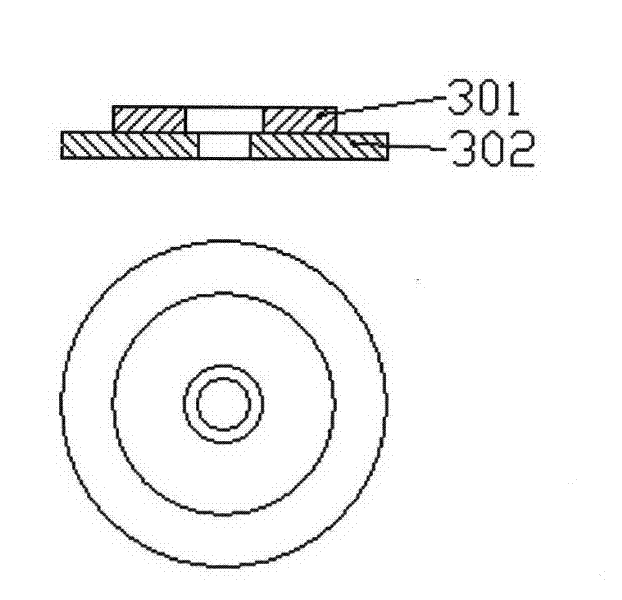

[0018] refer to figure 1 , the piezoelectric pump of the present invention consists of a piezoelectric vibrator 3 that converts electrical energy into mechanical energy as a driving force source, and forms a resonance system together with a resonance amplification mechanism 4, a vibration transmission mechanism 5, a fluid driving mechanism 7, and a driven fluid. The base 401 is supported on the ground by four shock absorbing blocks 1 . The piezoelectric vibrator 3 is connected with the resonant amplifying mechanism 4, and the specific connection method is as follows: in the lower part, the piezoelectric vibrator is connected to the base 401 through the vibration transmission rod 403 and the elastic adjustment piece 402; in the upper part, the piezoelectric vibrator is connected through the connecting ring 404, The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com