Flow collecting valve and crane hydraulic control system with the same

A technology of confluence valve and control oil port, which is applied in the field of crane hydraulic control system and confluence valve, can solve the problems of not effectively reducing energy loss, the pressure does not reach the overflow valve, and the pressure is small, so as to reduce energy consumption. , to ensure the effect of energy consumption and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

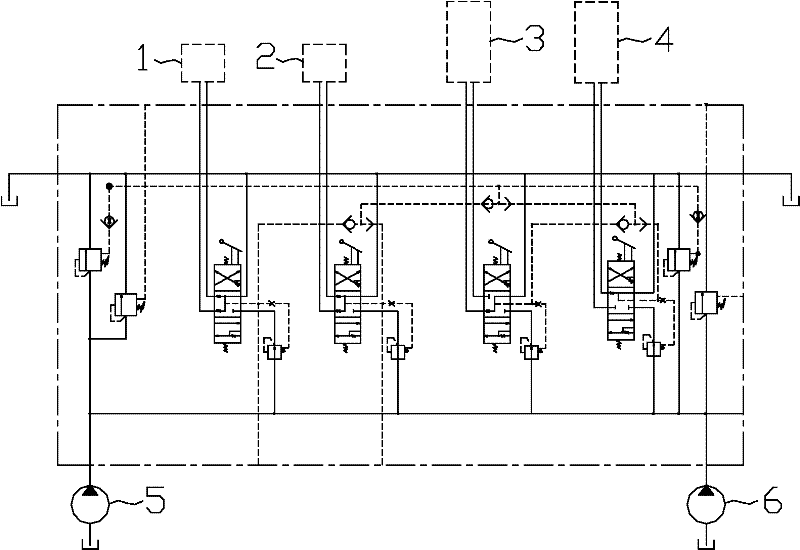

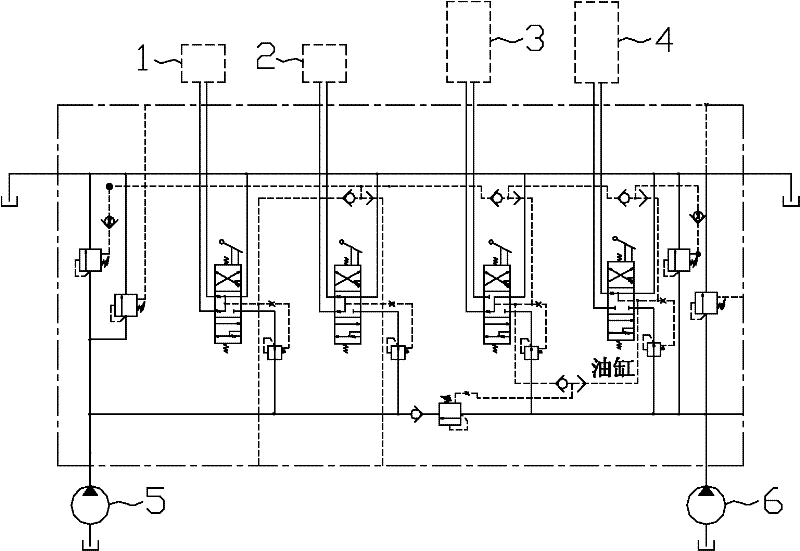

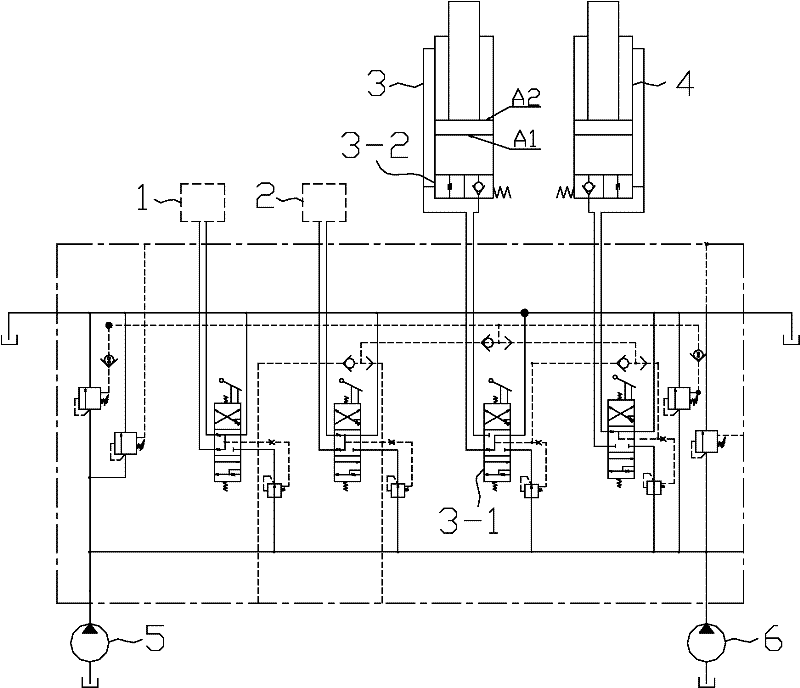

[0047] The core of the present invention is to provide a confluence valve. The merging valve can ensure that the telescopic oil cylinder and the luffing oil cylinder of the crane have both high extension efficiency and low retraction energy consumption.

[0048] Another core of the present invention is to provide a crane hydraulic control system provided with the confluence valve.

[0049] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0050] In this article, terms such as "up, down, left, right" indicating orientation are based on the positional relationship of the drawings, and should not be interpreted as an absolute limitation on the scope of protection. Similarly, terms such as "first, second" It is only for the convenience of description to distinguish different components with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com