Excavator operation tool confluence control system and excavator

A work tool and control system technology, applied in the field of hydraulic excavators, can solve the problems of inability to improve the work efficiency of the whole machine, waste of hydraulic oil energy, etc., and achieve the effect of improving work efficiency and energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

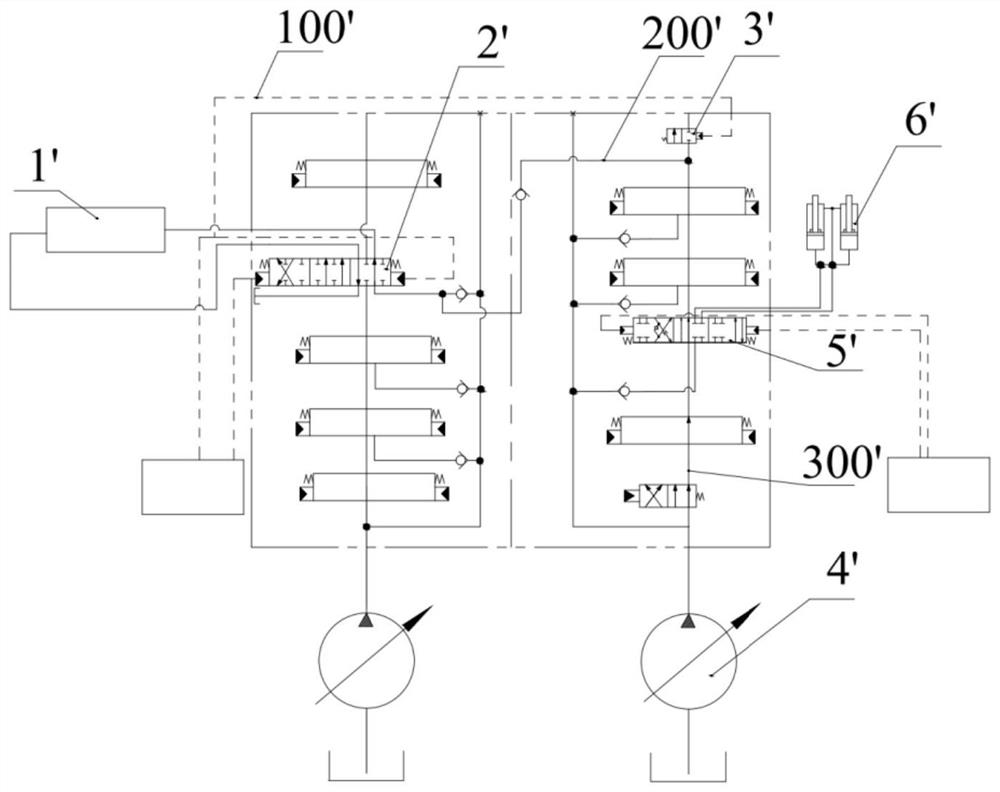

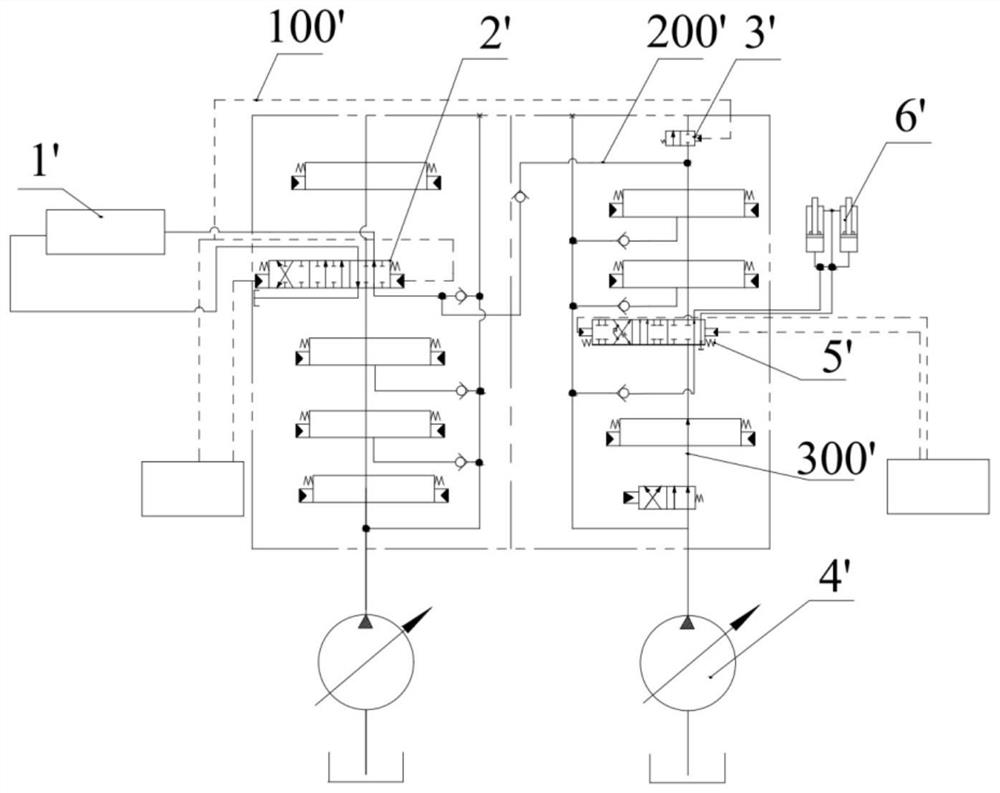

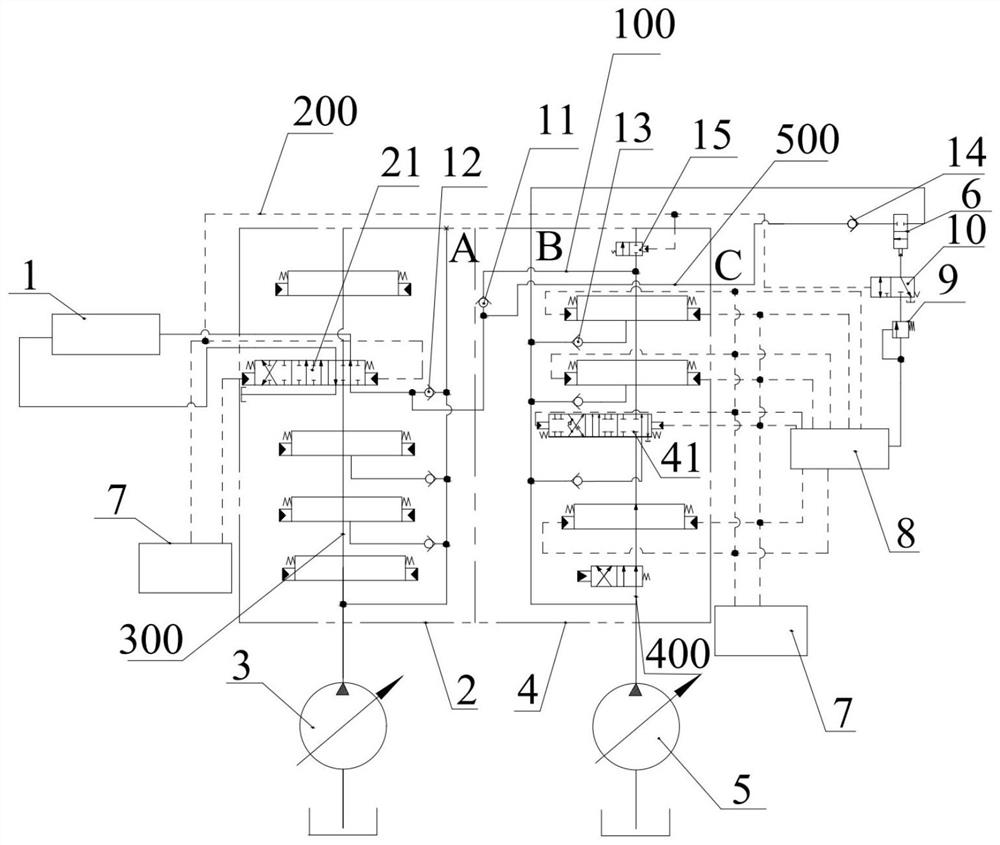

[0048] Such as Figure 3 ~ Figure 5 As shown, the present embodiment provides an excavator work tool confluence control system, the excavator work tool confluence control system includes a work tool driver, a first valve group 2, a first hydraulic pump 3, a second valve group 4, The second hydraulic pump 5 , the confluence oil circuit 100 and the second reversing valve 6 . The working tool 1 can be a bucket, a breaker, a hydraulic shear, a hydraulic pliers, or a grab bucket, so as to perform excavation, crushing, shearing, pinching, or grabbing. The working tool driving part is drivingly connected with the working tool 1, and the working tool driving part drives the working tool 1 to act. The first valve group 2 includes a first reversing valve 21, and the first reversing valve 21 communicates with the driving member of the working tool; the first hydraulic pump 3 communicates with the first reversing valve 21, and is configured to be able to pass through the first reversing ...

example 1

[0063] In this example, one of the multiple reversing valves in the second valve group 4 is the boom reversing valve 41, the boom cylinder 16 is drivingly connected to the boom, and the boom reversing valve 41 communicates with the boom cylinder 16 , the oil outlet of the second reversing valve 6 is directly connected with the oil port C, the oil inlet of the second reversing valve 6 is connected with the oil port B, and the oil port A is blocked; the shuttle valve group 8 includes the boom shuttle valve 81 , two ends of the boom shuttle valve 81 are connected to the pilot oil circuit at both ends of the boom reversing valve 41 , and the other end is connected to the sequence valve 9 .

[0064] Such as image 3 and Figure 4 As shown, when the excavator is in the merged working mode, and the boom and the working tool 1 work at the same time, the hydraulic oil in the second hydraulic pump 5 is divided into two paths, and one path enters the boom cylinder 16 through the boom reve...

example 2

[0067] In this example, one of the multiple reversing valves in the second valve group 4 is the boom reversing valve 41, the boom cylinder 16 is drivingly connected to the boom, and the boom reversing valve 41 communicates with the boom cylinder 16 , the oil outlet of the second reversing valve 6 is directly connected with the oil port A, the oil inlet of the second reversing valve 6 is connected with the oil port B, and the oil port C is blocked; the shuttle valve group 8 includes a boom shuttle valve 81 , two ends of the boom shuttle valve 81 are connected to the pilot oil circuit at both ends of the boom reversing valve 41 , and the other end is connected to the sequence valve 9 .

[0068] Such as image 3 and Figure 5 As shown, when the excavator is in the confluence mode, and the boom and the work tool 1 work at the same time, the hydraulic oil in the second hydraulic pump 5 is divided into two paths, and one path enters the boom cylinder 16 through the boom reversing v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com