Endoscope technology-based discharge-trace inspection system

A technology for discharge traces and inspection systems, which can be used in CCTV systems, fault locations, etc., to solve problems such as omissions, wasted time, and long distances in inspection work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

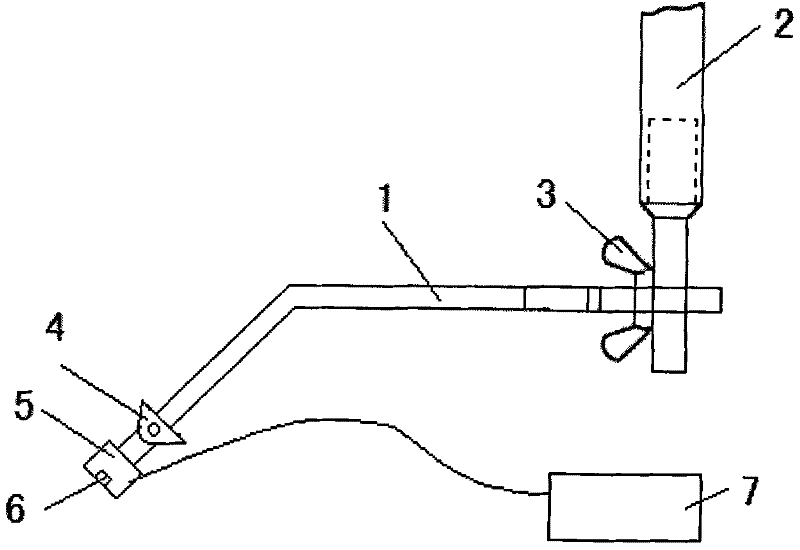

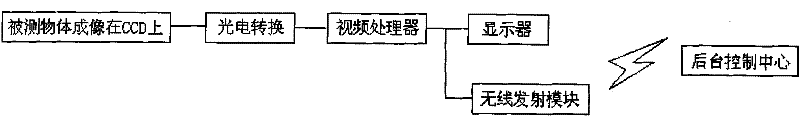

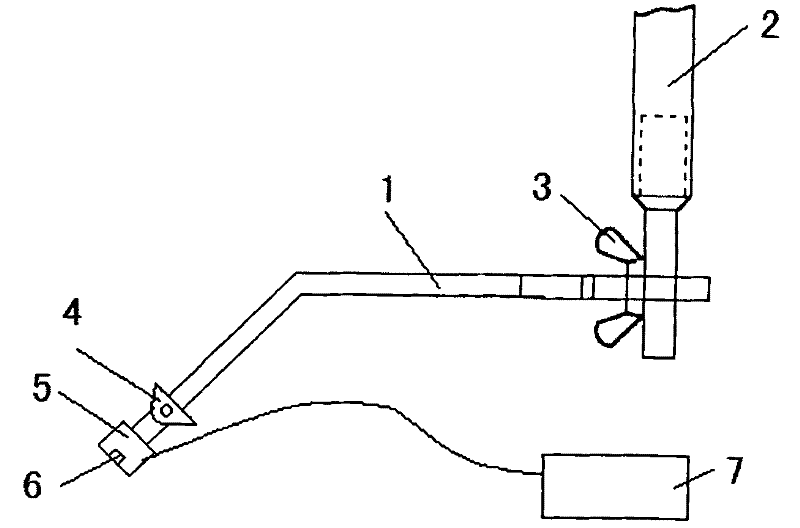

[0015] Such as figure 1 As shown, the present invention comprises a detection frame main body 1, one end of the detection frame main body 1 is connected with an insulating operating rod 2, the other end of the detection frame main body 1 is connected with a universal joint 4, and the front end of the universal joint 4 is fixed with a CCD coupling cavity mirror 5 and An intracavity cold light illumination system 6, wherein the intracavity cold light illumination system 6 is located in the CCD coupling cavity mirror 5; the above-mentioned CCD coupling cavity mirror 5 is connected to the smart terminal 7.

[0016] It should be noted that the above-mentioned detection frame main body 1 and the insulating operating rod 2 are connected through an adjusting nut 3 , so that the positional relationship between the detecting frame main body 1 and the insulating operating rod 2 can be adjusted. The above-mentioned detection frame main body 1 is a support rod with an angle of 135° in the ...

Embodiment 2

[0022] The difference between this embodiment and Embodiment 1 is that in this embodiment, the smart terminal 7 further includes a wireless transmitting module, and the wireless transmitting module is connected to the background control center. Correspondingly, the background control center should have a wireless receiving module to receive the picture information sent by the smart terminal 7. The above wireless module can use the 3G network, or a KYL-320M wireless communication module.

[0023] When the intelligent terminal is connected to the background control center by wireless means, it can also facilitate other monitoring personnel to see information in time. In this way, the monitoring personnel in the background can help the actual operating staff to perform detection, so as to prevent the actual operating staff from missing detection.

[0024] Other technical characteristics are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com