Disc checking device and disc checking method

An inspection device and re-inspection technology, applied in the direction of digital signal error detection/correction, digital recording/reproduction, etc., can solve the problem of low reliability of inspection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

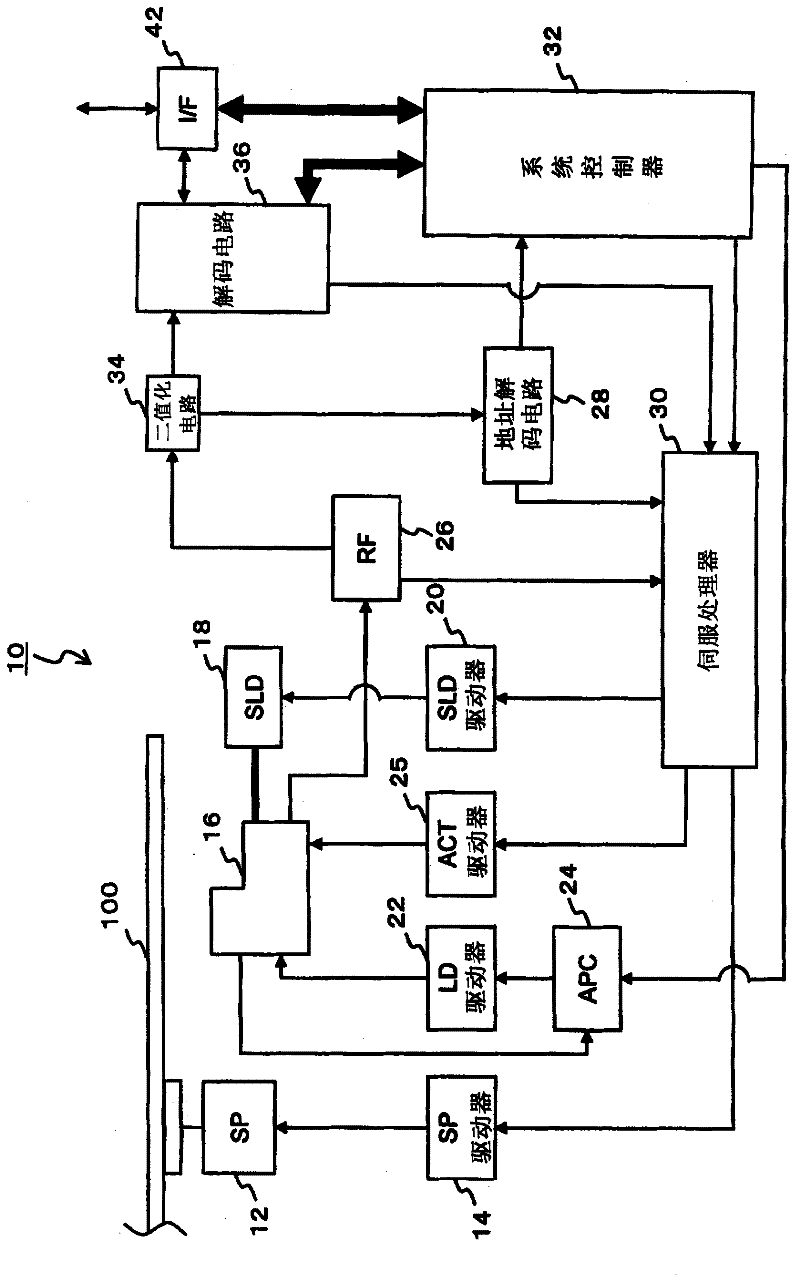

[0026] Embodiments of the present invention will be described below with reference to the drawings. figure 1 It is a block diagram showing the configuration of the disc inspection device 10 according to the embodiment of the present invention. This disk inspection apparatus 10 is an apparatus for inspecting whether there is a problem (defect) that makes it difficult to reproduce the disk 100 (for example, DVD, CD, Blu-ray disk, etc.) as a recording medium. The disc inspection device 10 will be described in detail below.

[0027] A disk 100 such as a CD or a DVD to be inspected is driven to rotate by a spindle motor (SP) 12 . The spindle motor 12 is driven by an SP driver 14, and the SP driver 14 is servo-controlled by a servo processor 30 so as to have a desired rotation speed. At this time, the servo processor 30 may rotate the disk 100 at a constant angular velocity or at a constant linear velocity in accordance with an instruction from the system controller 32 .

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com