Nonaqueous secondary battery and nonaqueous secondary battery pack

A secondary battery, non-aqueous technology, used in secondary batteries, large-sized batteries/battery packs, small-sized batteries/battery packs, etc., can solve the problems of difficulty in reducing battery voltage and increasing short-circuit current. The effect of suppressing thermal runaway, suppressing smoking or cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0043] [making of positive electrode]

[0044] The positive electrodes commonly used in the respective Examples and Comparative Examples were produced as follows. Lithium cobalt oxide (LiCoO 2 ), activated carbon HS-100 (manufactured by Denkai Kogyo Co., Ltd.) Wherein, N-methylpyrrolidone (NMP) was added in such a manner as to reach 50 mass % of the mass of the positive electrode mixture to prepare a positive electrode active material mixture slurry. Then, the positive electrode active material mixture slurry is coated on both sides of the positive electrode core made of aluminum foil with a thickness of 13 μm by the doctor blade method (coating amount: 400g / m 2 ), and then heated and dried (70-140° C.) to remove NMP, and then press-molded (packing density: 3.70 g / cc) to produce a positive electrode.

[0045] [Production of Negative Electrode]

[0046] The negative electrodes commonly used in the respective Examples and Comparative Examples were produced as follows. Artif...

experiment example 2

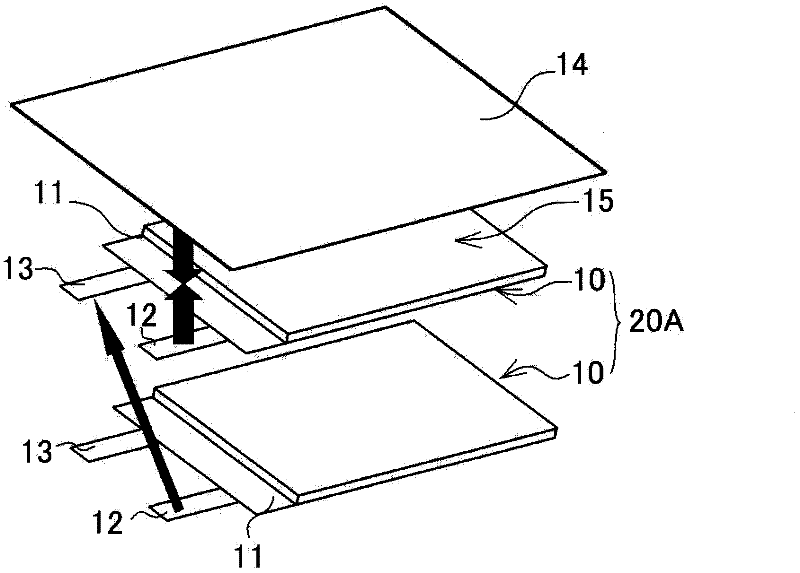

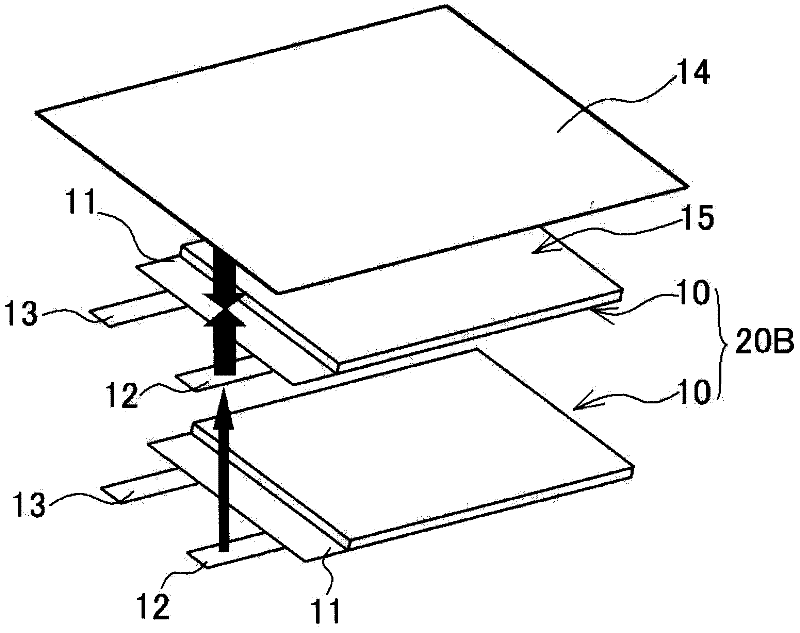

[0080] Next, for the battery modules of Examples 13 to 16 and Comparative Examples 23 to 26 obtained as follows, the nailing characteristics were measured in the same manner as in Experimental Example 1 above, and the results are shown in Table 3. Stack two batteries produced in parallel in series or in parallel, constitute the obtained material as a battery module, and then contact the flat part of the non-aqueous secondary battery using the laminated outer package in a state covered in parallel. , an aluminum plate with a thickness of 0.5 mm was arranged, and the aluminum plate was ultrasonically welded to the positive lead tab of one battery module.

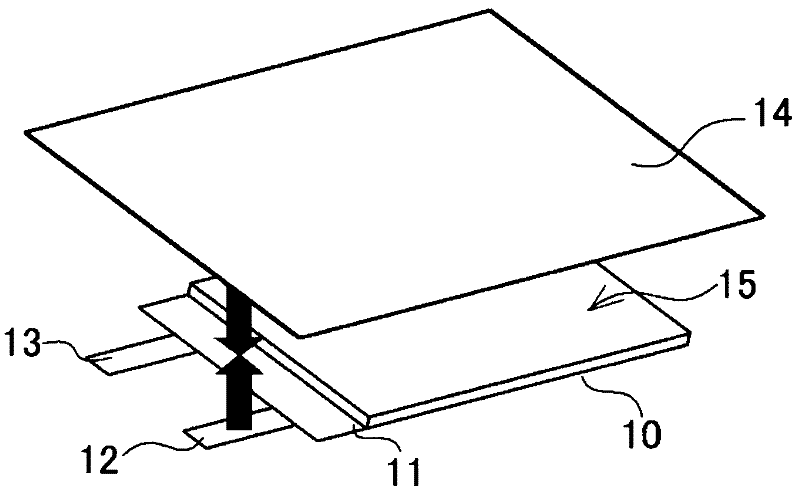

[0081] For Experimental Example 2, an exploded perspective view of a non-aqueous secondary battery assembly 20A obtained by connecting two non-aqueous secondary batteries using a laminated outer package in series is shown in figure 2 In , an exploded perspective view of a nonaqueous secondary battery assembly 20B obtained by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com