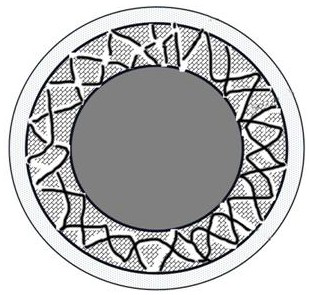

A double-coated lithium battery positive electrode material and preparation method thereof

A positive electrode material, lithium battery technology, applied in the direction of battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of inability to protect the material surface for a long time, unsatisfactory safety performance, hindering lithium ion deintercalation, etc., to achieve heat suppression Occurrence of runaway, enhanced force, effect of thin coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing a double-coated lithium battery positive electrode material, comprising the steps of:

[0033] 1) Mix the high-nickel precursor and the lithium source, and perform the first roasting, and the roasted product is crushed, washed, filtered, dried, sieved, and demagnetized to obtain the high-nickel material A; the lithium source is hydrogen One or both of lithium oxide and lithium carbonate;

[0034] 2) Mix the high-nickel material A, lithium salt, pore-forming agent and inorganic dispersant uniformly to obtain mixture B, wherein, in terms of mass ratio, high-nickel material A, lithium salt, pore-forming agent=100:(0.1~2 ): (0.1~0.4), mixture B is roasted for the second time to obtain mixture C; the roasting temperature is 100~250°C, and the roasting time is 30~60min;

[0035] 3) The adhesive is configured into a 1-5% adhesive solution, the mixture C is put into the adhesive solution, stirred for 0.5-1 hour, and then the mixture is filtered, dried, a...

Embodiment 1

[0054] Prepare a double-coated lithium battery positive electrode material, comprising the steps of:

[0055] 1) Weigh 452g lithium hydroxide monohydrate, 950g high-nickel ternary cathode material large particle precursor [Ni 90 co 06 mn 04 ](OH) 2 , put the material into a sagger, place it in a kiln for sintering with oxygen at 750°C for 15 hours, and after cooling, crush, wash, filter, dry, sieve, and demagnetize to obtain a high-nickel material A;

[0056] 2) Evenly disperse 1000g of high-nickel material A, 50g of lithium borate, and 4g of polyethylene glycol in deionized water. The mixture is fully mixed with a high-speed mixer to obtain mixture B. Filter and dry mixture B and put it into a sagger. Place in a kiln at 200°C and sinter for 1 hour under a nitrogen atmosphere to obtain mixture C;

[0057] 3) Configure a hydroxypropyl cellulose solution with a mass concentration of 3%, put the mixture C into the hydroxypropyl cellulose solution, stir for 1 hour, filter the ...

Embodiment 2

[0062] 1) Weigh 452g lithium carbonate, 950g high-nickel ternary cathode material large particle precursor [Ni 90 co 06 mn 04 ](OH) 2 , put the material into a sagger, place it in a kiln for sintering with oxygen at 750°C for 13 hours, and after cooling, crush, wash, filter, dry, sieve, and demagnetize to obtain a high-nickel material A;

[0063] 2) Evenly disperse 1000g of high-nickel material A, 45g of lithium lanthanum zirconium oxide, and 4g of ammonium bicarbonate in deionized water. The mixture is fully mixed with a high-speed mixer to obtain mixture B. After filtering and drying, put mixture B into a sagger, Place in a kiln at 150°C and sinter for 0.5h under nitrogen atmosphere to obtain mixture C;

[0064] 3) Prepare a hypromellose solution with a mass concentration of 4%, put the mixture C into the hypromellose, stir for 1 hour, filter the mixture, dry it, put it into a sagger, place it in a kiln at 500°C, Sintering under nitrogen atmosphere for 2h to obtain mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com