Non-aqueous lithium storage device

A technology for electric storage components and non-aqueous electrolytes, which can be applied to lithium batteries, electrical components, non-aqueous electrolyte batteries, etc., and can solve problems such as the safety risks of electric storage components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

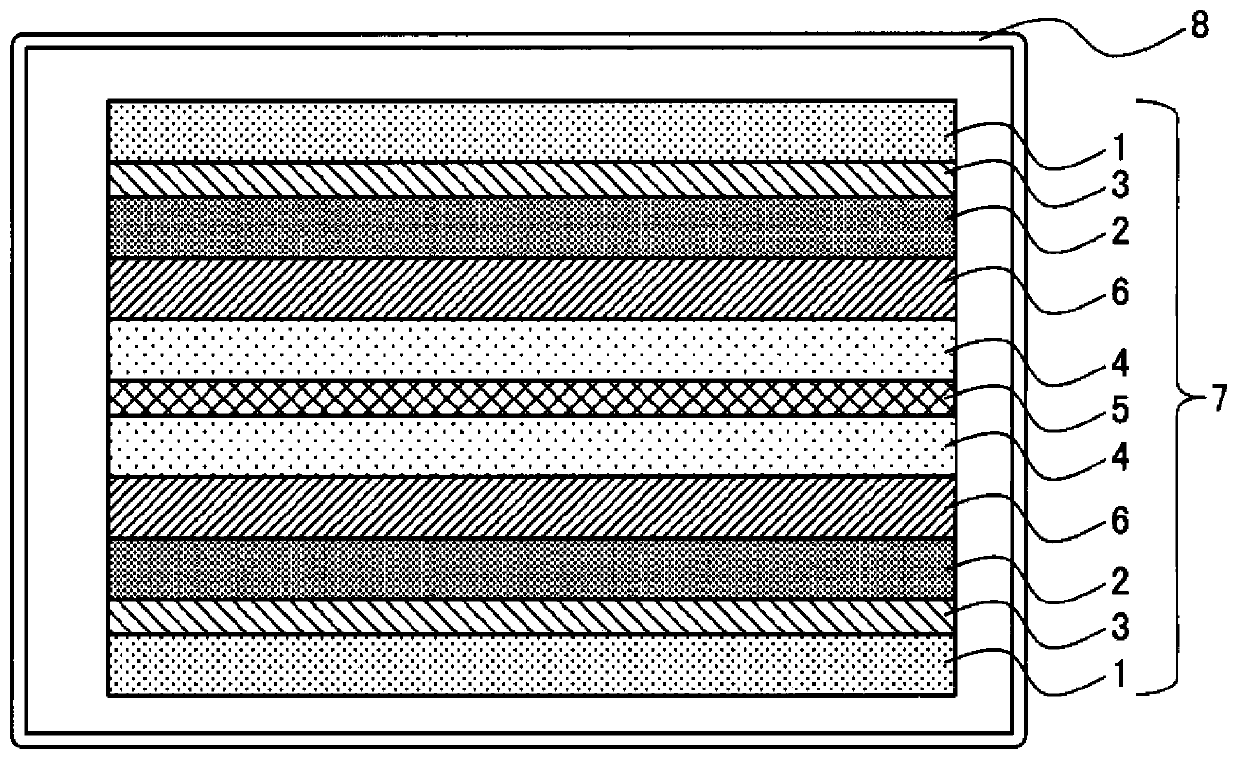

Image

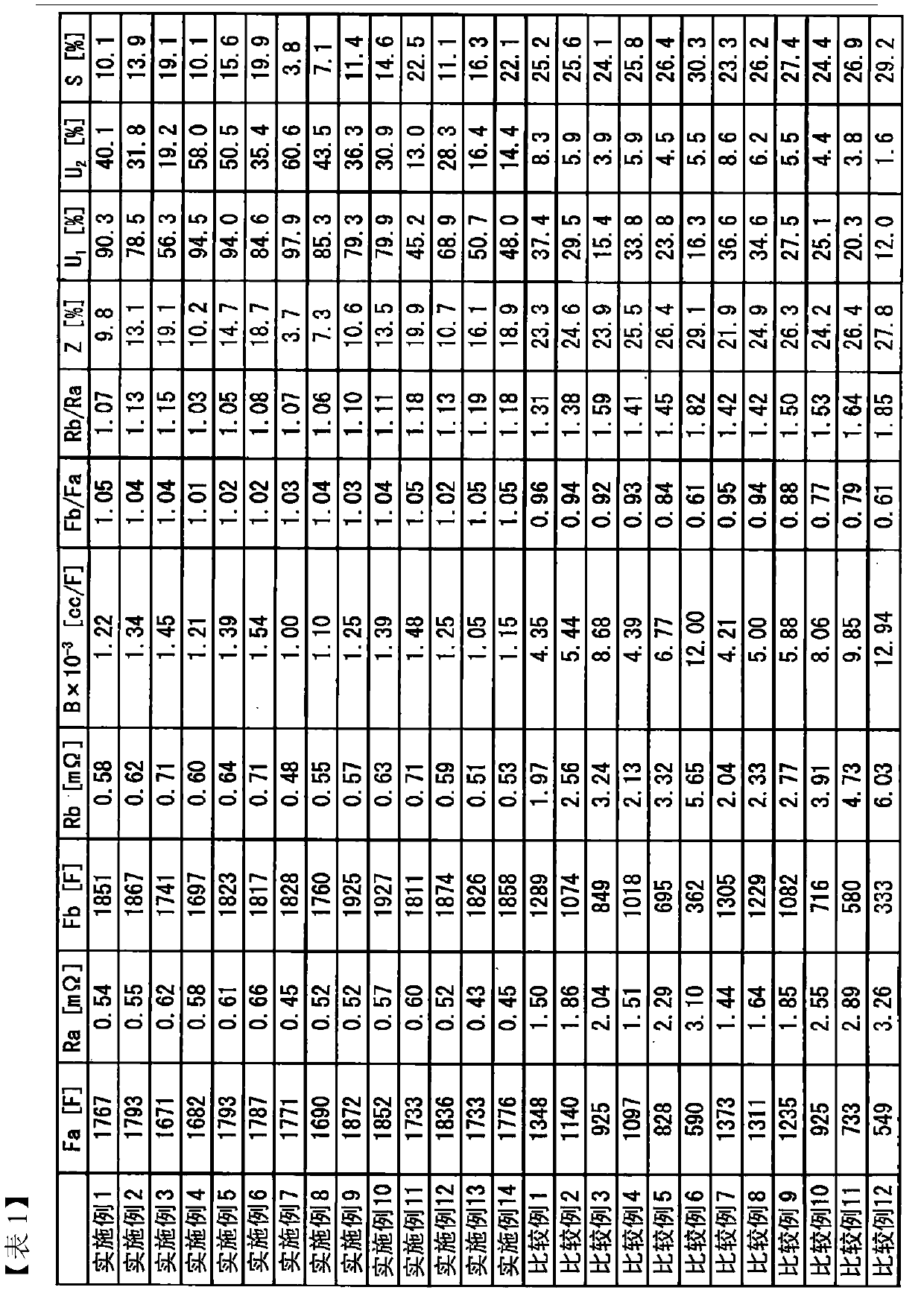

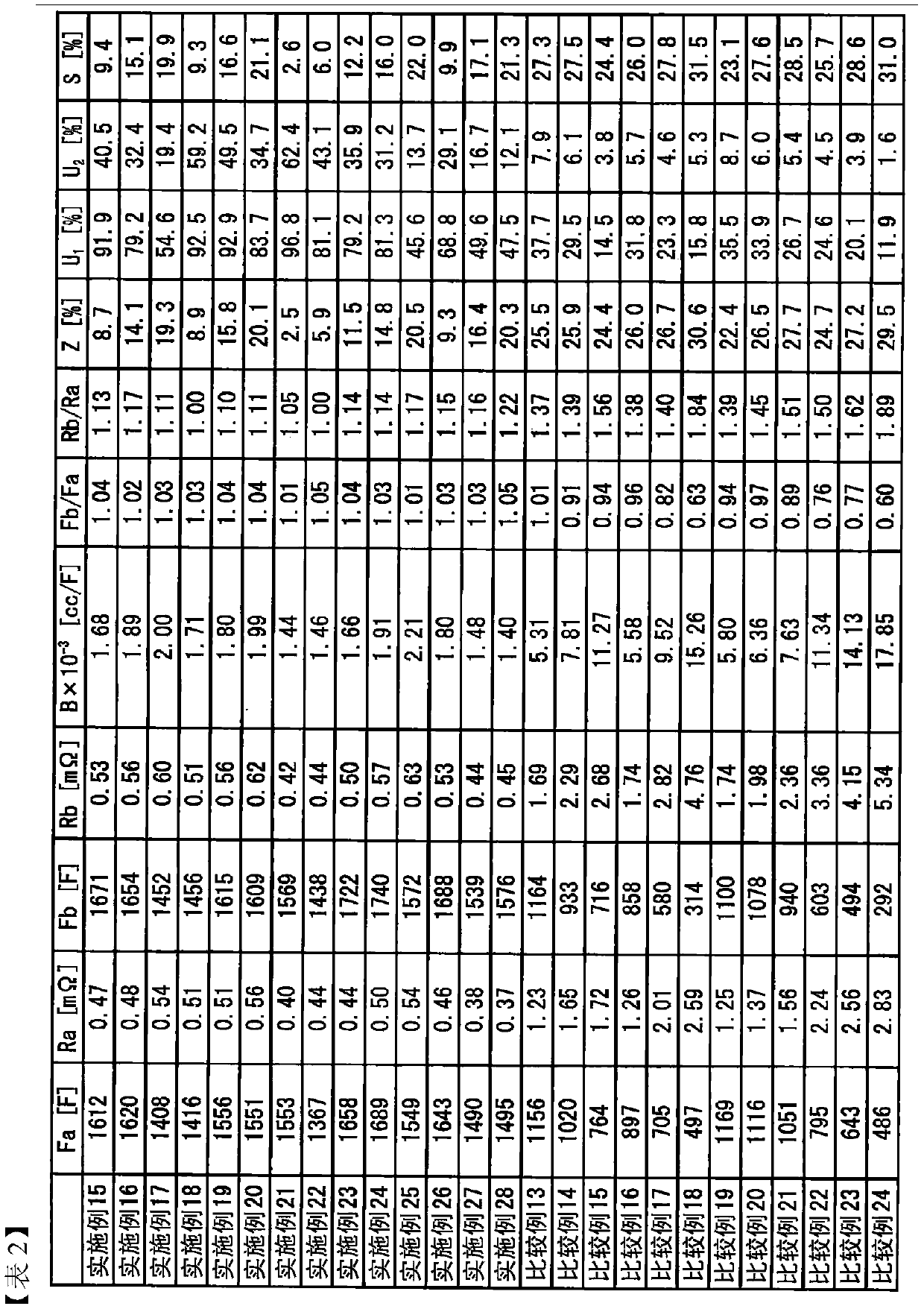

Examples

preparation example Construction

[0272] The preparation method of the coating liquid of the positive electrode precursor is not particularly limited, and a disperser such as a homodisperser, a multi-shaft disperser, a planetary mixer, a thin film rotary high-speed mixer, and the like can be suitably used. In order to obtain a coating liquid in a good dispersion state, it is preferable to disperse at a peripheral speed of 1 m / s to 50 m / s. When the peripheral speed is 1 m / s or more, various materials can be dissolved or dispersed well, which is preferable. When the peripheral speed is 50 m / s or less, various materials are less likely to be damaged by heat or shear force due to dispersion, and re-agglomeration is less likely to occur, which is preferable.

[0273] Regarding the dispersion degree of the coating liquid, the particle size measured by a particle size meter is preferably 0.1 μm or more and 100 μm or less. As the upper limit of the degree of dispersion, the particle size is more preferably 80 μm or l...

Embodiment 1

[0511]

preparation example

[0513] The broken coconut shell carbides were carbonized in a small carbonization furnace at 500° C. for 3 hours under a nitrogen atmosphere to obtain carbides. Put the obtained carbides into the activation furnace, introduce 1 kg / h of water vapor into the activation furnace in the state of being heated by the preheating furnace, and raise the temperature to 900°C for 8 hours for activation. The activated carbide was taken out and cooled under a nitrogen atmosphere to obtain activated activated carbon. The obtained activated carbon was washed with water for 12 hours to remove water. Thereafter, it was dried in an electric dryer maintained at 125°C for 10 hours, and then pulverized with a ball mill for 1 hour to obtain activated carbon 1a 1 .

[0514] For the activated carbon 1a 1 , The average particle diameter was measured using a laser diffraction particle size distribution analyzer (SALD-2000J) manufactured by Shimadzu Corporation, and it was 12.7 μm. In addition, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com