6-amino-1-hexanol adsorption type hydrogen peroxide bleaching stabilizer

A hydrogen peroxide, adsorption-type technology, applied in the direction of bleaching products, textiles and papermaking, liquid/gas/steam textile material treatment, etc., can solve the problem of reduced suspension and adsorption, hardened handle of processed fabrics, and low pH buffering capacity and other problems, to achieve the effect of inhibiting excessive decomposition, increasing whiteness, and little impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

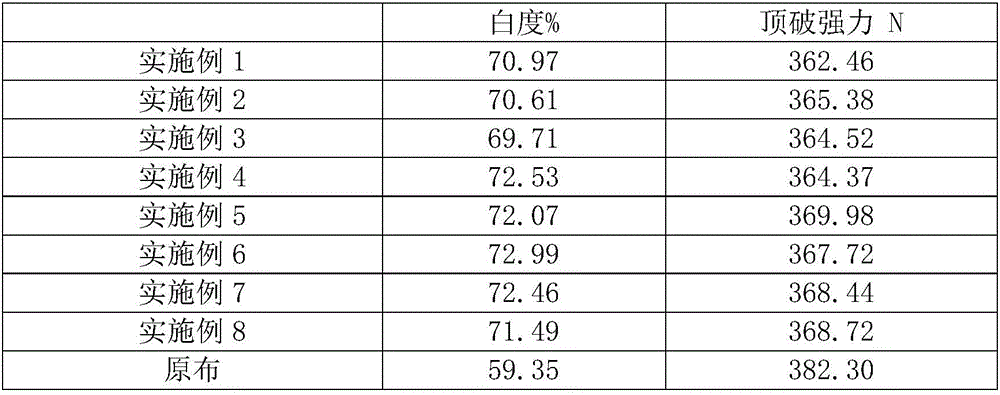

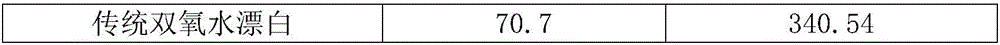

Examples

Embodiment 1

[0026] A 6-amino-1-hexanol adsorption type hydrogen peroxide bleaching stabilizer, made of the following components in parts by weight: 0.1 part of 6-amino-1-hexanol, 2 parts of activated carbon, 0.1 part of urea, water 10 parts; its preparation method is:

[0027] Mix urea and water, add dropwise 6-amino-1-hexanol and stir evenly, add activated carbon and let it stand at low temperature for 10 hours, then filter and remove the activated carbon to obtain a hydrogen peroxide bleaching stabilizer.

Embodiment 2

[0029] A 6-amino-1-hexanol adsorption type hydrogen peroxide bleaching stabilizer, made of the following components in parts by weight: 3 parts of 6-amino-1-hexanol, 5 parts of activated carbon, 0.4 part of urea, water 20 parts; its preparation method is:

[0030] Mix urea and water, add dropwise 6-amino-1-hexanol and stir evenly, add activated carbon and let stand at low temperature for 20 hours, then filter and remove the activated carbon to obtain a hydrogen peroxide bleaching stabilizer.

Embodiment 3

[0032] A 6-amino-1-hexanol adsorption type hydrogen peroxide bleaching stabilizer, made of the following components in parts by weight: 0.1 part of 6-amino-1-hexanol, 5 parts of activated carbon, 0.1 part of urea, water 20 parts; its preparation method is:

[0033] Mix urea and water, add dropwise 6-amino-1-hexanol and stir evenly, add activated carbon and let it stand at low temperature for 10 hours, then filter and remove the activated carbon to obtain a hydrogen peroxide bleaching stabilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com