Plasma processing apparatus

A plasma and processing device technology, which is applied in the field of plasma processing devices, can solve problems such as excessive acceleration, defect formation, and disordered arrangement, and achieve the effect of improving characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

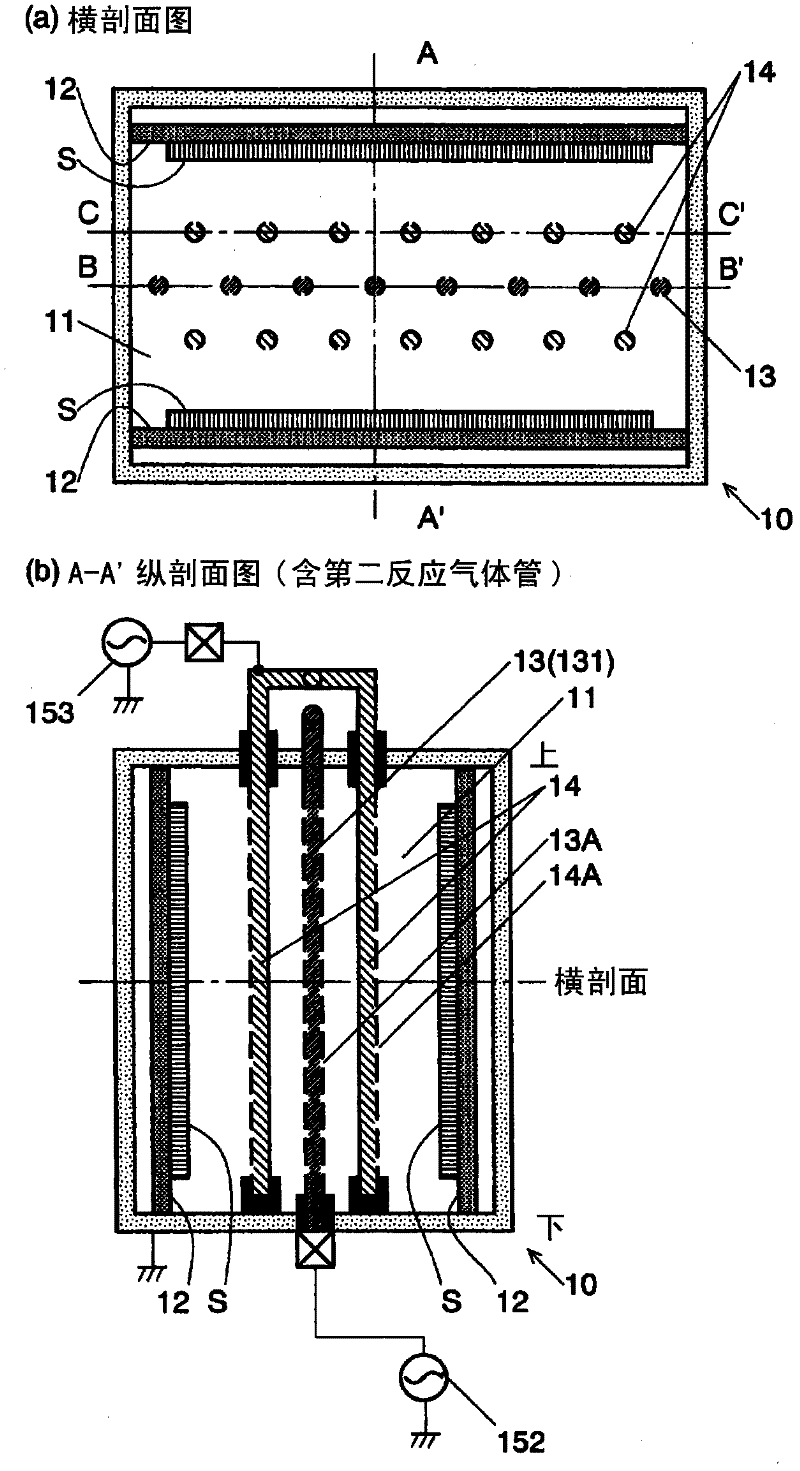

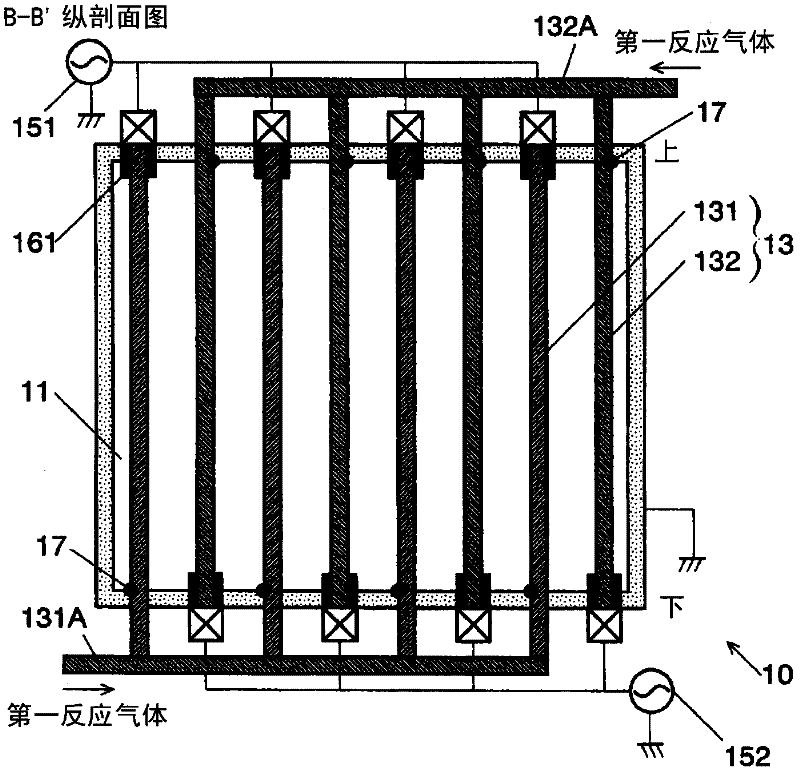

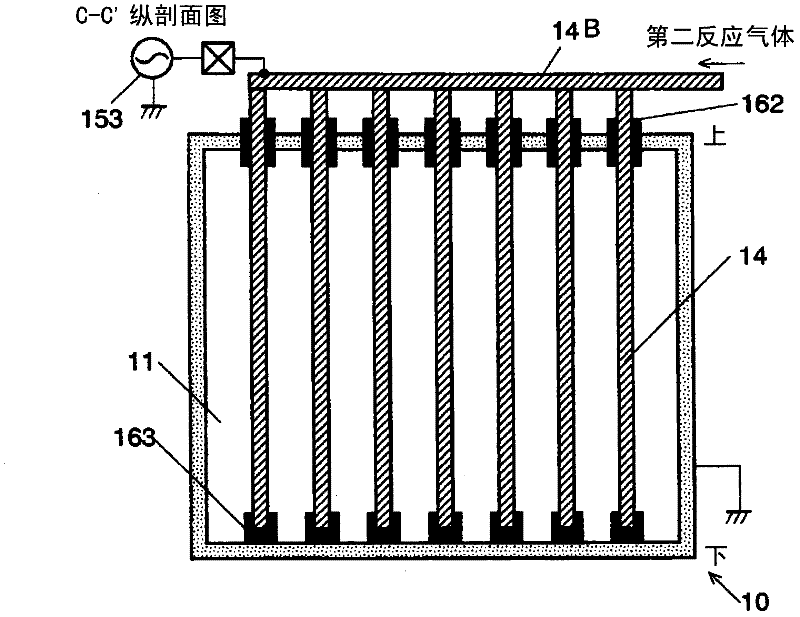

[0057] Figure 1 ~ Figure 3 shows the plasma processing apparatus 10 of the first embodiment, wherein figure 1 (a) is a cross-sectional view, figure 1 (b), figure 2 and image 3 Indicates longitudinal sections at mutually different positions.

[0058] The plasma processing apparatus 10 has the following: a plasma processing chamber 11 composed of a vacuum container; a pair of substrate holding parts 12 erected in a face-to-face manner in the plasma processing chamber 11; a plurality of first reaction gas pipes 13; a plurality of second reaction gas pipes 14 provided between each of the two substrate holding parts 12 and the first reaction gas pipes 13.

[0059] The substrate holder 12 is grounded via the wall surface of the plasma processing chamber 11 . In addition, a heater for heating the held substrate S is incorporated in the substrate holding portion 12 .

[0060] The first reactive gas pipe 13 is a pipe for supplying a first reactive gas into the plasma process...

Embodiment 2

[0073] use Figure 4 , to illustrate the second embodiment of the plasma processing apparatus of the present invention. In the plasma processing apparatus 10A of the second embodiment, one substrate holding portion 12A for substantially horizontally holding the substrate S is provided in the plasma processing chamber 11 . The substrate S is placed on the substrate holding portion 12A. Only one set of the second reaction gas tubes (electrodes) 14 is provided so as to match the number of the substrate holding parts 12A. In addition, a DC bias power supply 154 is connected to the second reaction gas pipe 14 . Except for these points, the plasma processing apparatus 10A of the second embodiment has the same configuration as the plasma processing apparatus 10 of the first embodiment. In addition, the operation of the plasma processing apparatus 10A of the second embodiment is also the same as that of the plasma processing apparatus 10 of the first embodiment.

Embodiment 3

[0075] use Figure 5 , a third embodiment of the plasma processing apparatus of the present invention will be described. In the plasma processing apparatus of the third embodiment, the high-frequency antenna 21 and the first reaction gas pipe 22 are provided independently. Specifically, the high-frequency antenna 21 is formed of linear conductor rods extending in the vertical direction, and is arranged in parallel in the plasma processing chamber 11 . To the high-frequency antenna 21, the first high-frequency power supply 151 or the second high-frequency power supply 152 is connected alternately in the order of arrangement so that currents flow in opposite directions. The first reaction gas pipes 22 are respectively provided on the upper wall and the lower wall of the plasma processing chamber 11 , and their open ends are arranged in the plasma processing chamber 11 . The first reaction gas pipe 22 is disposed between two adjacent high-frequency antennas. By arranging the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com