High-safety lithium ion battery and preparation method thereof

A lithium-ion battery, high-safety technology, applied in the direction of secondary batteries, battery pack components, secondary battery repair/maintenance, etc., can solve problems such as safety hazards, mechanical abuse, thermal abuse, etc., to improve safety, Prevent positive and negative crosstalk and suppress thermal runaway effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

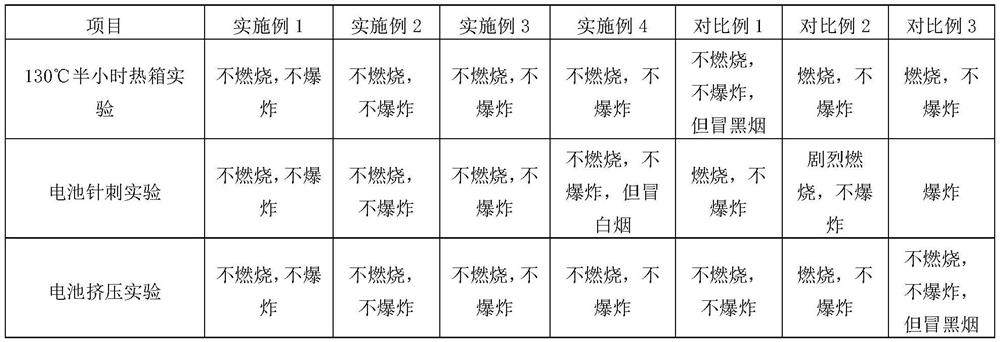

Examples

Embodiment 1

[0050] A preparation method of a high-safety lithium-ion battery, comprising the steps of:

[0051] S1. Preparation of positive pole piece: Lithium cobaltate, conductive agent SP, binder polyvinylidene fluoride and inorganic flame retardant component magnesium oxide are prepared into slurry according to the mass ratio of 95.5:3:1.5:5, coated and dried , rolling, and slitting to prepare the positive electrode sheet;

[0052] S2. Preparation of negative pole piece: mix 9g of graphite with 0.5g of conductive agent SP, then add 0.5g of PVDF and 40ml of NMP to prepare negative pole slurry, apply it on aluminum foil, and prepare negative pole piece by drying, rolling and cutting ;

[0053] S3. Preparation of electrolyte: The electrolyte solvent is made of EC, EMC, and DEC with a mass ratio of 1:1:1; the electrolyte is 1mol / L lithium hexafluorophosphate; 3% di Lithium fluorooxalate borate (LiDFOB), 3% ethylene sulfate (DTD), 5% ethoxypentafluorocyclotriphosphazene, 0.8‰ potassium p...

Embodiment 2

[0063] In this embodiment, lithium cobaltate, conductive agent SP, binder polyvinylidene fluoride, and inorganic flame retardant component magnesium oxide are configured according to the mass ratio of 95.5:3:1.5:1; except for the above matters, the same as the embodiment 1 The same method is used to manufacture lithium-ion batteries.

Embodiment 3

[0065] In this example, 1% of lithium difluorooxalate borate (LiDFOB), 1% of ethylene sulfate (DTD), 3% of ethoxylated pentafluorocyclotriphosphazene, 0.5‰ of all Potassium fluorobutanesulfonate;

[0066] Except for the above matters, a lithium ion battery was produced in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com