Inverter device

An inverter and fuse technology, applied in the field of general inverter devices, can solve the problems of increasing the horizontal width of the substrate 1, increasing the interval D, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

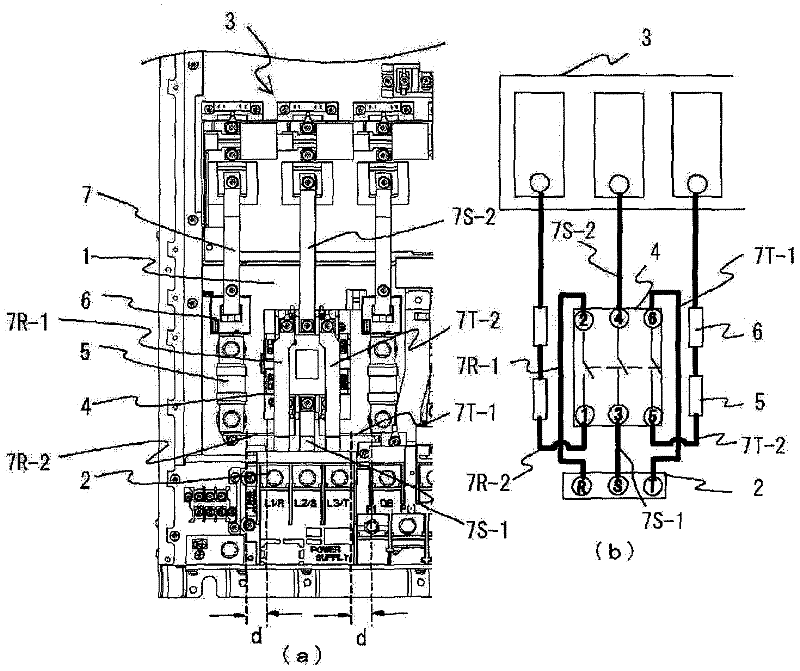

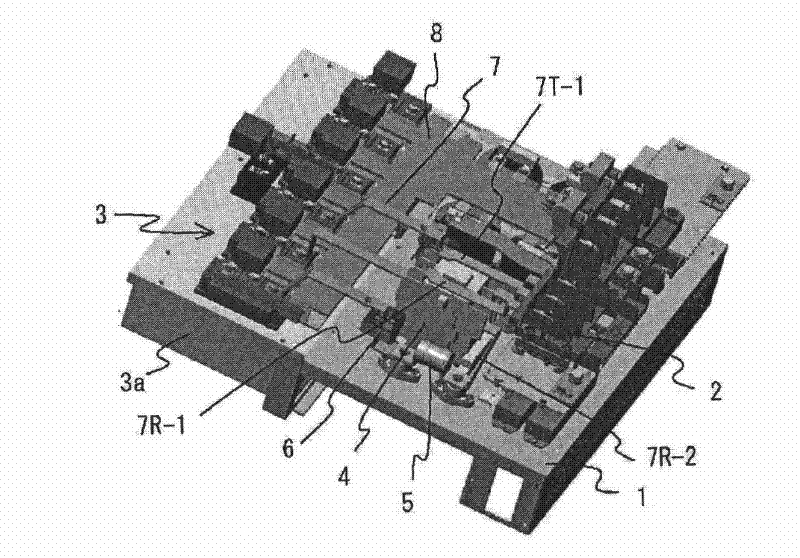

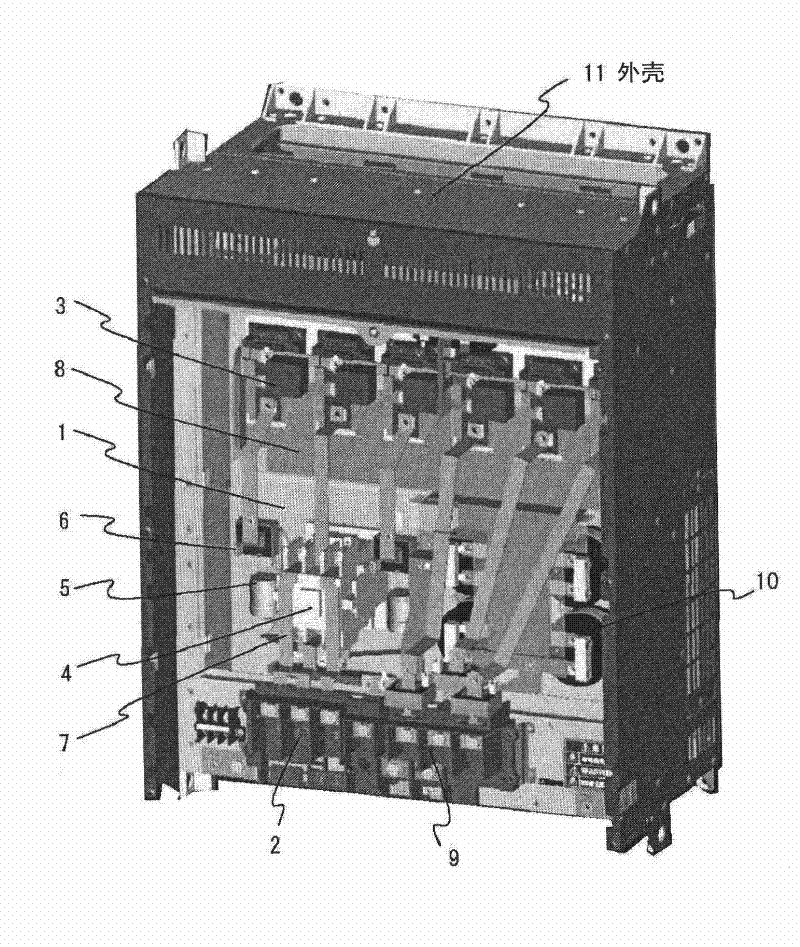

[0025] Below, based on figure 1 A~ image 3 The illustrated examples describe the implementation of the invention. For with Figure 4 ~ Figure 7 Components in the corresponding embodiment figures are given the same reference numerals and numerals, and descriptions thereof are omitted.

[0026] figure 1 A. figure 1 B. and figure 2 The layout of the main circuit components shown is basically the same as Figure 6 and Figure 7 As in the comparative example 2 shown, the series connection body of the fuse 5 and the input CT 6 between the R phase and the T phase of the input power supply is arranged side by side across the left and right sides of the electromagnetic contactor 4, but from the input terminal block 2. The wiring path of the bus bar connected to the fuse 5 via the electromagnetic contactor 4 is formed as follows.

[0027] That is, for the power supply R phase and T phase in which the fuse 5 and the input CT 6 are interposed, contrary to the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com