Automobile glass blasting system

A technology for automotive glass and glass, applied in windshields, vehicle parts, and anti-war damage, etc., can solve the problems of difficult control of detonator blasting force, unfavorable smooth escape, complex glass structure, etc., so as to reduce the difficulty of escape and ease of force. Controls and increases the chance of escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

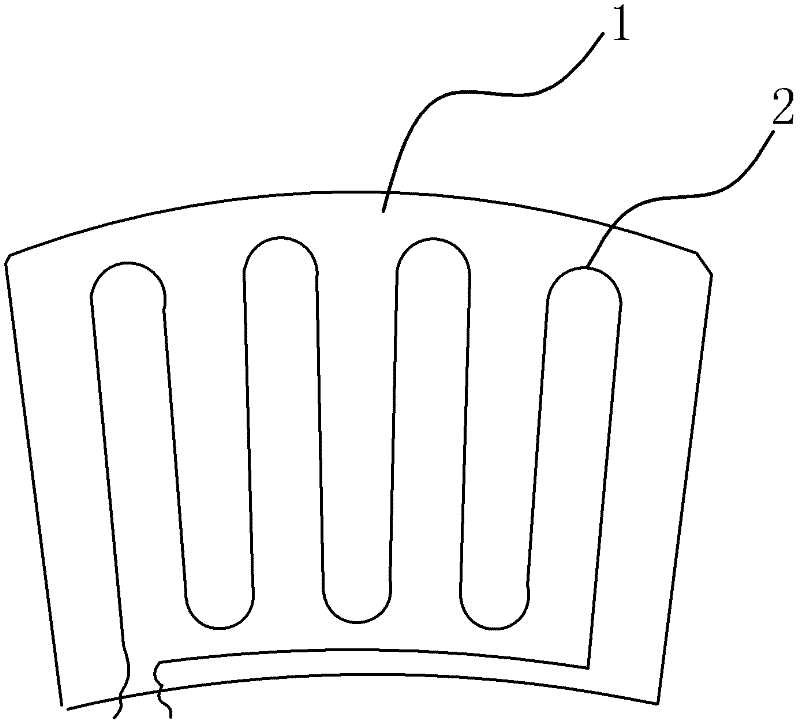

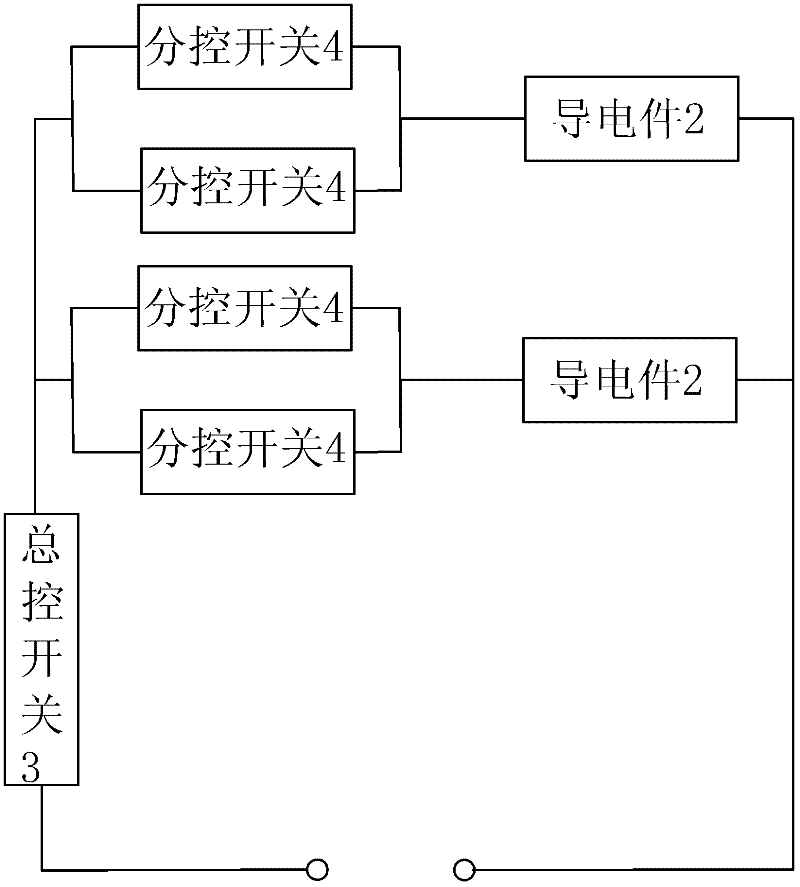

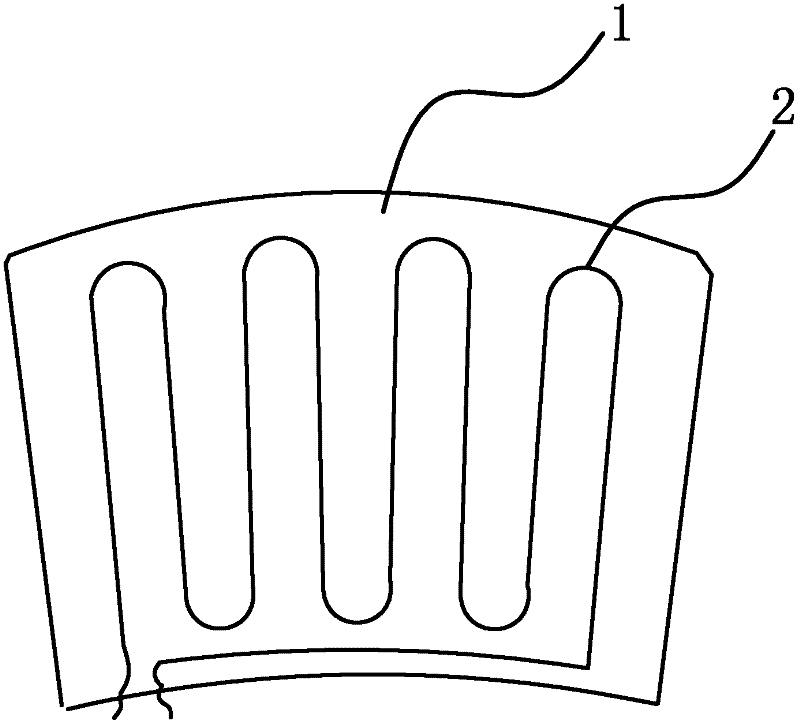

[0027] Such as figure 1 , figure 2 As shown, the automobile glass blasting system includes conductive parts 2, master control switch 3, sub-control switch 4 and other components.

[0028] Specifically, the toughened glass is installed on the window of the car, and the conductive elements 2 are evenly embedded in the toughened glass. The conductive member 2 can be expanded graphite, or a heating wire, and of course can also be made of other materials that can break glass after conducting electricity. Expanded graphite has good electrical conductivity. After conducting electricity, it will expand when heated, and its expansion coefficient is very high, which can instantly break the glass. The heating wire can generate he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com