Filling pile concrete guide pipe assembling and disassembling device and construction method thereof

A technology of cast-in-situ piles and conduits, which is applied to sheet pile walls, foundation structure engineering, buildings, etc., can solve the problems of continuous on-site construction, large construction site occupation, inflexible operation, etc., and achieves simple structure, reduced engineering cost, Mobile and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

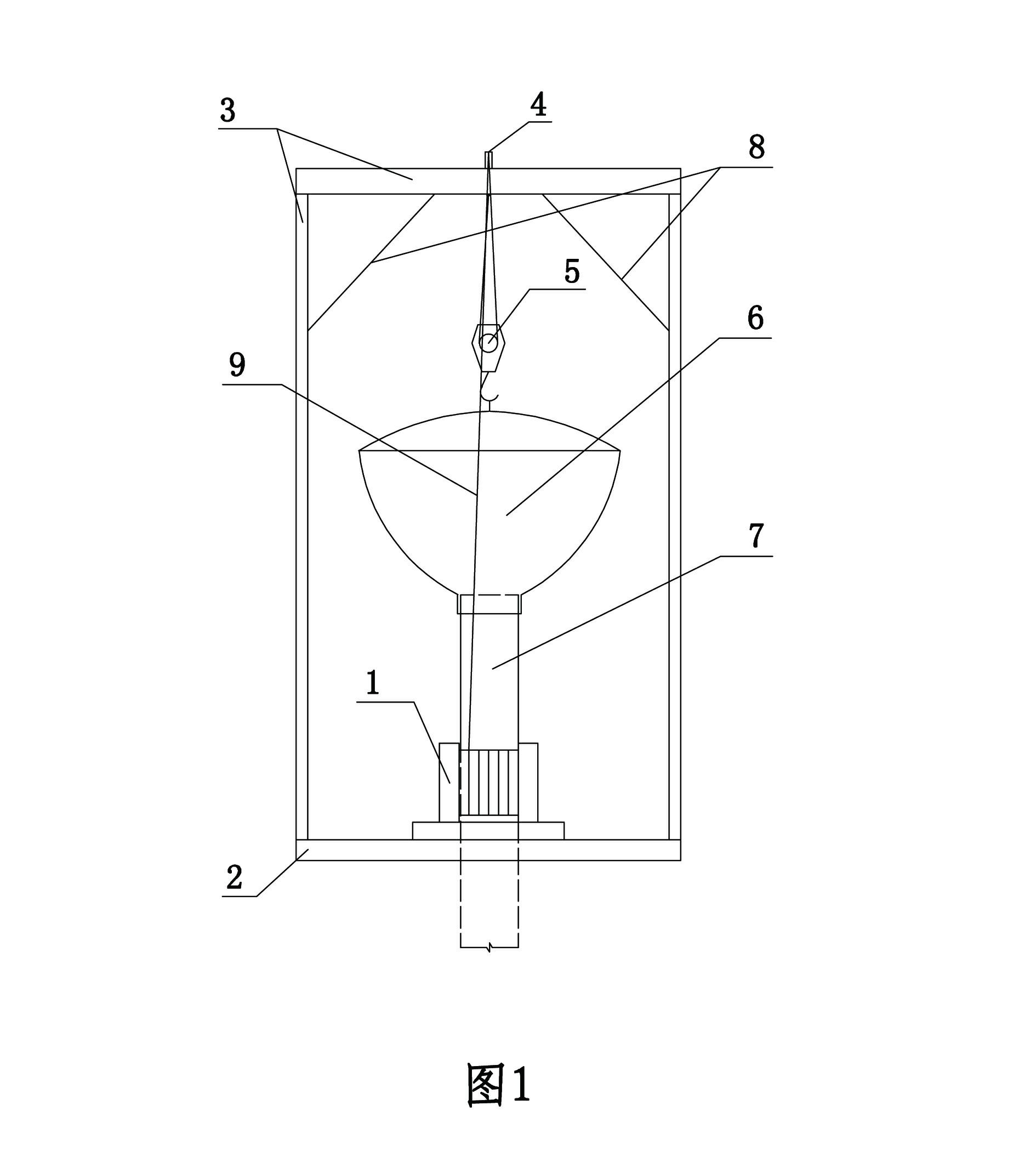

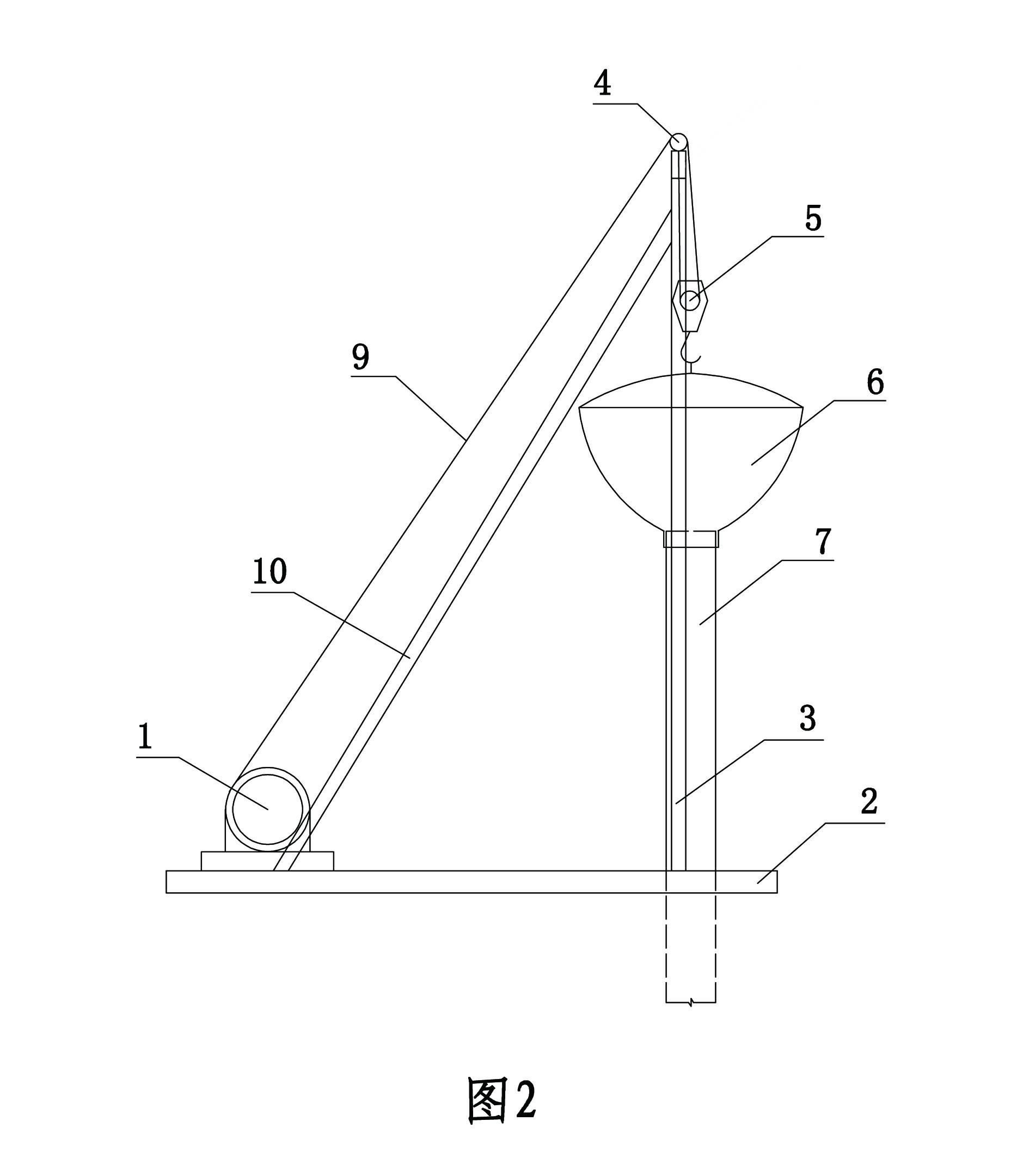

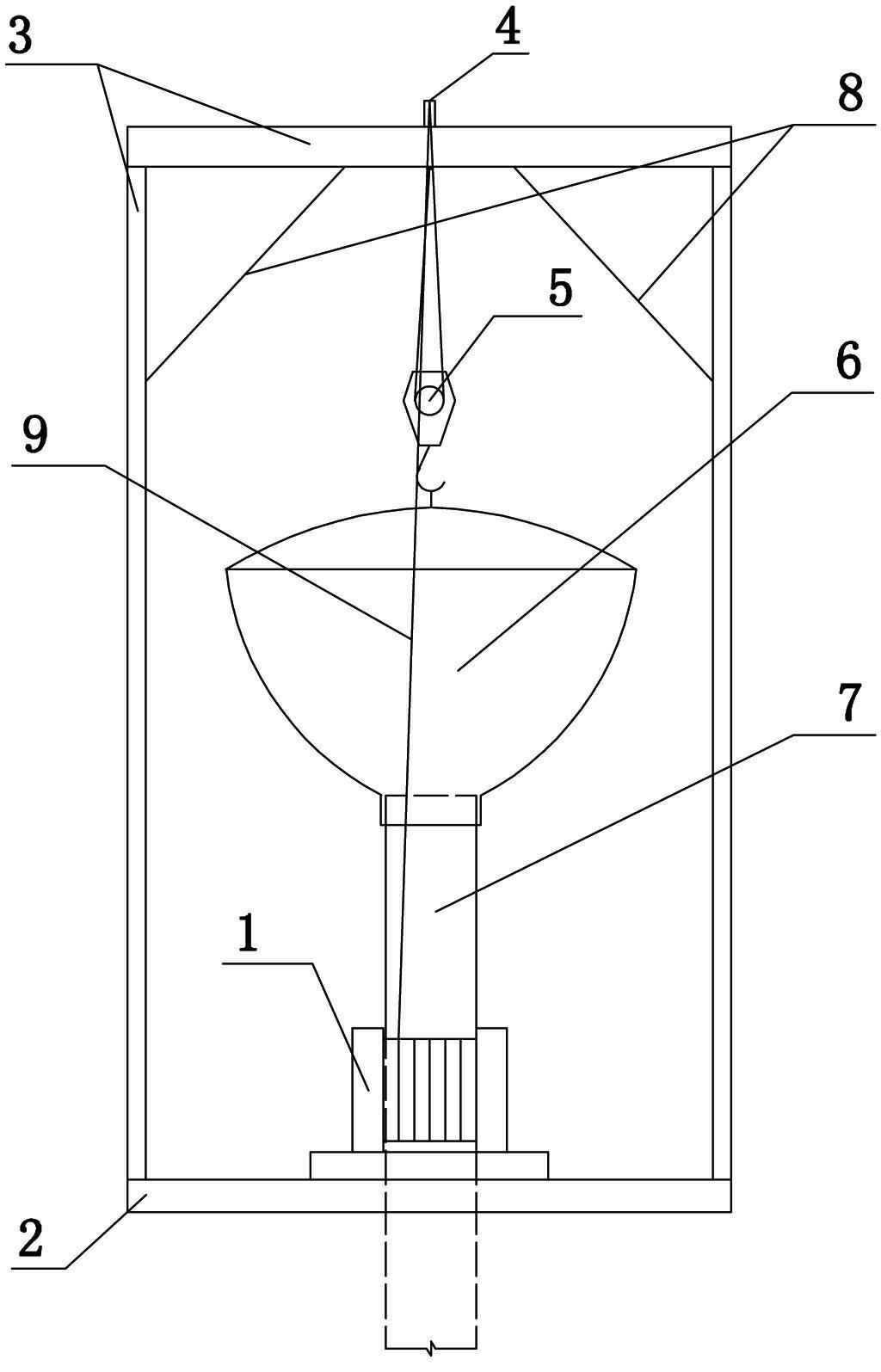

[0022] Examples see figure 1 , figure 2 As shown, a device for installation and disassembly of cast-in-situ pile concrete conduits includes a frame and a hoisting system. The frame is formed by connecting a base 2, a door frame 3 and two diagonal braces 10, and the door frame 3 is connected to the base On one side, the lower ends of the two diagonal braces 10 are connected to the other side of the base, and the upper ends of the two diagonal braces 10 are connected to the upper parts of the two door posts of the mast; the hoisting system includes a guide wheel 4 placed in the center of the mast 1. The hoist 1 placed between the two diagonal braces in the middle of the base, the wire rope 9 wound on the hoist and passing through the guide wheel 4, and the pulley hook 5 for installing and removing the concrete conduit 7 or hopper 6 and connected to the wire rope.

[0023] Two upper corners of the door frame 3 are respectively connected with pull rods 8 .

[0024] The upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com