Design method of double helix mixed flow pump impeller

A design method and technology of mixed-flow pumps, which are applied to components, pumps, and pump components of pumping devices for elastic fluids, and can solve problems such as vibration and noise, increased instability, and uneven mass distribution of the pump body , achieve the effect of reducing vibration and noise and improving the balance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

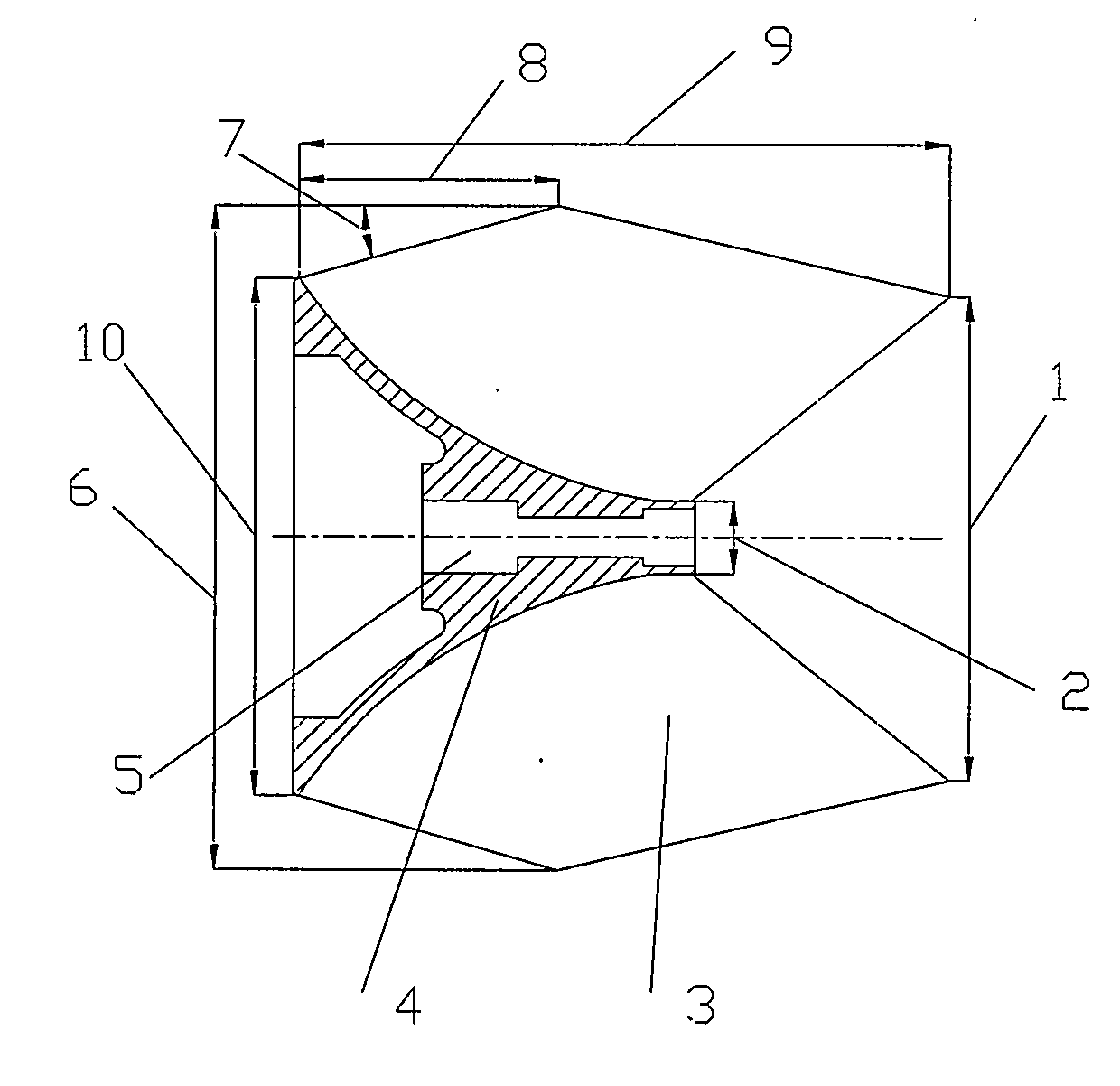

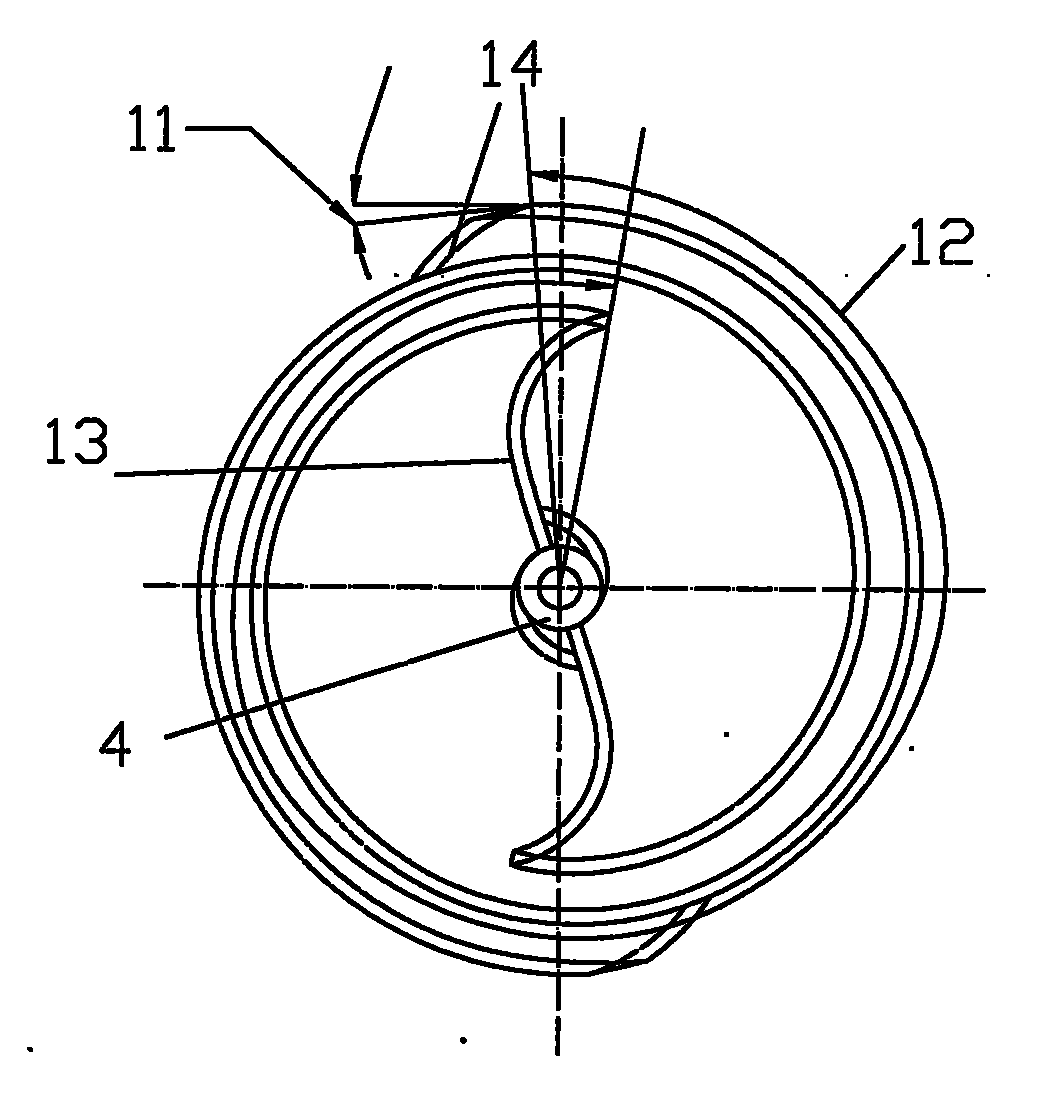

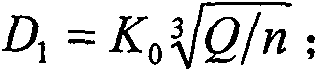

[0051] figure 1 and figure 2 Together determine the impeller shape for this embodiment. It is different from the common mixed-flow pump impeller. The impeller inlet is a spiral forward type. The inlet side (13) looks like a sickle shape. The blades (3) spiral upward along the hub (4), and the number of blades (3) is only Two, symmetrically arranged blades have a good balancing effect. And it has a large flow channel, which has good passing performance and non-destructive properties. The present invention determines the impeller inlet diameter D through the following relations 1 (1), impeller hub diameter d h (2), the maximum outer diameter of the impeller D 20 (6), the outlet edge inclination angle α 2 (7), outlet side width b 2 (8), the axial length of the impeller L (9) and the minimum outer diameter of the impeller D 2h (10).

[0052] D 1 = K 0 Q ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com