Free-film type anti-inclination air spring

An air spring, anti-tilt technology, applied in the direction of elastic suspension, gas shock absorber, suspension, etc., can solve the loss of air spring shock absorption, low lateral positioning stiffness, air spring lateral stop gap and vertical stop gap. Insufficient and other problems, to achieve the effect of vertical and lateral limit, simple and compact structure, and improved bearing condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

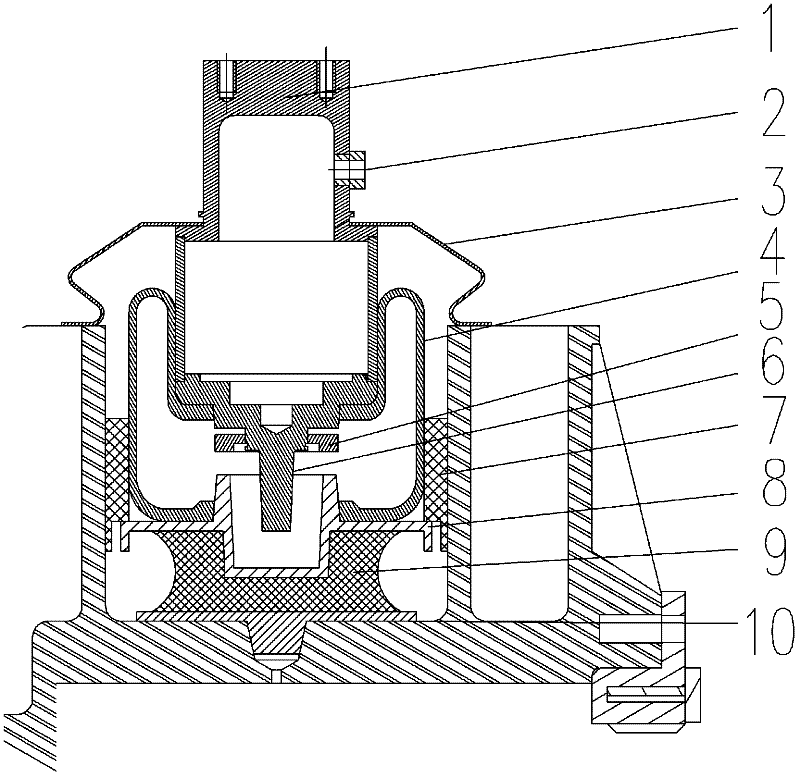

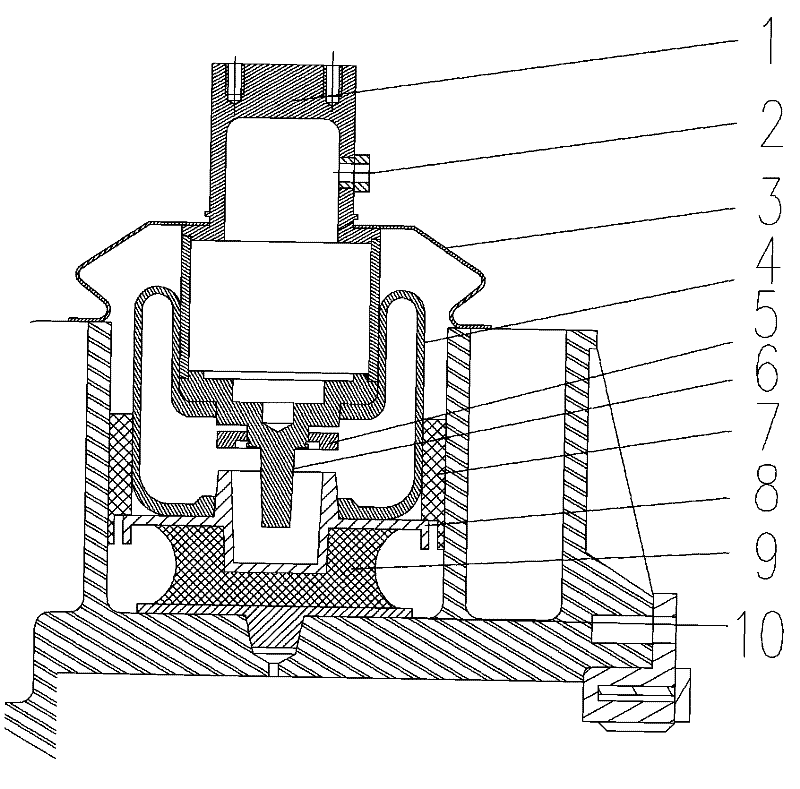

[0022] Example by figure 1 Shown, a kind of specific embodiment of the present invention is:

[0023] A free-membrane anti-tilt air spring, including a rubber pile 9 located on the lower base 10, the bottom of the rubber bag 4 is fastened to the stop seat 8 on the top of the rubber pile 9, and the top of the rubber bag 4 is connected to the upper top plate 1 The bottom edge of the upper top plate 1 is fastened, and a dust-proof sealing cover 3 is provided between the upper top plate 1 and the mounting seat. the whole frame. The welded overall structure is a cavity structure with a narrow top and a wide bottom. The convex shoulder of the cylindrical pin 6 is fixedly connected to the friction block 5, the rubber block 4 is provided with a rubber block 7 under the side of the rubber bag 4, the center part of the stop seat 8 has a concave to match the concave of the rubber stack 9, and the upper wall top of the stop seat 8 The distance between the friction block 5 is less than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com