Automotive air conditioning motor-driven oil return device

An automotive air-conditioning and electric technology, applied in the direction of compressors, refrigeration safety arrangements, refrigeration components, etc., can solve problems such as insufficient lubrication, compressor operation failure, compressor oil shortage, etc., to achieve easy production operation, simple installation, and control simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

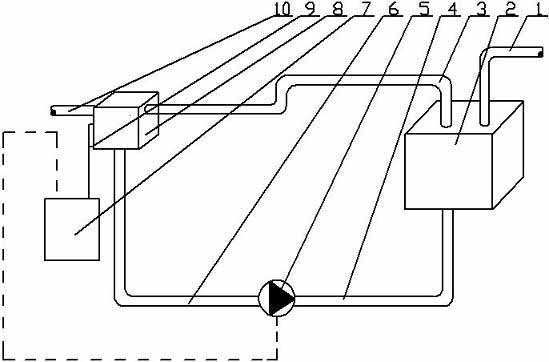

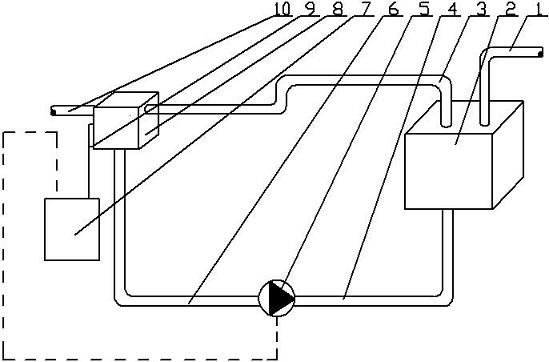

[0016] combine figure 1 The specific embodiment of the present invention is further described:

[0017] According to the technical solution provided by the present invention, an electric oil return device for an automobile air conditioner includes a compressor discharge pipe 1, a compressor 2, a compressor air return pipe 3, a liquid pump discharge pipe 4, a liquid pump 5, and a liquid pump suction pipe 6 , controller 7, oil collecting bag 8, liquid level sensor 9, evaporator pipeline 10, described compressor 2 and condenser, throttle valve, evaporator pipeline 10 are sequentially closed-loop connected, and described oil collecting bag 8 is installed At the lowest point of the evaporator pipeline 10, the liquid pump discharge pipe 4 of the liquid pump 5 is connected to the crankcase of the compressor 2, and the liquid pump suction pipe 7 is connected to the bottom of the oil collection bag 9.

[0018] The output circuit of the controller 8 is connected to the control circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com