Simulation experimental apparatus for lubrication condition of antifriction bearing and measuring method thereof

A technology for rolling bearings and experimental simulation, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as complex motion states, lack of experimental data, and changes in motion components, and achieve intuitive and clear experimental processes, convenient operation, and accurate measurement data Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

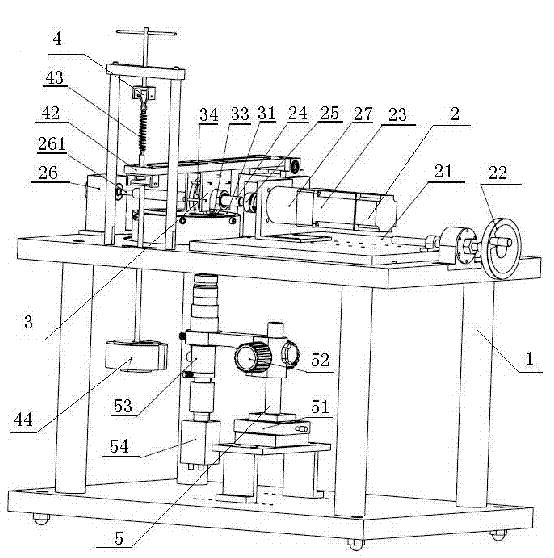

[0029] Such as image 3 As shown, the experimental simulation device for rolling bearing lubrication conditions in this embodiment includes a workbench 1, on which a drive unit 2 is arranged, the drive unit 2 drives the EHL subunit 3, and the Elastohydrodynamic contact subunit 3 is connected to the loading unit 4 , while the Elastohydrodynamic contact sub-unit 3 cooperates with the optical measurement unit 5 .

[0030] The drive unit 2 includes a supporting plate 21 arranged on the table of the workbench 1. The front end of the supporting plate 21 is provided with a hand wheel 22 for controlling plane movement. The rear end of the supporting plate 21 is fixed with a motor 23 with a reducer 27. One end of the rotary shaft 24 The motor 23 is connected through a shaft coupling 25, and the other end is assembled on the thimble 261 of the axle seat 26, and the axle seat 26 is fixed on the table surface of the workbench 1; the rotary shaft 24 drives the rolling bearing 34 to rotate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com