Rapid test and running-in system for flexible driving element utilized by buncher

A technology of continuously variable transmission and flexible transmission, which is applied in the field of quick test run-in system of flexible transmission elements for continuously variable transmission, which can solve the time-consuming problems of loading and unloading metal belts or transmission chains, achieve high rigidity and ensure test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

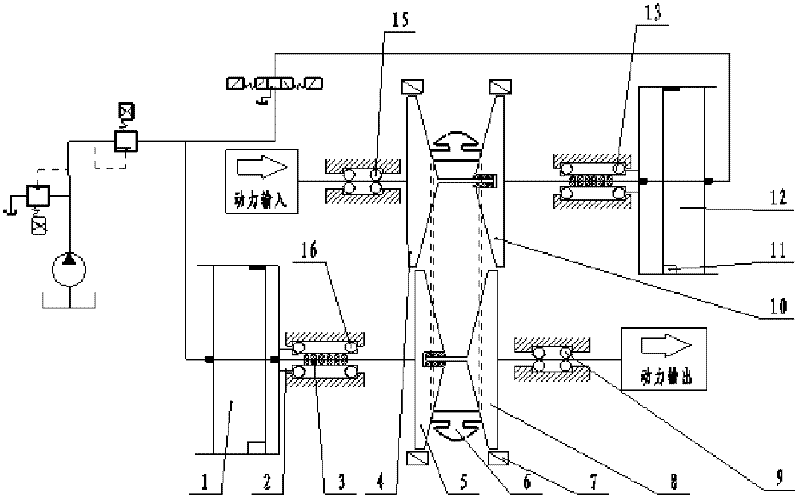

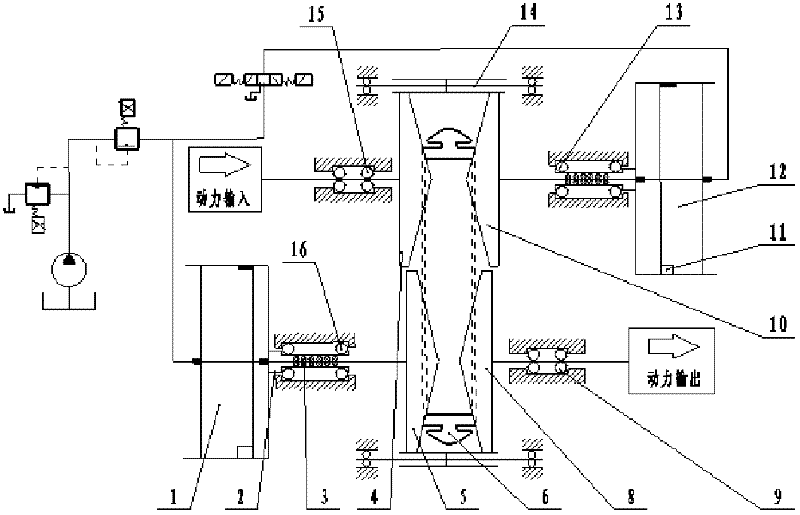

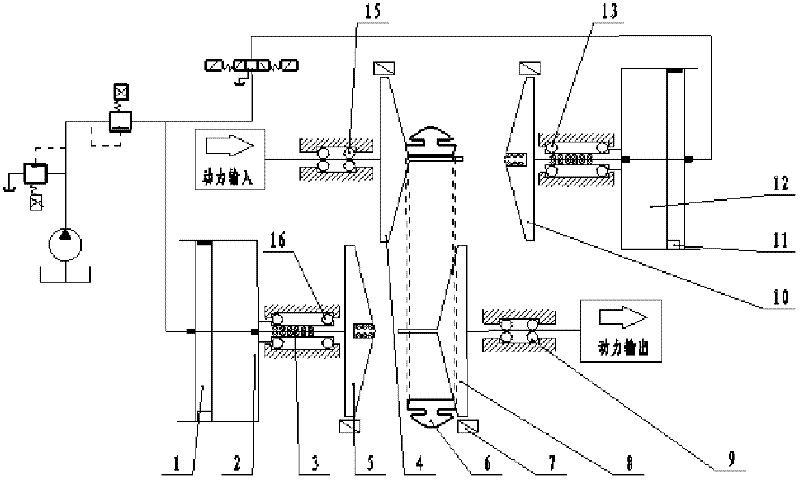

[0029] Such as figure 1 As shown, the transmission structure of one of the fast test run-in system of the flexible transmission element for the continuously variable transmission of the present invention mainly includes: frame, driven oil cylinder 1, oil cylinder positioning slideway 2, linear guide rail 3, driving shaft fixed cone 4, Driven shaft moving cone 5, flexible transmission element 6, braking system 7, driven shaft fixed cone 8, rolling bearing I 9, driving shaft moving cone 10, displacement sensor 11, driving cylinder 12, rolling bearing II13, synchronization Gear 14, rolling bearing III15, rolling bearing IV16, loading and dragging motor and its control and driving system, etc., the specific structure is as follows:

[0030] Four cone shafts are installed on the frame, that is, the shaft on which one cone is installed, and every two cone shafts are arranged coaxially, and the driving shaft, fixed cone 4, and driven shaft are respectively installed on the four cone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com