Desulfurization device applicable to thermal power plant

A technology for thermal power plants and desulfurization devices, which is applied to combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as reducing exhaust gas purification effect, increasing filtration links, secondary pollution, etc., so as to avoid mesh blockage. , the effect of speeding up the filtration and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

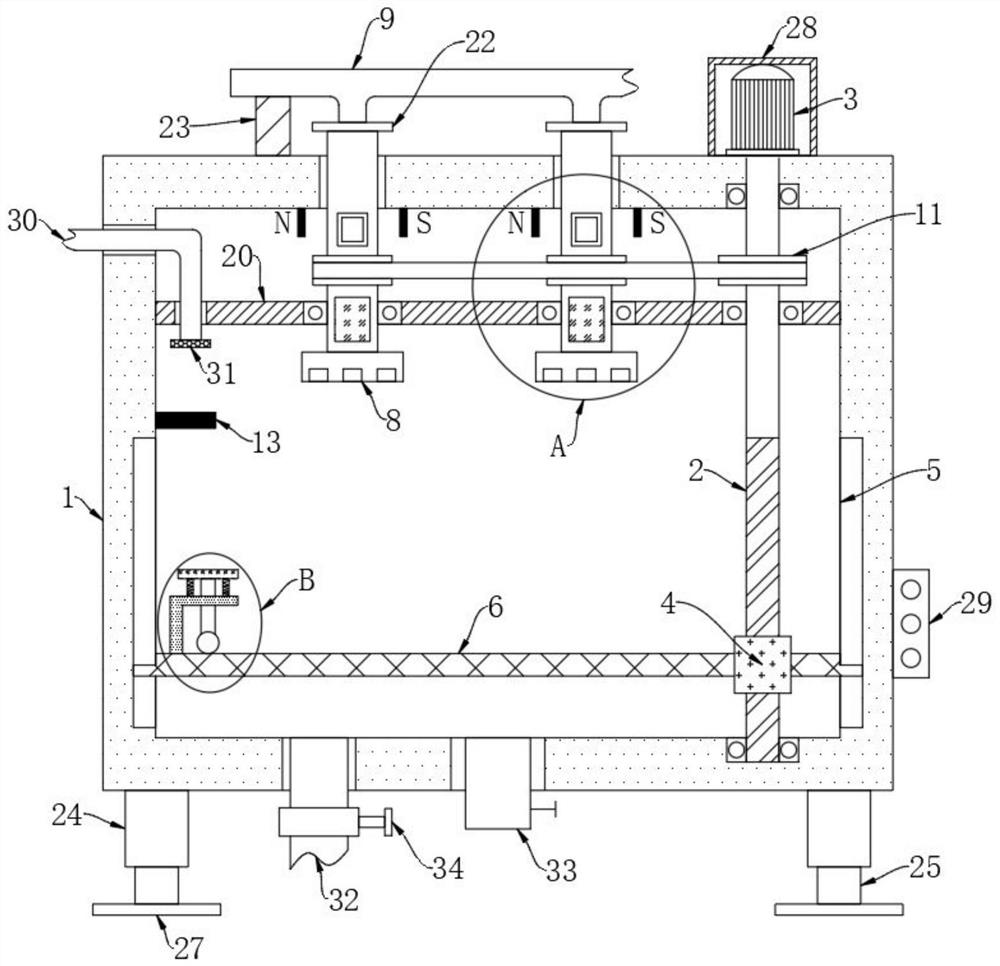

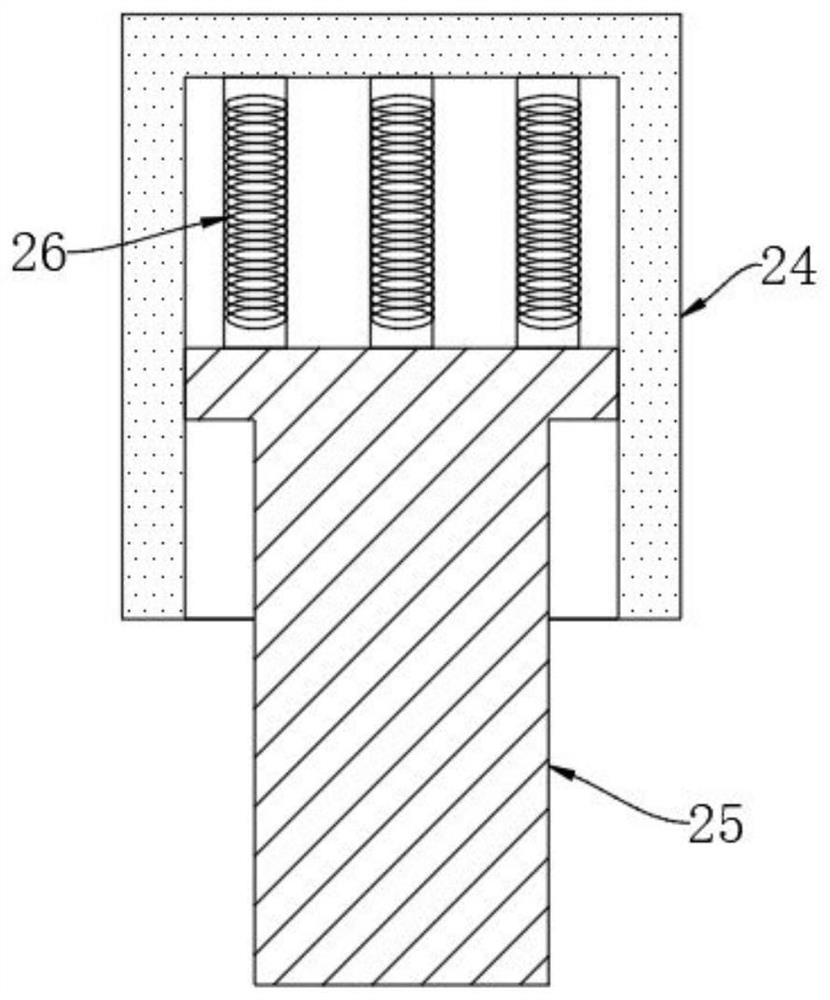

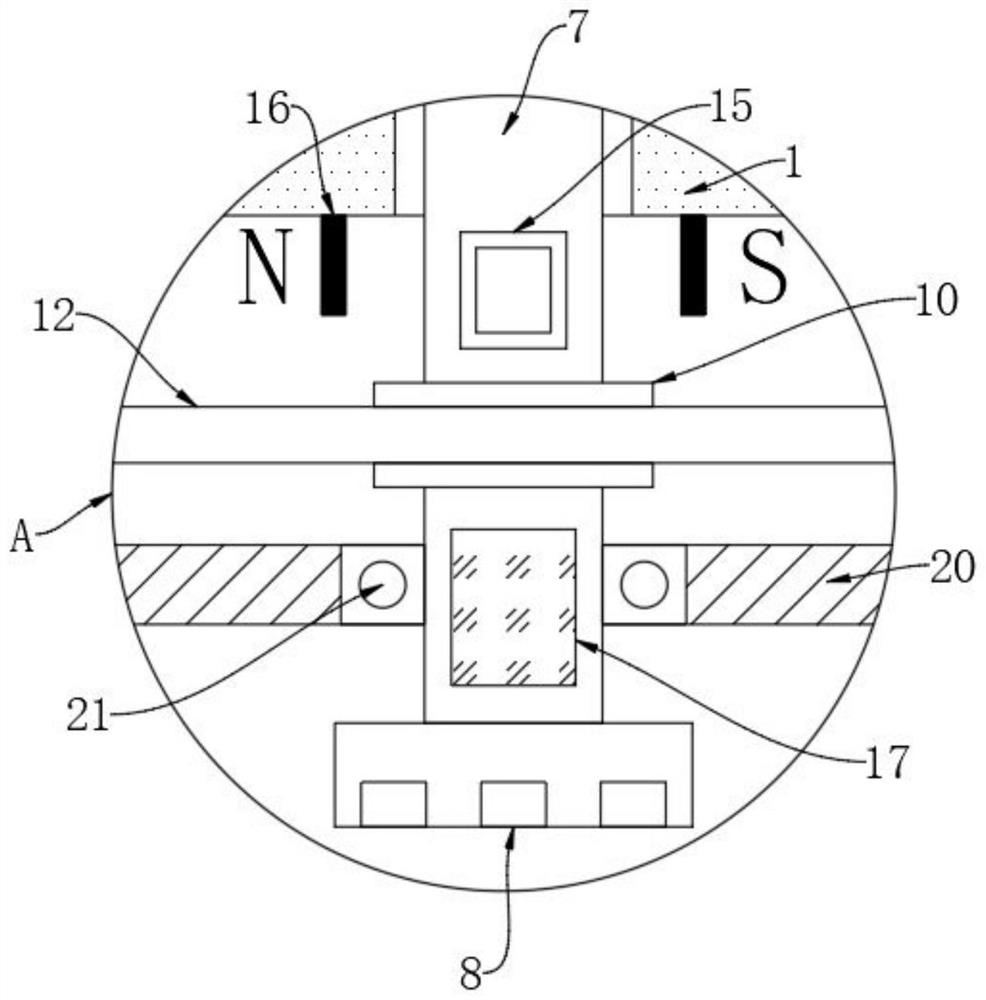

[0031] Such as Figure 1-4 As shown, a desulfurization device suitable for a thermal power plant includes a purification box 1, a plurality of hollow rods 24 are fixedly connected to the side wall of the lower end of the purification box 1, and a support rod 25 is slidably connected to the hollow rod 24, and the support rod 25 A plurality of buffer springs 26 are fixedly connected to the hollow rod 24, and a foot 27 is fixedly connected to the lower end of the support rod 25. The provided support rod 25 can provide stable support for the purification box 1, and the additionally provided hollow rod 24 and The cooperation of the buffer spring 26 can effectively buffer the pressure generated by the purification box 1 to prevent the excessive pressure generated by the purification box 1 from damaging the support rod 25 .

[0032] The upper side wall of the purification box 1 is communicated with an exhaust pipe 30, and the air inlet end of the exhaust pipe 30 penetrates the protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com