One-time extrusion production cooling forming mold for foaming insulating core wire of leakage coaxial cable

A technology of leaky coaxial cables and insulated core wires, applied to leaky waveguide antennas, circuits, electrical components, etc., can solve problems such as uneven outer diameters and affect the quality of coaxial cables, and achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

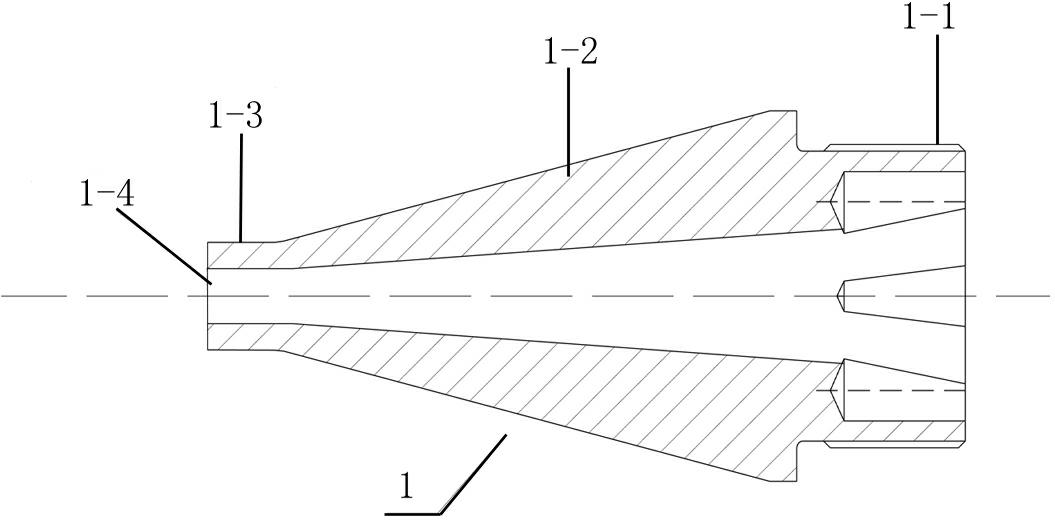

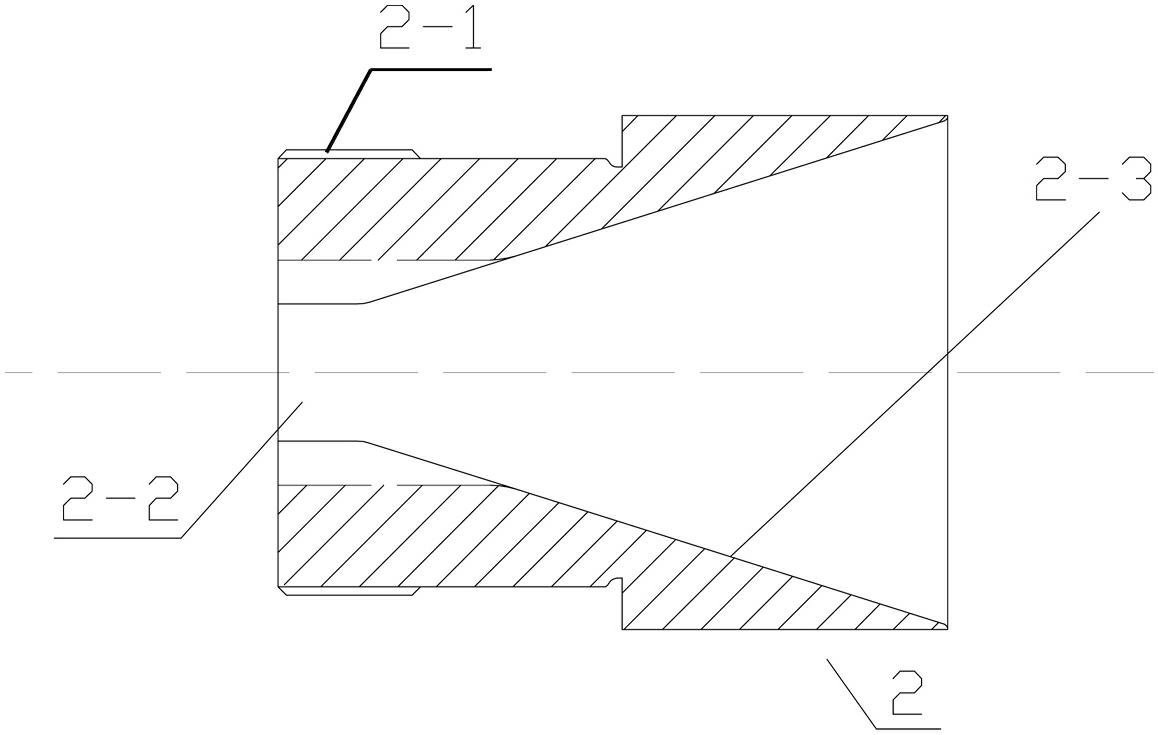

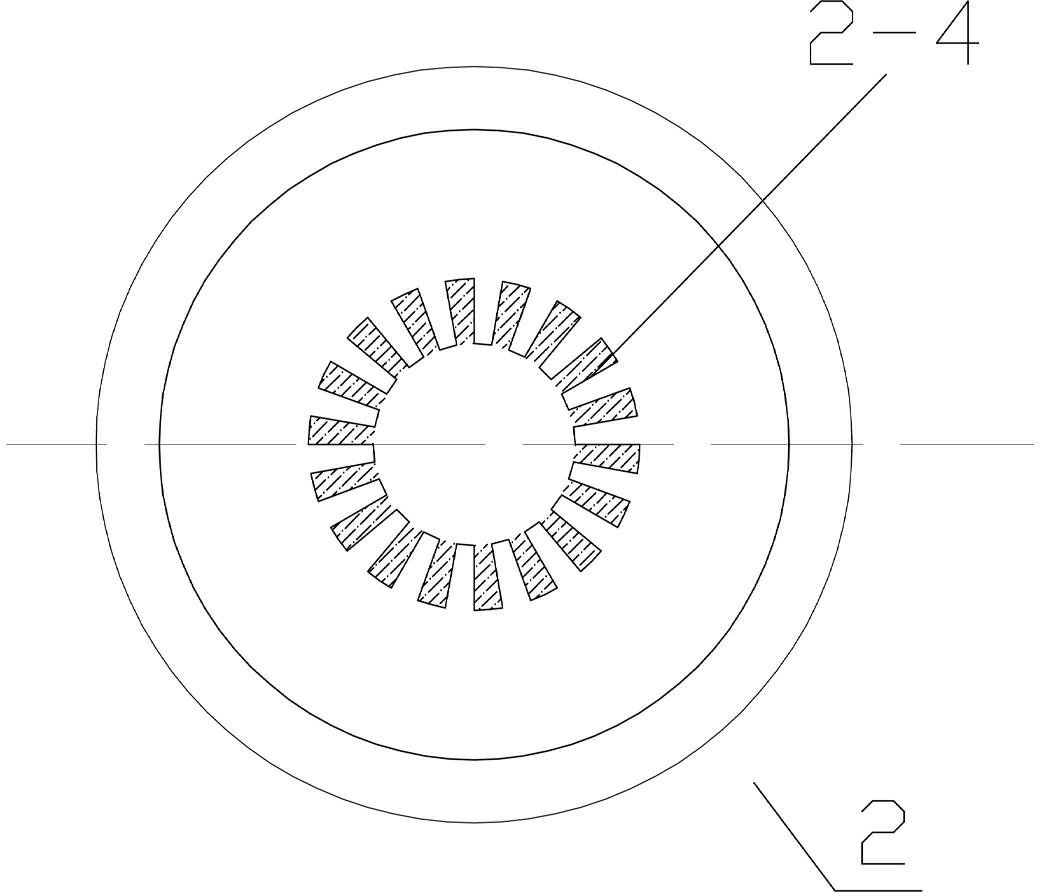

[0022] Refer to attached Figure 1-7 , The leaky coaxial cable foam insulation core wire is extruded once to produce the cooling forming mold, which includes a foam extrusion mold core 1, a foam extrusion mold sleeve 2 and a forced cooling water pipe. The foam extrusion mold core 1 is installed in the foam extrusion mold sleeve 2, and the forced cooling water pipe is installed at the front end of the foam extrusion mold sleeve 2.

[0023] The foam extrusion core includes a core body 1-2, a die nozzle 1-3, a threaded end 1-1 and an inner conductor threading hole 1-4, the core body 1-2 is a cone, and the core body 1-2 The front end is provided with a die nozzle 1-3, the rear end of the core body 1-2 is provided with a threaded end, and the threaded end is connected with the discharge port of the extruder, the entire core is hollow, and an inner conductor threading hole 1-4 is provided.

[0024] The foaming extrusion mold sleeve 2 is provided with a tapered hollow hole 2-3, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com