Passive mechanical arm collector

A mechanical arm and passive technology, applied in the direction of current collectors, non-rotating current collectors, circuits, etc., can solve problems such as rigid movements, glides, and difficulty in ensuring the level of the bottom surface, and achieve improved safety, balanced pressure, and balanced contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

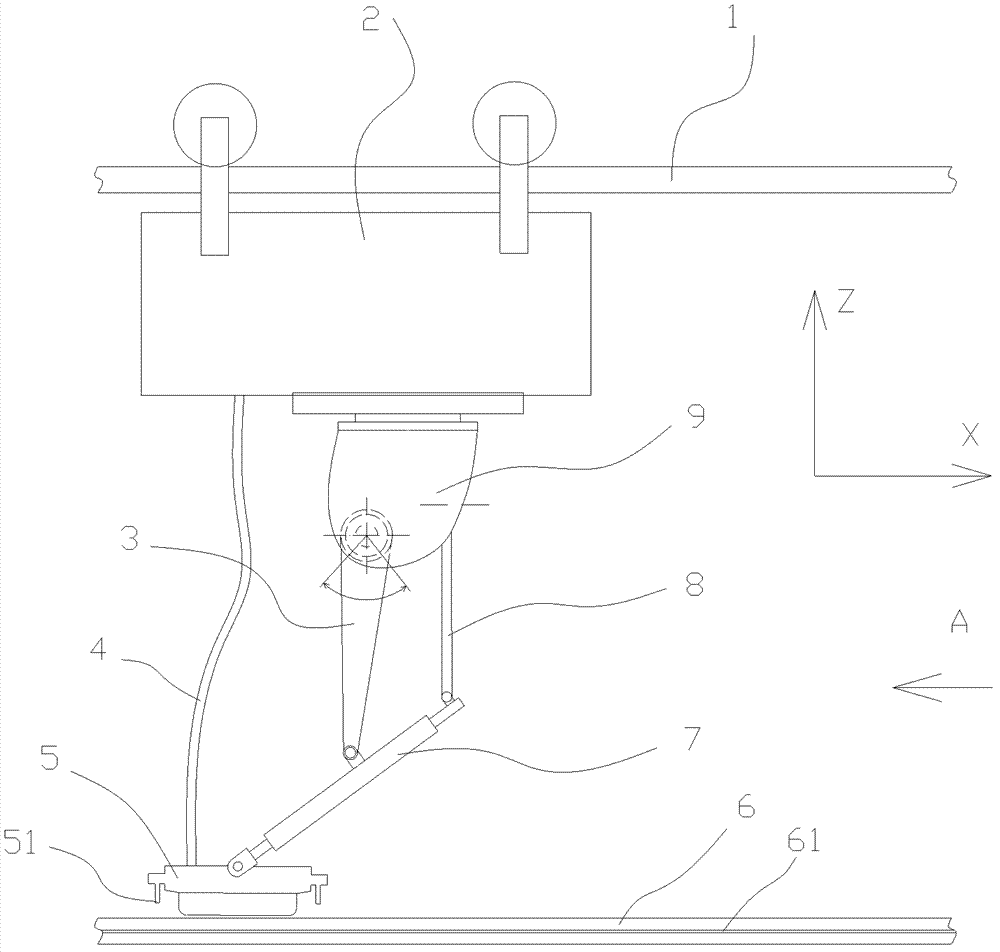

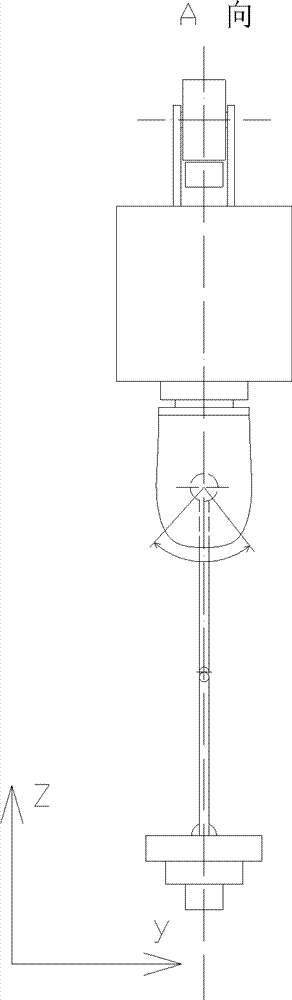

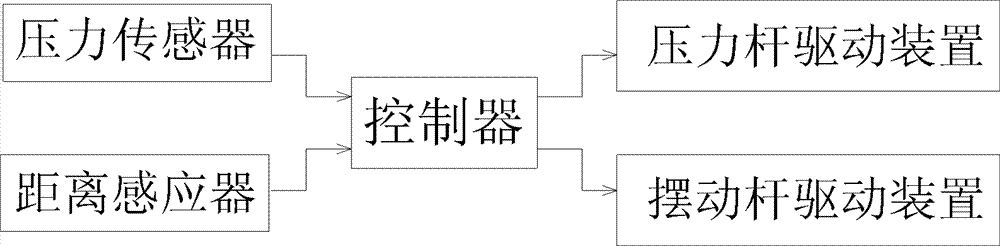

[0022] Such as Figure 1-3 As shown, the present invention includes a trolley 2 running on a guide rail 1, a conductive belt 4, a collector arm 7 and a block-shaped brush 5 kept in contact with the trolley line 6, and the collector arm 7 is connected to the collector arm 7 through a passive mechanical device. The trolley 2 is connected; the passive mechanical device includes a housing 9, a controller, a pressure rod 3 and its driving device, a swing rod 8 and its driving device, a pressure sensor and a distance sensor 51;

[0023] The housing 9 is fixedly connected to the trolley 2, and the controller, the pressure rod driving device and the swing rod driving device are arranged in the housing 9; the two ends of the pressure rod 5 are respectively connected to the between the pressure rod driving device and the middle part of the collector arm 7; the two ends of the swing rod 8 are respectively connected between the swing rod drive device and the tail of the collector arm 7 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com