Control system for novel mining lithium iron phosphate switched reluctance electric locomotive

A switched reluctance, control system technology, applied in the direction of a single motor speed/torque control, electric vehicles, current collectors, etc., can solve the problems of increased cost, power consumption, high cost, prevent explosion, reduce failure rate, high linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

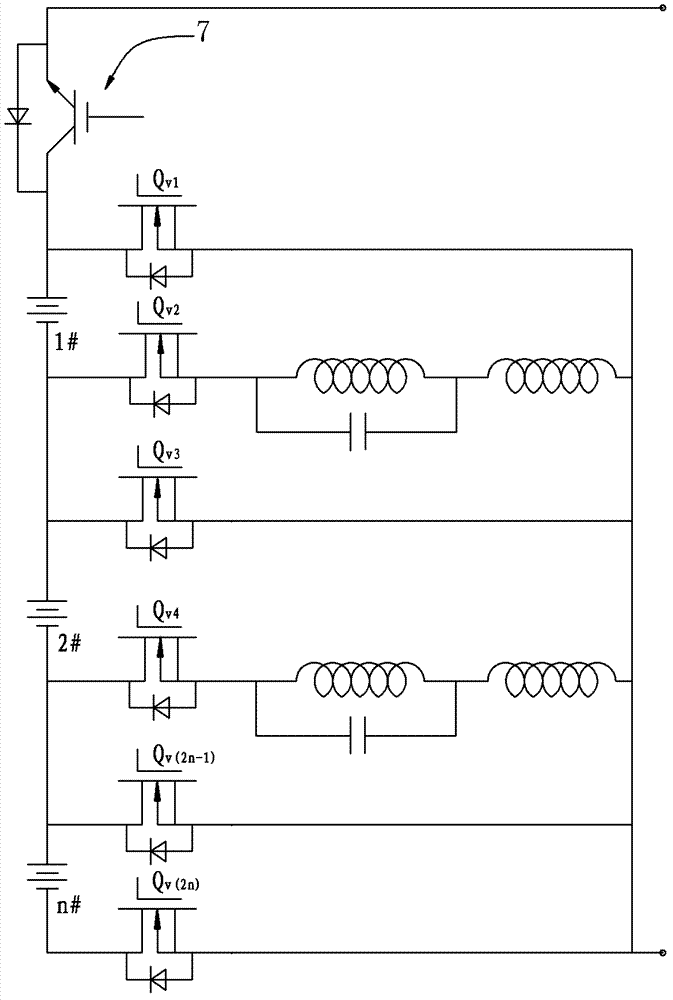

[0016] Combine below Figure 1 to Figure 4 The present invention is described in detail:

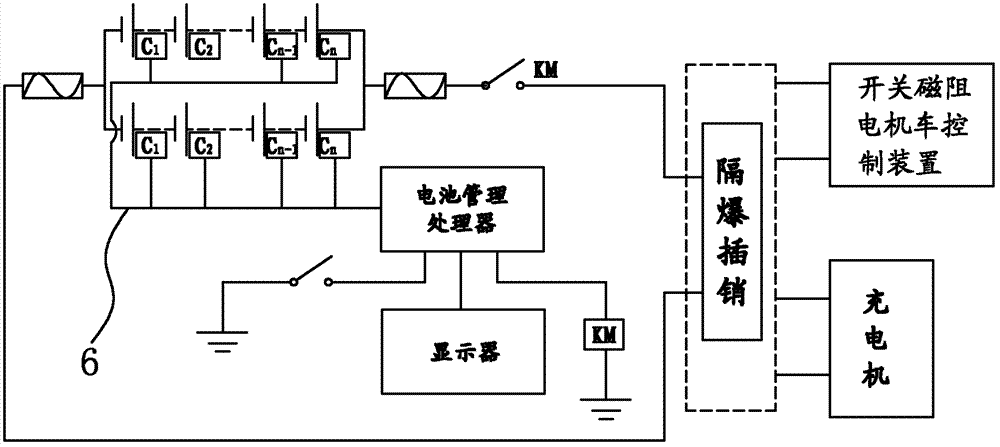

[0017] The switched reluctance electric locomotive management and control system includes a battery pack management device, a switched reluctance electric locomotive control device, and a charger that are respectively connected to flameproof plugs.

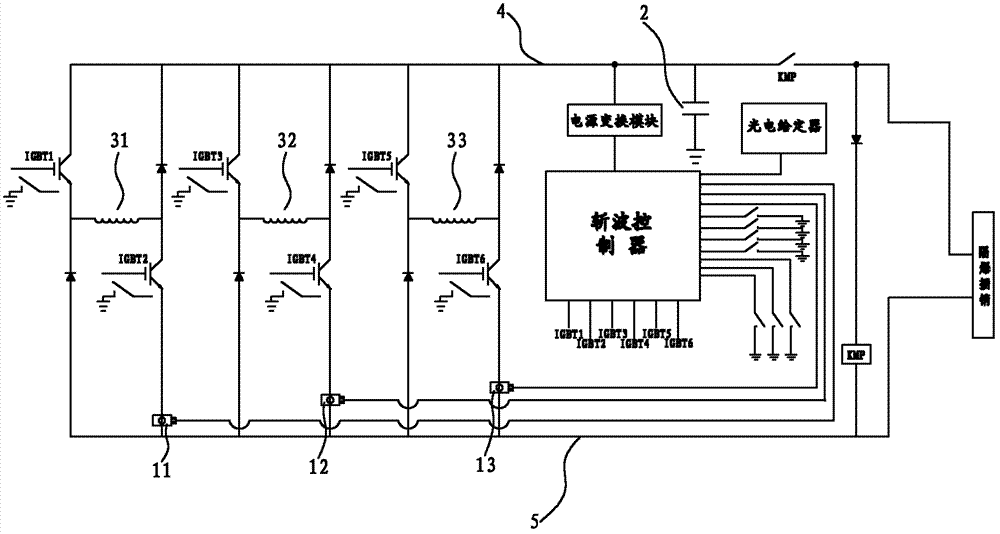

[0018] Switched reluctance electric locomotive control device, including chopper controller, photoelectric given device, power conversion module, three Hall current sensors 11, 12, 13, six insulated gate bipolar transistors IGBT1, IGBT2, IGBT3, IGBT4 , IGBT5, IGBT6, charging capacitor 2, a DC contactor KMP, motor A phase winding terminal 31, motor B phase winding terminal 32, motor C phase winding terminal 33 and two paths 4,5. The photoelectric given device and the voltage conversion module are respectively connected to the chopper controller, the gates of the six insulated gate bipolar transistors IGBT1, IGBT2, IGBT3, IGBT4, IGBT5 and IGB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com