Method for determining fittings for constant tables of automatic placement machines

A workbench, automatic machine technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of unsatisfactory results and high time consumption, and achieve the effects of reducing storage requirements, optimizing manufacturing processes, and reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

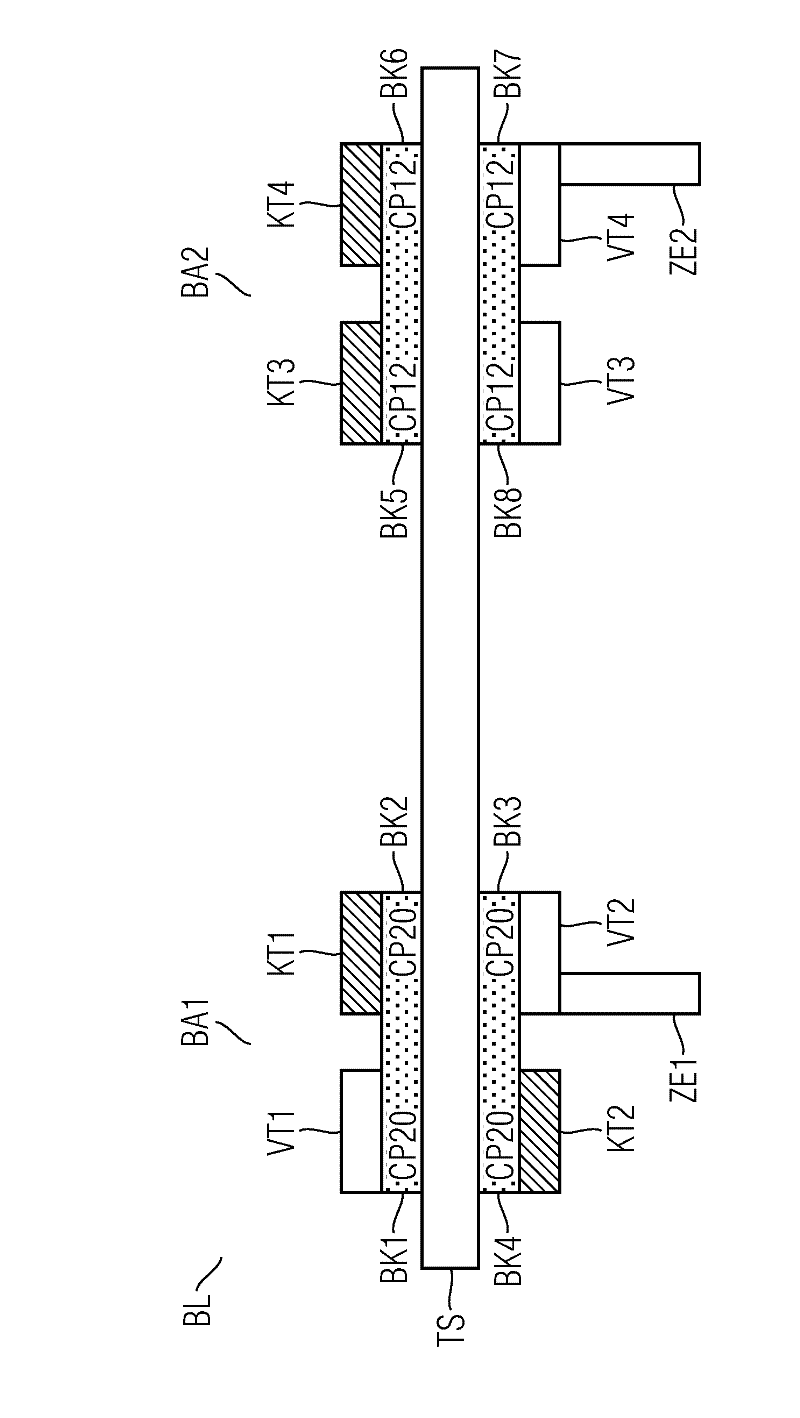

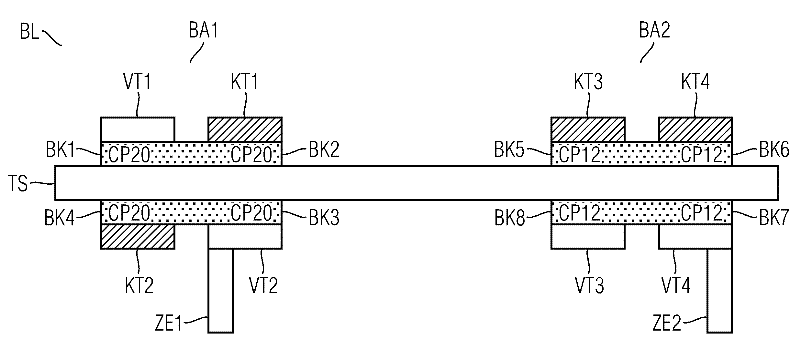

[0036] figure 1 An exemplary expansion of an assembly line BL with two assembly robots BA1 and BA2 , which are arranged on a transport system TS (for example a conveyor belt), is shown.

[0037] The assembly robot BA1 consists of 4 transfer tables KT1 , KT2 , VT1 , VT2 , two of which are variable tables VT1 , VT2 and two of which are constant tables KT1 , KT2 . Furthermore, the assembly robot BA1 consists of four assembly heads BK1-BK4 each of the CP20™ type. The assembly heads BK1-BK8 of the assembly robot BA1, BA2 pick up components from the conveyors ZE1, ZE2 and move these components to the assembly area of the assembly robot BA1, BA2, where substrates to be assembled are provided (e.g. in SMD manufacturing substrate), and the components are placed on the substrate. Assembly heads BK1-BK8 are generally movable by positioning systems. As the conveyor devices ZE1 , ZE2 for supplying components, for example, a so-called belt feeder can be used.

[0038] An assembly robo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com