Composite roll forming process of thick-wall deep-groove ring member

A composite rolling and forming process technology, applied in metal rolling, manufacturing tools, metal rolling and other directions, can solve the problems of many process parameters, mutual influence, waste, defective products and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

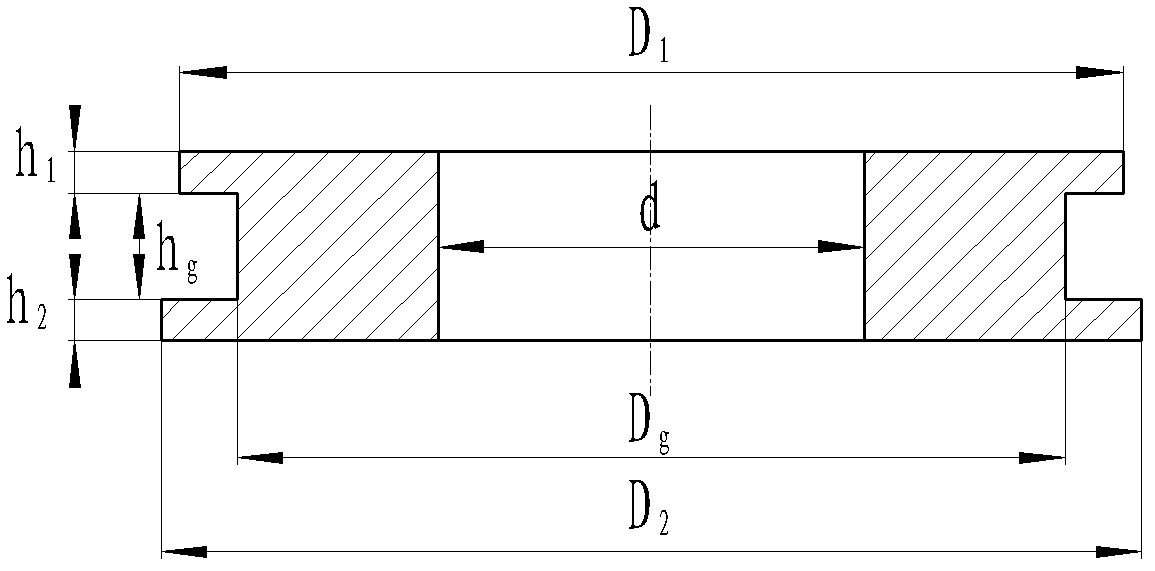

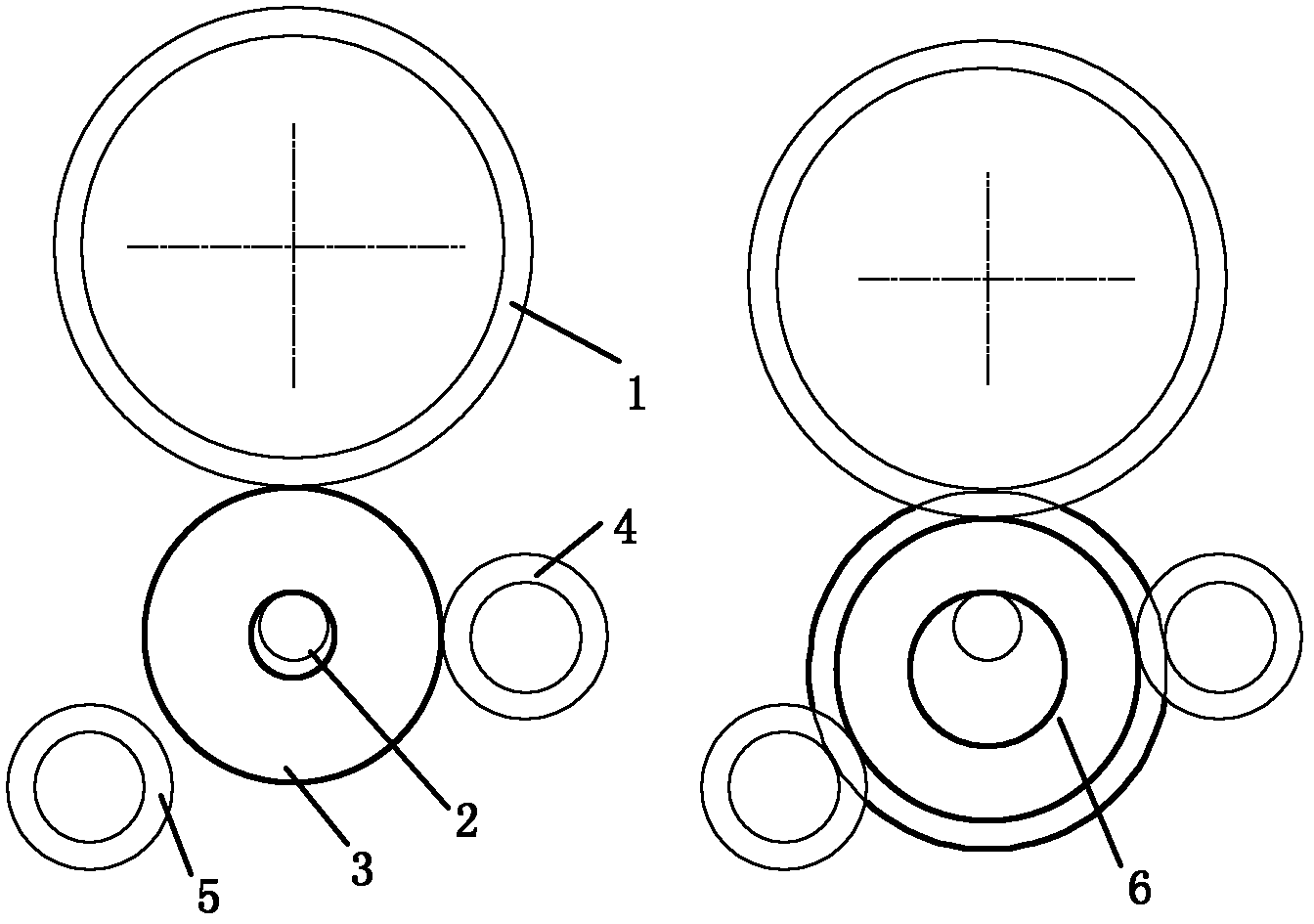

[0114] by figure 1 The duplex gear shown is a specific embodiment, and the diameter of the step on the roll-formed ring is required to be D 1 , Groove diameter D g , the diameter of the lower step D 2 and the inner diameter d are 248mm, 258mm, 218mm and 112mm respectively, and the height of the step on the ring is h 1 , Groove height h g and the lower step height h 2 They are 11mm, 28mm, and 11mm respectively, and the design method of the compound rolling forming process includes the following steps:

[0115] (1) Billet making

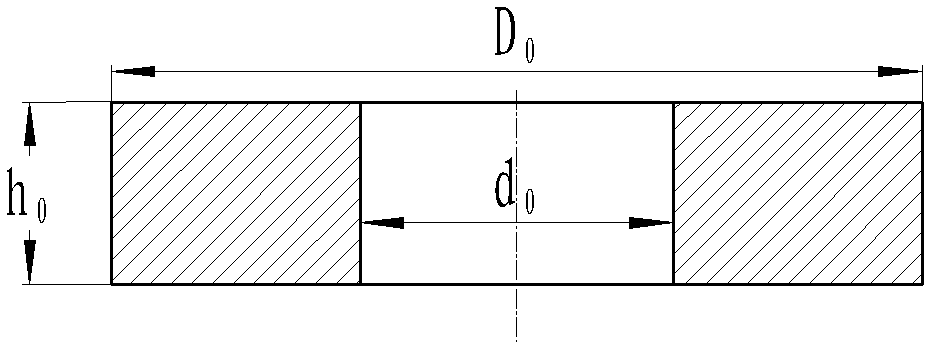

[0116] The shape of the ring blank is image 3 For the ring with rectangular cross-section shown, according to the design method of the ring blank size, the rolling ratio k is taken as 1.3, and the outer diameter of the ring blank for rolling is designed to be D 0 , inner diameter d 0 and height h 0 They are 222.86mm, 86.15mm and 50mm respectively. According to the size of the designed ring blank, the bar section (the specific material is GCr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com