Sliding filling block for accurately positioning large part

A technology for precise positioning and large parts, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve problems such as rack rebound, thin rack boards, scrapped parts, etc., to avoid distortion and reduce labor Strength and the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

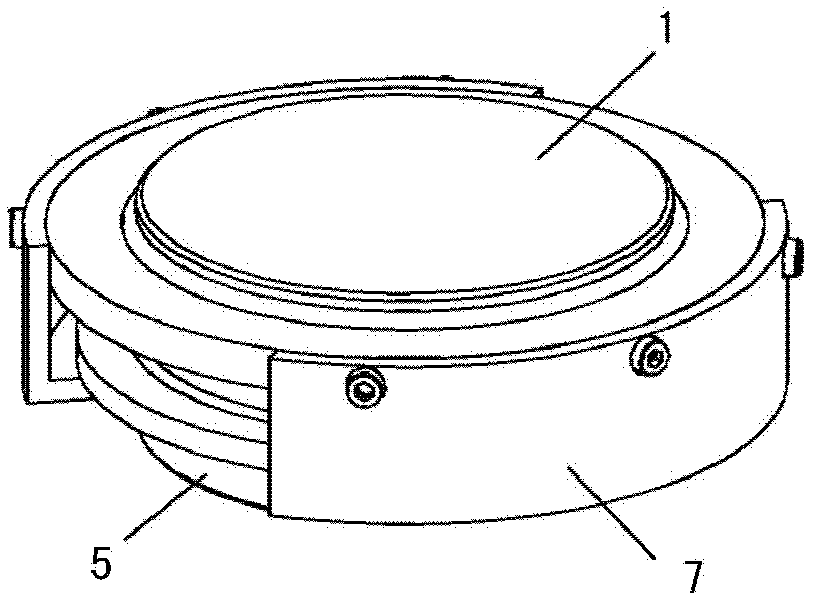

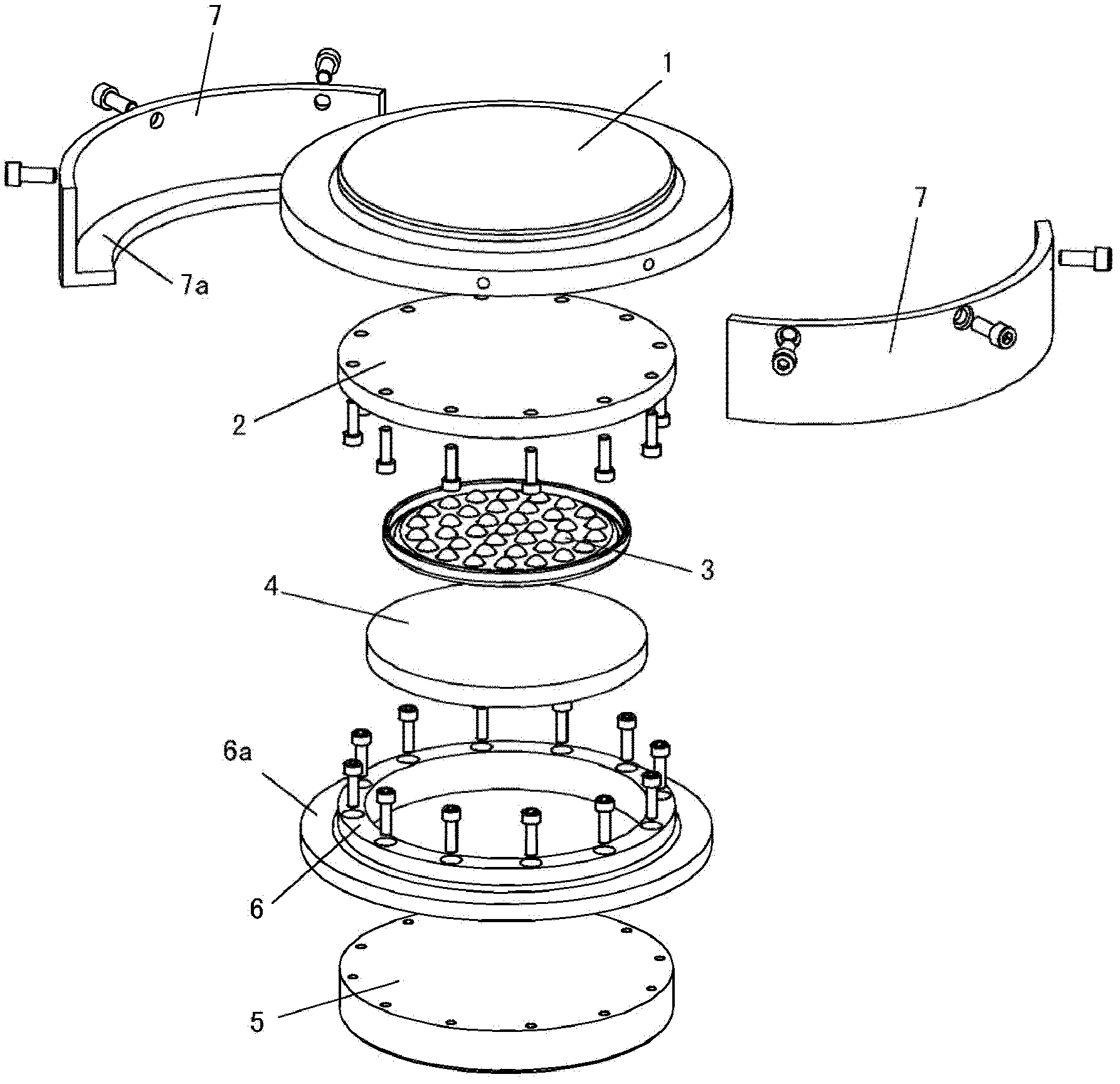

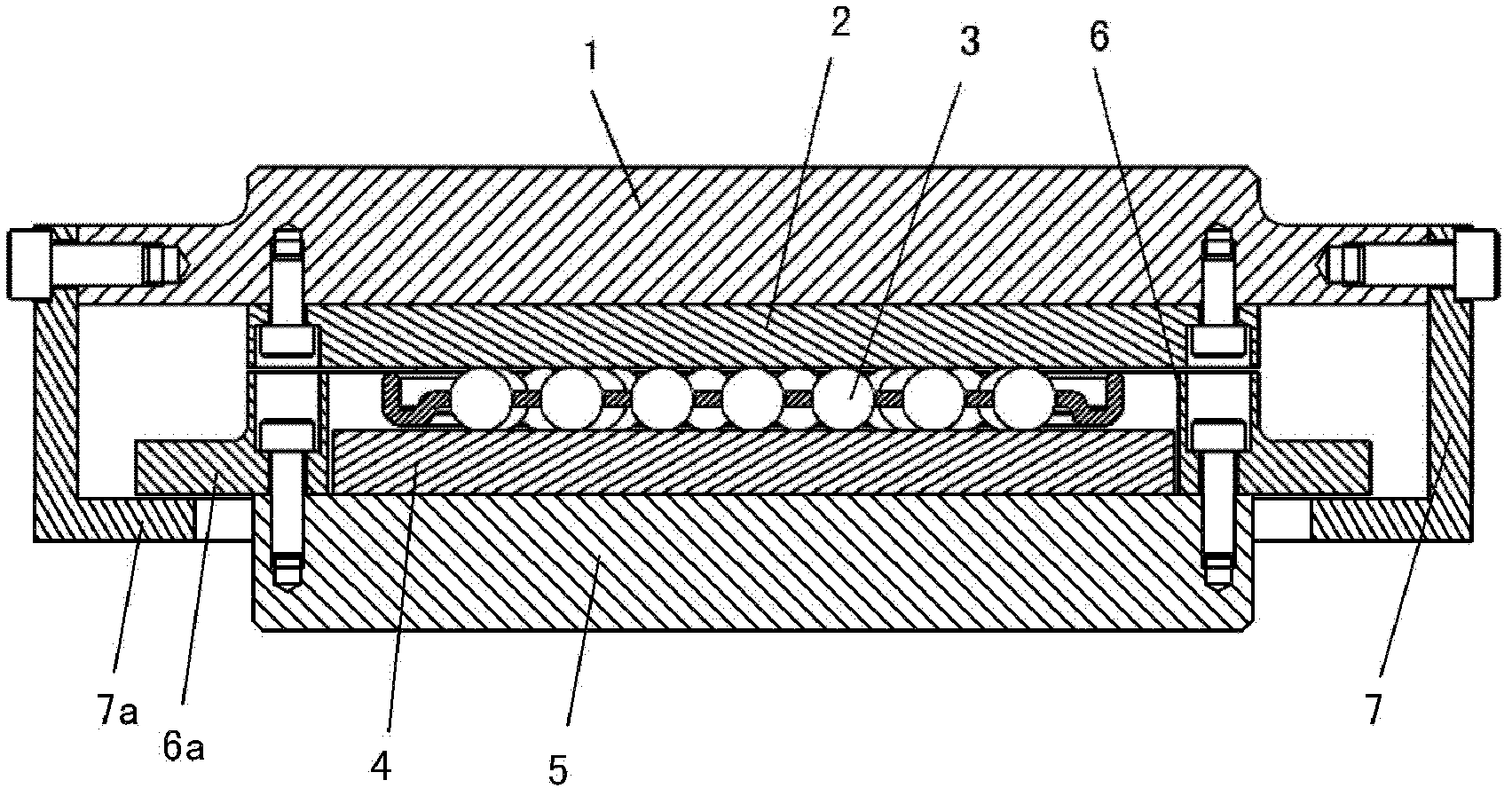

[0018] see figure 1 , figure 2 and image 3 In this embodiment, the structural form of the sliding block for precise positioning of large parts is that the chassis seat 5 and the intermediate ring sleeve 6 are fixedly connected to form a disc-shaped cavity, and the bottom plate 4 and the ball 3 are placed in the disc-shaped cavity. Placed on the upper plane of the bottom plate 4; the upper slide plate 2 supported by the ball 3 is fixedly connected with the top platform 1; the ring side plate 7 is fixed on the periphery of the top platform 1, and the ring side plate 7 forms a pair of chassis seats 5 and the middle. The annular position limiting of the ring sleeve 6, the ring side plate 7 can be made of two tile-shaped side plates, one left and one right symmetrically arranged. The ring side plate 7 not only provides the space for the free movement of the sliding pad, but also restricts this space to a certain extent.

[0019] In specific implementation, an inner flange 7a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com