Rubber special pipe processing technique

A processing technology and special-shaped tube technology, which is applied in the field of small-batch and multi-variety rubber special-shaped tube processing technology, can solve the problems of long production cycle of small-batch products, variable size of sample parts, and inability to mass-produce, etc., to achieve easy operation of equipment, The effect of simple equipment and high production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

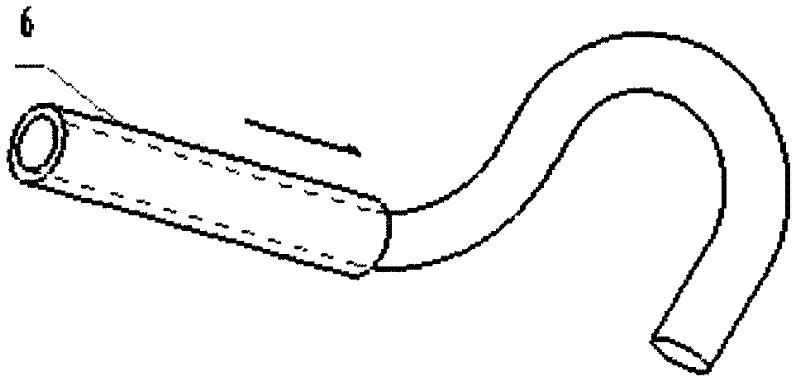

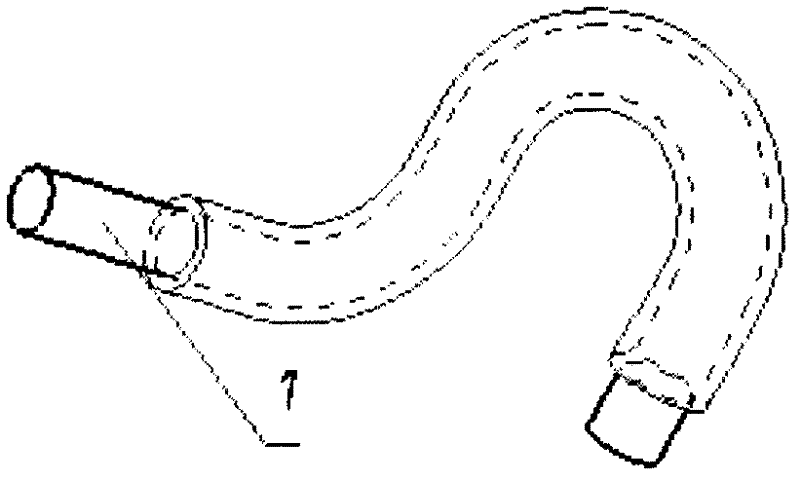

[0023] will now refer to Figure 1-6 Preferred embodiments of the present invention will be described in detail.

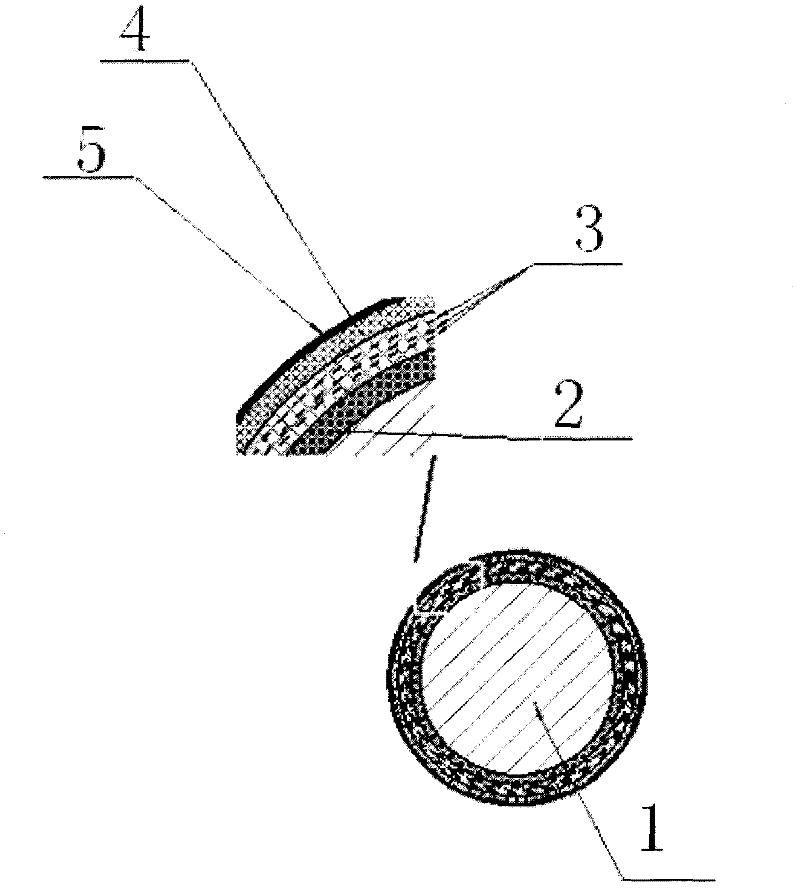

[0024] see figure 1 ,in figure 1 The upper left part is an enlarged cross-sectional view of a straight rubber tube covered with a polyester film 5, a process for processing rubber shaped tubes, including the following steps:

[0025] see figure 1 , according to the requirements of product inner diameter, wall thickness, length and blasting pressure, wrap the inner layer rubber 2, the skeleton layer 3 and the outer layer rubber 4 on the straight pipe core 1 to form a rubber straight pipe on the straight pipe core. Straight pipe core and rubber straight pipe are fixed on the machine;

[0026] Coating the pre-prepared polyester film 5 from the straight tube core 1 and one end of the rubber straight tube;

[0027] Put the coated rubber straight pipe and the straight pipe core 1 together into a hot air vulcanization tank for primary vulcanization, and no pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com