Automatic stirring and supplying device for ball press

An automatic mixing and feeding device technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of inconsistent coal weight, time-consuming and labor-intensive manual feeding, and too fast feeding, so as to shorten downtime, save manpower and cost, ease of quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

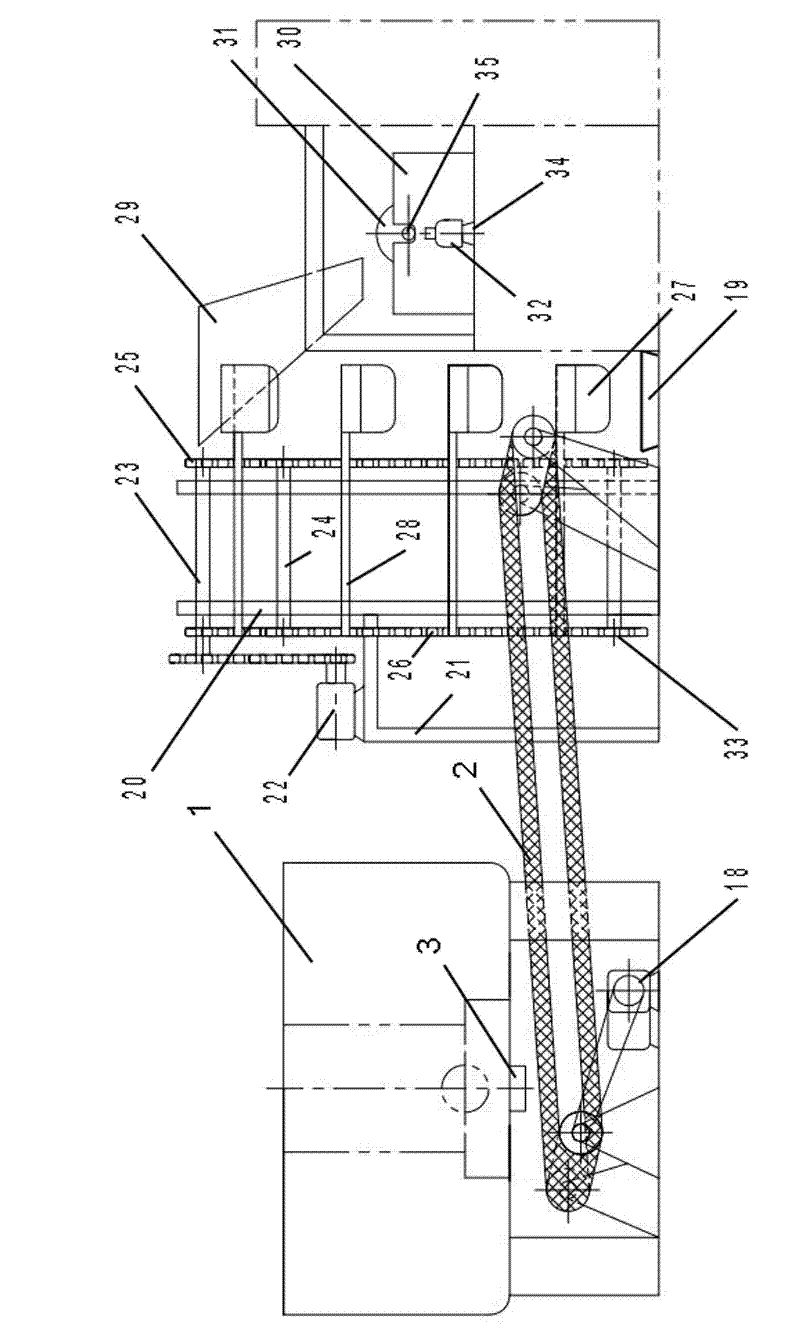

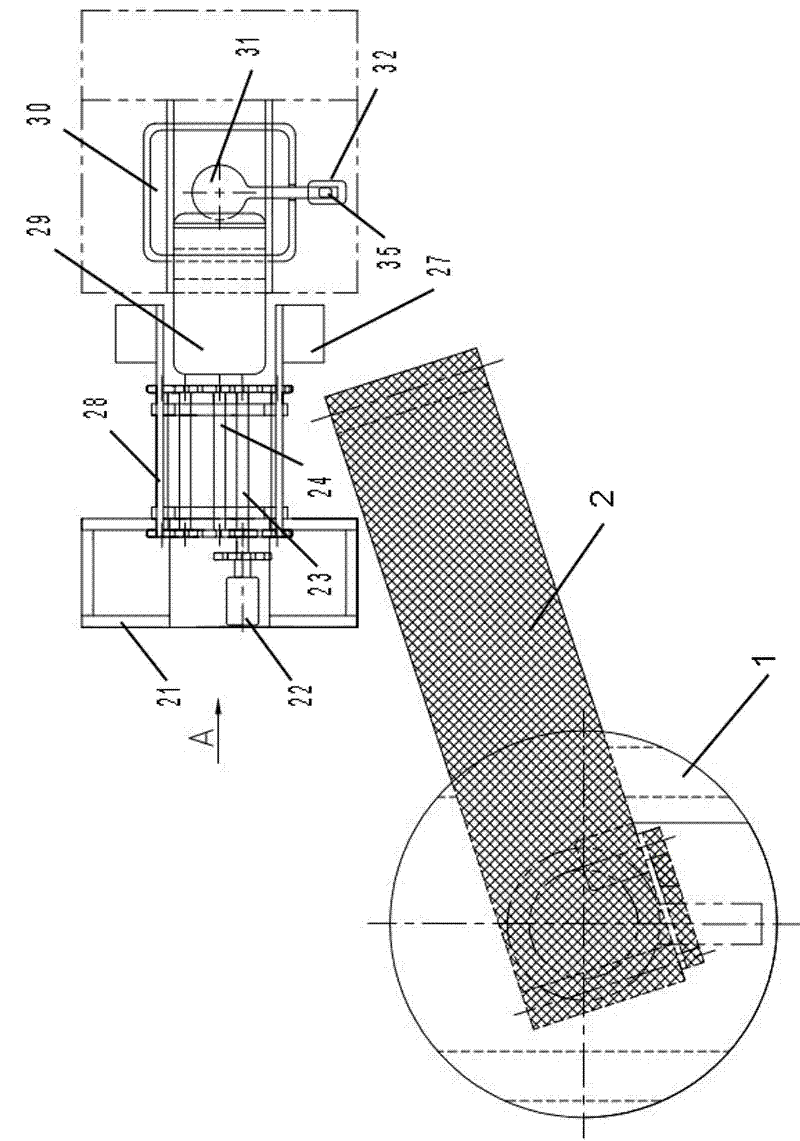

[0026] Such as figure 1 , 2 As shown, the present invention includes a feed bin 1, a conveyor and a feeding assembly. figure 1 , 2 The structure in silo 1 is not expressed in detail due to the scale of the drawing. For the specific structure in silo 1, see image 3 , 4 .

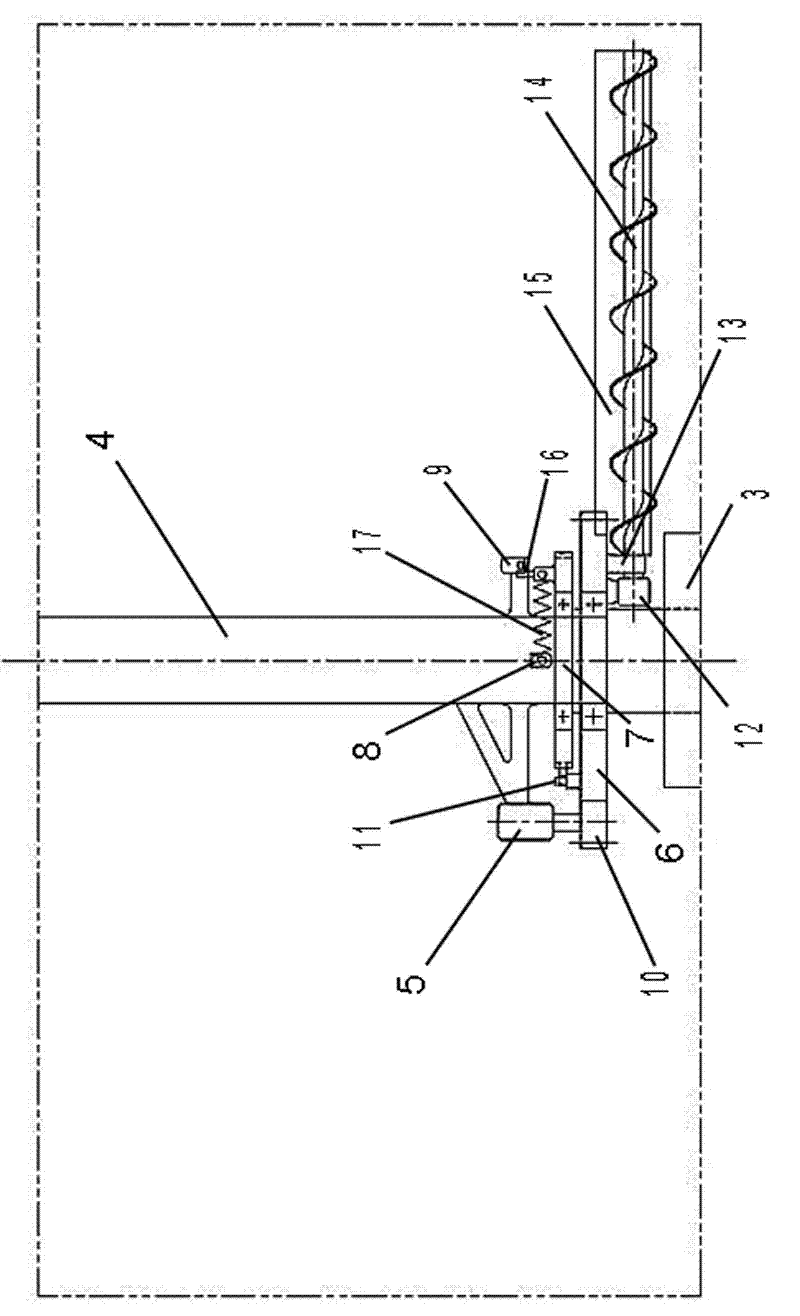

[0027] Such as image 3 , 4 As shown, the silo 1 is cylindrical with an upper opening, and the bottom of the silo 1 is provided with a discharge opening 3 in the middle.

[0028] In the middle of the silo 1, there is a silo central axis 4 fixed on the silo 1, and a stirring motor 5, a rotating disk 6, a ratchet 7, a spring fixing card 8, and a travel switch 9 are installed on the silo central axis 4.

[0029] The stirring motor 5 is connected with the central shaft 4 of the feed bin through the motor frame, and the stirring motor 5 is linked with a driving gear 10, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com