Front cabin element fixing structure for electric vehicle

A fixed structure, electric vehicle technology, applied in the direction of vehicle components, electric power devices, power devices, etc., can solve the problems of low rigidity and difficulty in meeting the rigidity requirements of the front cabin, so as to improve performance and competitiveness and reduce discount The risk of bending and the effect of ensuring Z-direction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

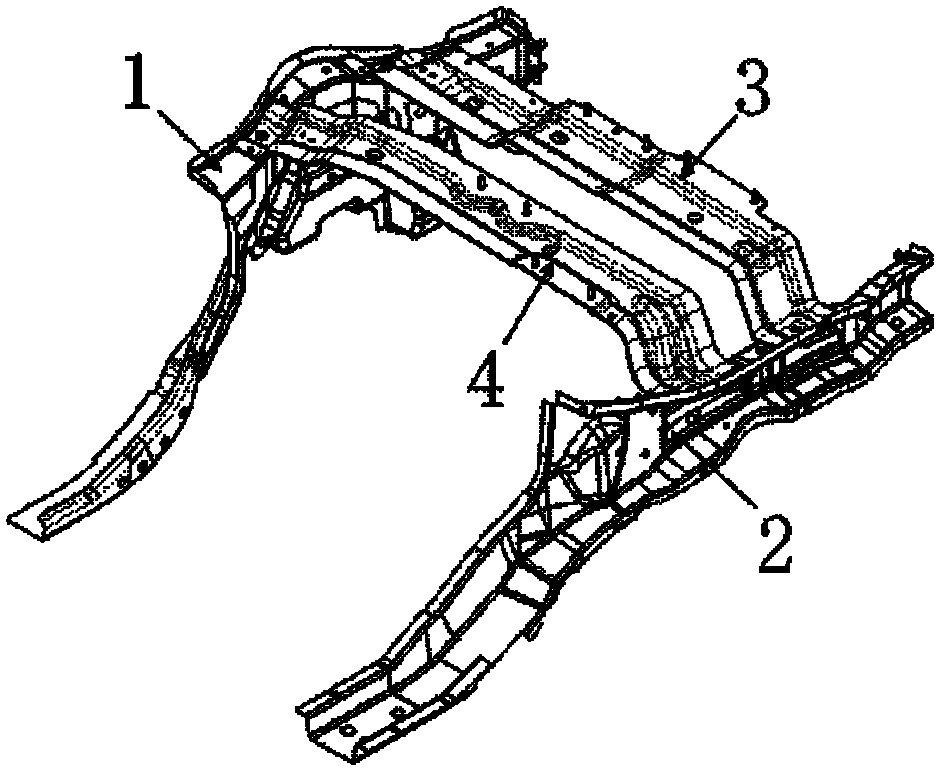

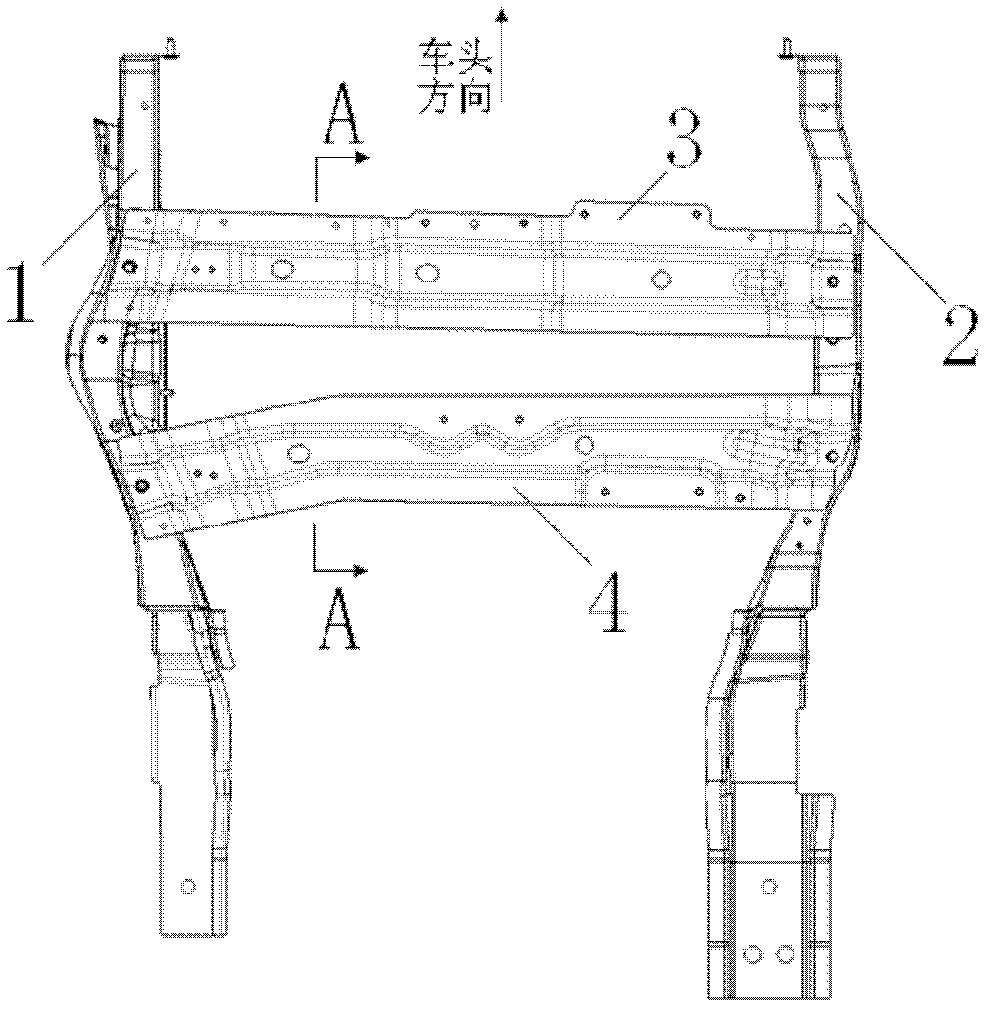

[0019] Such as Figure 1 to Figure 4 As shown, an electric vehicle front cabin element fixing structure includes left and right longitudinal beam assemblies arranged on both sides of the front cabin, namely, a first front longitudinal beam assembly 1 and a second front longitudinal beam assembly 2; Between the first front longitudinal beam assembly 1 and the second front longitudinal beam assembly 2, there are a front cabin front inner cross member assembly 3 and a front cabin rear inner cross member assembly 4 for fixing elements in the front cabin. The cross beam assembly 3 and the front rear inner cross beam assembly 4 are arranged side by side. The connection between the left and right side beam assemblies is strengthened, and the rigidity of the vehicle, especially the front cabin, is improved.

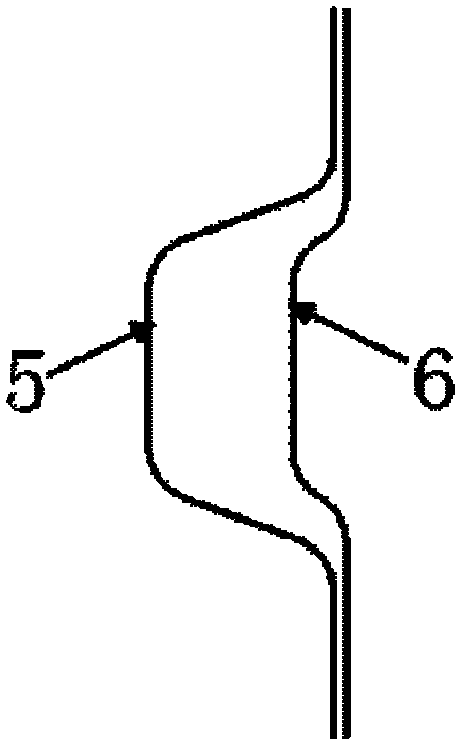

[0020] In order to facilitate installation and maintenance, both ends of the front inner cross beam assembly of the front cabin and the rear inner cross beam assembly of the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com