Integral structure type propeller hub for ship

A technology of integral structure and propeller, which is applied in ship propulsion, propulsion parts, ship parts, etc., can solve the problems of small force bearing area of the piston, increase the risk of hydraulic system leakage, and affect the operation of the mechanism, so as to improve the stiffness and strength, The effect of reducing the strength requirement and improving the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

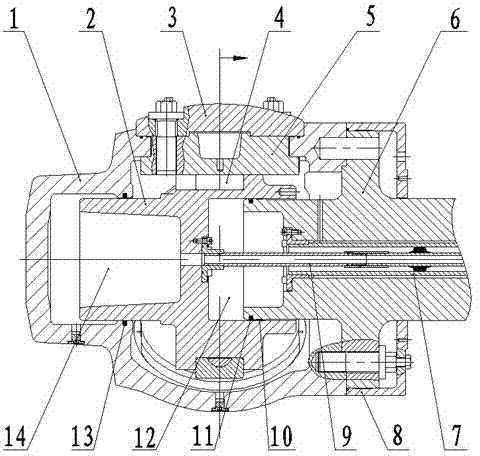

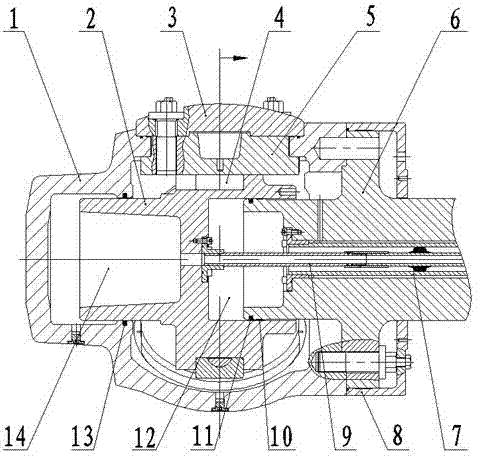

[0011] The present invention will be further described below in conjunction with the accompanying drawings. figure 1 As shown, the present invention is mainly composed of a hub body 1, a guide frame 2, a slider 4, a blade seat 5, and a paddle shaft 6. The hub body 1 is integrated with an oil cylinder body, and the front end of the hub body 1 Use high-strength flange bolts to connect with the paddle shaft 6; the paddle hub body 1 is provided with a movable guide frame 2, the guide frame 2 is integrated with the piston, and its front end is used as an oil cylinder with an oil chamber. The rear end is used as the piston of another oil chamber, and the inner diameter of the front end is equal to the outer diameter of the rear end; the paddle shaft 6 is installed in the front end of the guide frame, and the rear end of the guide frame is installed in the rear part of the hub body. The outer wall of the middle part of the guide frame 2 is provided with a chute equipped with a slider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com